The single heat treat recevers were made from WD1325. So were the double heat treat. This is a low grade material with inferior properties to alloy steels.

Looking at data on Matweb, the low carbon steel used in these early receivers is not used for complicated parts, unheated it is used for rebar, if heat treated for medium duty shafts, studs, bolts and nuts. I did a composition search and found AISI 1117-1118 steel, which is similar in composition to Springfield Armory Class C steel. I could not find something that was just carburized and quenched , I found data for 1 inch round AISI 1118 mock carburized, reheated to 1450 F, quenched, tempered. This is similar to the double heat treatment. The Ultimate strength is 103,000 psi, yield 59,300 psi, elongation at break 19%. For something similar to WD2340 Nickel steel, I found one inch round AISI 4820. For that material, mock carburized, 1450 F reheat, water quench, the ultimate strength was 163,000 psi and the yield strength was 120,000 psi, elongation at break 15%. Many modern receivers are made from 4140. For a 1 in round AISI 4140 Steel, normalized at 870°C (1600°F), reheated to 845°C (1550°F), oil quenched, 260°C (500°F) temper, ultimate strength 270,000 psi, yield 240,000 psi, elongation at break 11%.

The margin of strength in modern firearms is just so much better than what you will find in these early plain carbon steel receivers.

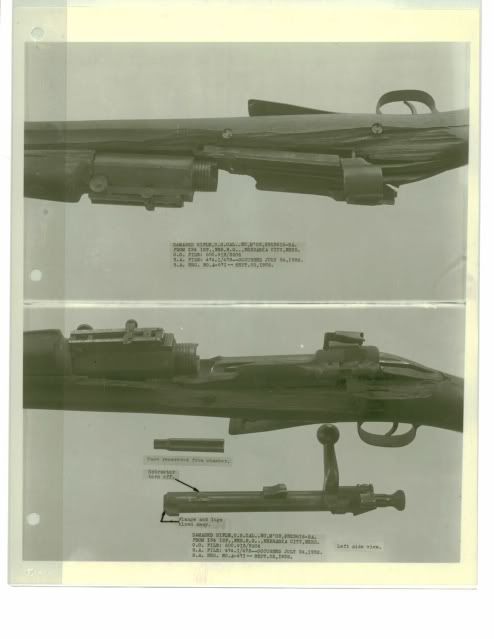

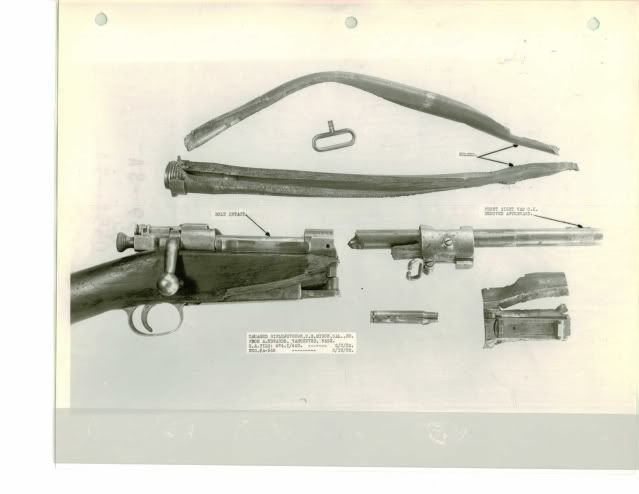

Not only do the plain carbon steel M1903’s have low margin of strength, the action has virtually no shooter protection features. Gas goes everywhere, the stock gets blown, hot gas goes straight down the firing pin shaft into the shooter’s eyes, it can be very bad.

There is a long thread with pictures of a blown single heat treat at this URL.

http://www.jouster.com/forums/showthread.php?14045-Blown-03-Receiver-From-GB&p=136820#post136820

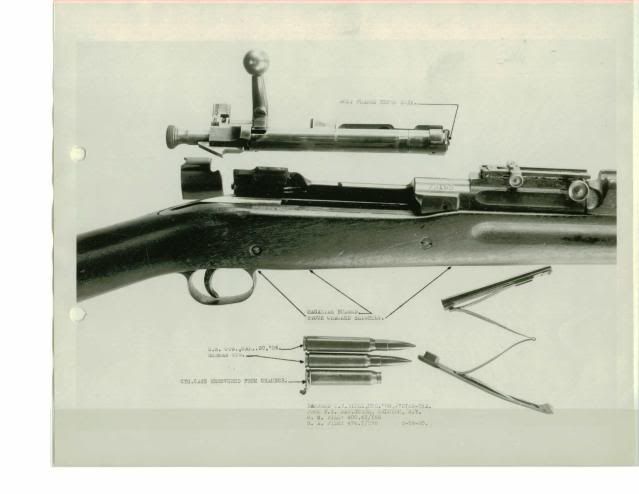

These pictures came from Springfield Armory. Just see how these plain carbon steel receivers frag’d.

In my opinion, single heat treat receivers are just not worth the risk. The Army eventually pulled them, because there is no non destructive way to determine good from bad. If it was as simple as a hardness test, they would have done it.