You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sizing questions?

- Thread starter axis223

- Start date

603Country

New member

Axis, Go back to where Mr Guffey mentioned sizing the case to fit, rather than sizing it as much as the die allows. That's the part of all this discussion that you should have paid special attention to. You want to size the fired case as little as possible to get it to fit the rifle chamber. If you do that, you limit case stretch in repeated firings. Limiting repeated case stretch allows longer case life.

So here's how you can fit the case to chamber without buying more stuff. Take a reloaded case or two and fire them. Back the FL die out until you size only half of the neck (you'll be able to tell by looking how much neck is getting sized) and reload and fire. Do this until the resized cases become noticeably tougher to chamber. Now, screw the FL die in a turn and resize those two empty cases and see if they chamber easily. If not, screw the die in half a turn. Repeat till those cases chamber easily. Now, lock down the ring on the die and it is set for use.

So here's how you can fit the case to chamber without buying more stuff. Take a reloaded case or two and fire them. Back the FL die out until you size only half of the neck (you'll be able to tell by looking how much neck is getting sized) and reload and fire. Do this until the resized cases become noticeably tougher to chamber. Now, screw the FL die in a turn and resize those two empty cases and see if they chamber easily. If not, screw the die in half a turn. Repeat till those cases chamber easily. Now, lock down the ring on the die and it is set for use.

condor bravo

New member

Reply to MG post #20:

Well yes I think the flexibility issue allowing excessive stretching is a possibility; about the only thing I can come up with also. And since the cases were used, no telling what they had been subjected to. Probably overloads. All subsequent loadings have been with new brass and what I consider to be reasonable loads with no additional problems. At any rate the cause would seem to be slightly different than with standard bottlenecks.

Well yes I think the flexibility issue allowing excessive stretching is a possibility; about the only thing I can come up with also. And since the cases were used, no telling what they had been subjected to. Probably overloads. All subsequent loadings have been with new brass and what I consider to be reasonable loads with no additional problems. At any rate the cause would seem to be slightly different than with standard bottlenecks.

One thing that happens with neck sizing-only is that it normally allows the case to grow a little with each firing. Most folks have to full-length resize after several neck-only loadings because the case finally will no longer chamber freely. Brass has a limited elasticity, and normal pressures will stretch both the brass and the chamber a little. The chamber returns to size because steel is more elastic (a better spring) than brass is. But the brass has only a percentage of return to size, and because it is starting a little larger at every firing, that percentage gets smaller at each firing.

If you are running at very low pressures with a heavy enough chamber wall and rigid enough bolt lugs, then the steel won't expand enough under pressure to let the brass expand. In that instance you may wear the case out before it needs full length resizing.

DANGER WILL ROBINSON!

You may get away with it with very low pressure loads for the above reasons, or having a particularly forgiving feed, but, generally speaking, neck sizing-only is a dangerous practice in any self-loading gun with a floating firing pin, as it is just asking for a slamfire or for an out-of-battery firing if your cases are expanding with every load cycle. Here are two photos I got just two weeks ago from a board member who had an OOB fire in his M1 Garand because of using neck sizing-only.

That OOB fire drove the case back against the bolt face pushing the bolt back so hard it slammed into the receiver with some velocity, causing this result:

The bottom line is, neck sizing-only for a self-loading, floating firing pin gun is a risky practice. Getting away with it could well be just happenstance at work in your favor. It cannot be counted on to continue to cooperate. Most folks have never had a bad car crash, but that doesn't mean they can't, nor that it is pointless to take precautions against having one.

General things about resizing:

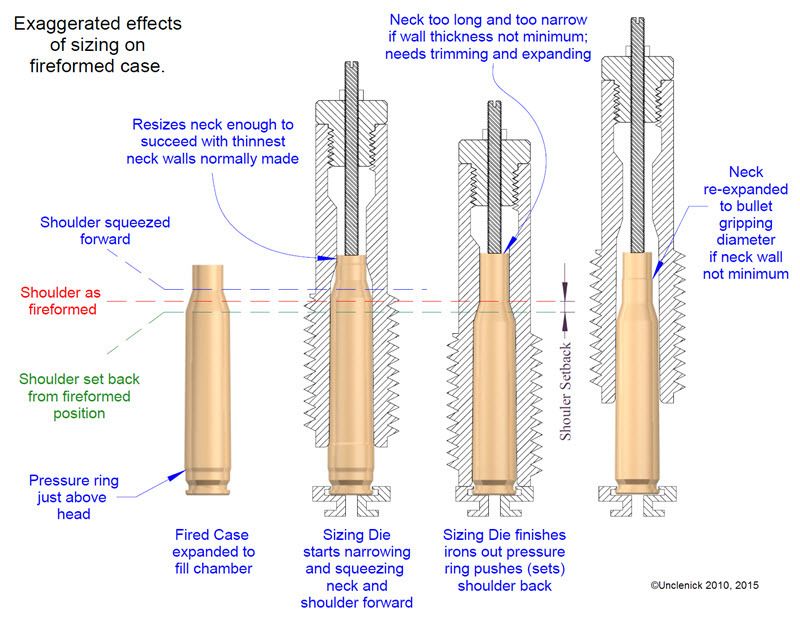

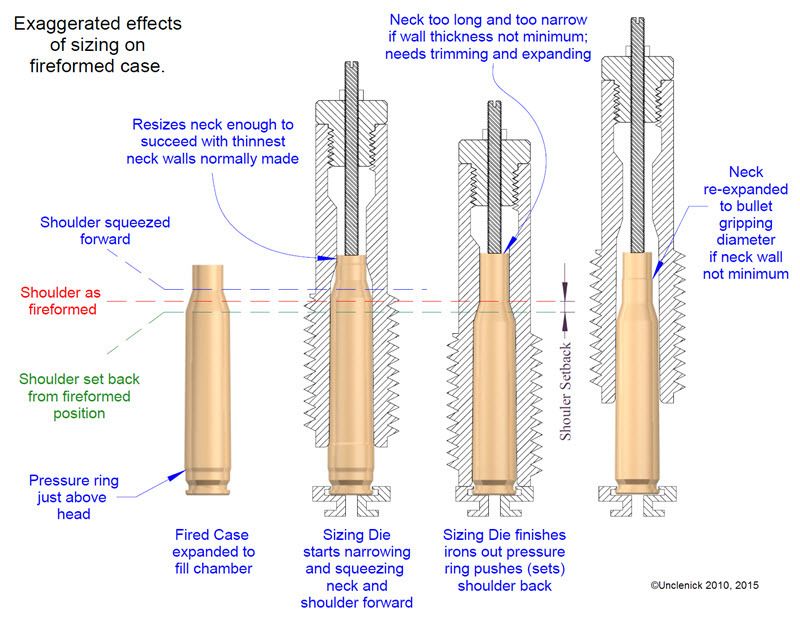

Below is an exaggerated view of what happens to a bottleneck rifle case during resizing in a full-length die. First, the sides of the die contact the brass, causing it to extrude slightly to a greater length. If you withdraw a case from a die before the shoulder of the case contacts the shoulder of the die, you will find the shoulder-to-head length has grown.

Next, the shoulders of the case and die make contact. It is at this point the die starts to form the shoulder back to the desired position.

If the sizing die pushes the shoulder back as far as it can, the result is full length resizing. If the die is set up to push the shoulder back only a thousandth or two shorter than the chamber length, it is called "bump" sizing (a term I don't like either, though it is less of a mouthful than "partial shoulder set-back). In general, for single-loading about -0.001" is commonly used, while -0.002" is used for guns that are to feed from a a magazine, and is generally considered minimum for self-loaders.

It was once thought neck sizing-only produced the most accurate ammunition, but the consensus among benchrest shooters currently seems to be that setting a shoulder back -0.001" shorter than it came out of the chamber produces best accuracy. This is believed to be because the small amount of loose fit allows the brass to self-center the bullet when the firing pin drives the round forward as it works to ignite the primer. A neck sized-only case, if it includes any imperfection in wall symmetry, will tend to expand more on its thin side, and then hold the neck slightly off center in the chamber. Self-centering corrects that, and even though the case may expand asymmetrically again under pressure, the inertia of the bullet mass keeps the case from moving it appreciably out of line before the neck has expanded, too, letting go of it.

A technique I've been using for awhile now with precision loads is to resize the case body and set the shoulder back in a Redding Body Die, then neck size in the Lee Collet Die. This two-step sizing give me control of the case body and the Lee Die gives me runout-free necks with consistent ID, regardless of how thick the neck wall is.

If you are running at very low pressures with a heavy enough chamber wall and rigid enough bolt lugs, then the steel won't expand enough under pressure to let the brass expand. In that instance you may wear the case out before it needs full length resizing.

DANGER WILL ROBINSON!

springer99 said:…I've neck-sized only in my M1's forever to save wear and tear on the cases; something that's normally not suggested on semi-auto's. I've had no problems.

You may get away with it with very low pressure loads for the above reasons, or having a particularly forgiving feed, but, generally speaking, neck sizing-only is a dangerous practice in any self-loading gun with a floating firing pin, as it is just asking for a slamfire or for an out-of-battery firing if your cases are expanding with every load cycle. Here are two photos I got just two weeks ago from a board member who had an OOB fire in his M1 Garand because of using neck sizing-only.

That OOB fire drove the case back against the bolt face pushing the bolt back so hard it slammed into the receiver with some velocity, causing this result:

The bottom line is, neck sizing-only for a self-loading, floating firing pin gun is a risky practice. Getting away with it could well be just happenstance at work in your favor. It cannot be counted on to continue to cooperate. Most folks have never had a bad car crash, but that doesn't mean they can't, nor that it is pointless to take precautions against having one.

General things about resizing:

Below is an exaggerated view of what happens to a bottleneck rifle case during resizing in a full-length die. First, the sides of the die contact the brass, causing it to extrude slightly to a greater length. If you withdraw a case from a die before the shoulder of the case contacts the shoulder of the die, you will find the shoulder-to-head length has grown.

Next, the shoulders of the case and die make contact. It is at this point the die starts to form the shoulder back to the desired position.

If the sizing die pushes the shoulder back as far as it can, the result is full length resizing. If the die is set up to push the shoulder back only a thousandth or two shorter than the chamber length, it is called "bump" sizing (a term I don't like either, though it is less of a mouthful than "partial shoulder set-back). In general, for single-loading about -0.001" is commonly used, while -0.002" is used for guns that are to feed from a a magazine, and is generally considered minimum for self-loaders.

It was once thought neck sizing-only produced the most accurate ammunition, but the consensus among benchrest shooters currently seems to be that setting a shoulder back -0.001" shorter than it came out of the chamber produces best accuracy. This is believed to be because the small amount of loose fit allows the brass to self-center the bullet when the firing pin drives the round forward as it works to ignite the primer. A neck sized-only case, if it includes any imperfection in wall symmetry, will tend to expand more on its thin side, and then hold the neck slightly off center in the chamber. Self-centering corrects that, and even though the case may expand asymmetrically again under pressure, the inertia of the bullet mass keeps the case from moving it appreciably out of line before the neck has expanded, too, letting go of it.

A technique I've been using for awhile now with precision loads is to resize the case body and set the shoulder back in a Redding Body Die, then neck size in the Lee Collet Die. This two-step sizing give me control of the case body and the Lee Die gives me runout-free necks with consistent ID, regardless of how thick the neck wall is.

Axis :

Sorry should have been more clear . I'm not completely clear what specific part you don't understand so I'll explain it a little more . Adjusting the die per instructions did not do that to my cases because I was able to size and fire them twice with no visibly noticeable issue . How ever after the third firing a got some head separation do to repeatedly sizing my cases shorter then needed to optimally fit my chamber . Meaning in this case and "my" comparator . The ideal case size head to datum is 1.619" but when using my standard Redding FL die and a standard shell holder adjusted per instructions . The cases were sized to 1.611 to 1.610 which is .009 shorter then what is optimal for my chamber . That resulted in leaving the .009 space between the head of the case and the bolt face when fired . Repeatedly firing cartridges with that much head clearance can and will result in case stretch and head separation .

Keep in mind that the manufacturers instructions are not to have a case fit a specific chamber and extend case life . They are so when a case is sized per there instructions . That case will chamber in any rifle with in SAAMI specs . Meaning they would need to fit in a tightly cut chamber at SAAMI minimum specs . In my case and the specific chamber that fired those cases . That chamber is just short of allowing a NO-GO gage from chambering . So altough with in spec , it's a tad on the longer side . So if I size a case to SAAMI minimum , when that case is fired in my rifle the head clearance is not optimal . Repeatedly firing cases that short will result in the cases stretching a little more after each firing until the walls become to thin and they crack and separate .

Sorry should have been more clear . I'm not completely clear what specific part you don't understand so I'll explain it a little more . Adjusting the die per instructions did not do that to my cases because I was able to size and fire them twice with no visibly noticeable issue . How ever after the third firing a got some head separation do to repeatedly sizing my cases shorter then needed to optimally fit my chamber . Meaning in this case and "my" comparator . The ideal case size head to datum is 1.619" but when using my standard Redding FL die and a standard shell holder adjusted per instructions . The cases were sized to 1.611 to 1.610 which is .009 shorter then what is optimal for my chamber . That resulted in leaving the .009 space between the head of the case and the bolt face when fired . Repeatedly firing cartridges with that much head clearance can and will result in case stretch and head separation .

Keep in mind that the manufacturers instructions are not to have a case fit a specific chamber and extend case life . They are so when a case is sized per there instructions . That case will chamber in any rifle with in SAAMI specs . Meaning they would need to fit in a tightly cut chamber at SAAMI minimum specs . In my case and the specific chamber that fired those cases . That chamber is just short of allowing a NO-GO gage from chambering . So altough with in spec , it's a tad on the longer side . So if I size a case to SAAMI minimum , when that case is fired in my rifle the head clearance is not optimal . Repeatedly firing cases that short will result in the cases stretching a little more after each firing until the walls become to thin and they crack and separate .

Last edited:

You may get away with it with very low pressure loads for the above reasons, or having a particularly forgiving feed, but, generally speaking, neck sizing-only is a dangerous practice in any self-loading gun with a floating firing pin, as it is just asking for a slamfire or for an out-of-battery firing if your cases are expanding with every load cycle. Here are two photos I got just two weeks ago from a board member who had an OOB fire in his M1 Garand because of using neck sizing-only.

Unclenick, I am glad the board member sent that case to you because I would have disagreed with him. I have wildcats with longer necks; the shortest is .217”. What that means the case head had to be protruding .225” from the chamber when the out of batter fire happened. In my opinion with any decent load the case head would not have stayed attached because very little if any of the case head was supported by the chamber.

F. Guffey

condor bravo

New member

Per axis' post #23, he apparently still needs to be seeking confirmation on the rcbs die setting adjustment. Let me try this basic approach that seems to be advocated by many and conforms I believe to the rcbs instructions. Screw the seating die down to where it makes contact with the shell holder and then back off some, let's say 1/4 to maybe 1/3 turn. Now size a fired case and see how the case will chamber. If it chambers easily with that adjustment, you should be good to go and can tighten the lock nut. But if it chambers with resistance, that means the case has elongated some and the shoulder needs to be set back some. To do that, screw the die down in small increments and continue sizing and chamber until proper chambering is achieved. If that does not happen, then other steps are needed but chances are chambering will be proper so let's stop here for now. Be sure to lube your cases for sizing if this has not been mentioned.

The above just says the same thing that has been said previously but perhaps in a slightly different manner. It has probably become apparent that there are different ways to say the same thing. Everyone has their own way for explanations and eventually it all comes together and makes sense.

The above just says the same thing that has been said previously but perhaps in a slightly different manner. It has probably become apparent that there are different ways to say the same thing. Everyone has their own way for explanations and eventually it all comes together and makes sense.

Last edited:

Sorry should have been clearer. I'm not completely clear what specific part you don't understand so I'll explain it a little more. Adjusting the die per instructions did not do that to my cases because I was able to size and fire them twice with no visibly noticeable issue. How ever after the third firing a got some head separation do to repeatedly sizing my cases shorter then needed to optimally fit my chamber . Meaning in this case and "my" comparator. The ideal case size head to datum is 1.619" but when using my standard Redding FL die and a standard shell holder adjusted per instructions. The cases were sized to 1.611 to 1.610 which is .009 shorter then what is optimal for my chamber . That resulted in leaving the .009 space between the head of the case and the bolt face when fired . Repeatedly firing cartridges with that much head clearance can and will result in case stretch and head seperation

I disagree; it is not about suddenly, all at one and without warning. It is about bad habits. Time and time again I say the comparator is not a head space gage and I say the case does not have head space. After that I suggest the reloader should determine the dies ability to return a case to minimum length and I always suggest the reloader determine the deck height of the shell holder. My shell holders have a deck height of .125”. If a reloader measure the length of the case from the shoulder to the case head before firing and again after firing the length of the chamber from the shoulder to the bolt face would be know. Why stick the case in a comparator that is notoriously in error?Adjusting the die per instructions did not do that to my cases because I was able to size and fire them twice with no visibly noticeable issue.

I suggest a reloader purchase standards if they are going to use a a comparator for absolute measurements that can be compared to SAAMI specifications.

F. Guffey

When I first started reloading, I thought all chambers were all cut the same exact size per caliber, store bought bullets would work in every firearm. So reloading instructions would work just right. Then from reading, found some chambers could be loose, tight , long & short throated. Then the fun starts, adjusting the die to adjust to your chamber. Trial & error, once you realize things aren't the same, making these adjustments isn't that complicated. Paying attention to your fired brass, case prep, powder, charge , bullet & seating depth, just to get they 5 shot one hole group. Piece of cake. After 25+ years still trying different things. Just love the sport.

Guffey , if you were to read ALL of my post as a whole . As I hope the OP is . You would see I never indicated anything happened suddenly . I repeatedly used the phrase repeated firing in regards to head separation . All I was trying to say in that last post was sizing your cases once from a once fired cases as per die instructions will not likely result in case separation on your first reload and that's all the die manufacture cares about . Although not 100% of the time . Generally It's the repeated firing of those short cases that give you case separation . Based on all I've wrote in this thread , I thought that would have been clear especially to an experienced reloader .

I also made it quite clear a comparator is ONLY to compare fire formed cases to sized cases .

Why do you feel the comparator will not tell you the same thing ? When wanting to know the specific measurement of the case . I measure a go gauge and see how much the comparator is off , if at all . I then add or subtract the difference to the measurement of the case to get the actual size . That's not needed in the context we are talk in this thread though .

Will you please post a link or picture of the tool you use to make those measurements ?? A drawing would be fine . I and I'm sure others would truly appreciate knowing a better more exact way to take those measurements .

I also made it quite clear a comparator is ONLY to compare fire formed cases to sized cases .

If a reloader measure the length of the case from the shoulder to the case head before firing and again after firing the length of the chamber from the shoulder to the bolt face would be know.

Why do you feel the comparator will not tell you the same thing ? When wanting to know the specific measurement of the case . I measure a go gauge and see how much the comparator is off , if at all . I then add or subtract the difference to the measurement of the case to get the actual size . That's not needed in the context we are talk in this thread though .

Will you please post a link or picture of the tool you use to make those measurements ?? A drawing would be fine . I and I'm sure others would truly appreciate knowing a better more exact way to take those measurements .

Last edited:

603Country

New member

Just remember what Mr Guffey said..."size the case to fit the chamber". That's the objective, and what I try to do.

I also made it quite clear a comparator is ONLY to compare fire formed cases to sized cases.

I thought I made it quite clean I did not agree and you were wrong. I suggest measuring the length of the case from the shoulder/datum to the case head on a minimum length/full length sized new, over the counter ammo first, then fire. And then; measure the length of the case from the shoulder to the case head of the fired case.

Like magic, the reloader is measuring the effect the chamber had on the case when fired. With the minimum amount of information gained from measuring before and again after the reloader knows the length of the chamber and clearance. I off set the length of the chamber with the length of the case when measuring the case length from the shoulder to the case head.

My favorite cases are cases that will not allow the bolt to close because they are too long from the shoulder to the case head. A case that is too long from the shoulder to the case head saves me a trip to the firing range, with a case that is too long I do not find it necessary to fire form (I am a case former, I form first then fire).

And then there is that part about assumed, you assumed the clearance was between the bolt face and case head. If the clearance was between the case head and bolt face you stretched the case .009” between the case head and case body the first time you fired it. And then moving ahead; if you full length sized the case and fired it again the casa stretched .009” again. Then there is that part about bumping, I have said my shoulders do not move, for me that makes it most difficult to ‘bump’ the shoulder.

I have fired cases that were .127” shorter than the chamber from the shoulder to the bolt face than the case from the shoulder to the case head; when fired the shoulder of the case did not move and we all know the case should have ripped apart between the case head and case body.

When bump sizing and the illusion the shoulder moves the .009” stretch between the case head and case body would compress/crush; if the shoulder was bumped back.

F. Guffey

I measure a go gauge and see how much the comparator is off, if at all.

Again and again etc., I do not use datum’s with case friendly datums, there is no way the comparator can be correct if the hole has a radius.

What did you use when measuring the go-gage? Did you assume it was correct or did you use a datum with a radius?

F. Guffey

I thought I made it quite clean I did not agree and you were wrong. I suggest measuring the length of the case from the shoulder/datum to the case head on a minimum length/full length sized new, over the counter ammo first, then fire. And then; measure the length of the case from the shoulder to the case head of the fired case.

Like magic, the reloader is measuring the effect the chamber had on the case when fired. With the minimum amount of information gained from measuring before and again after the reloader knows the length of the chamber and clearance.

I'm confused , Why a factory new round and not just a reload round you sized .009 short from datum to head ?

And then there is that part about assumed, you assumed the clearance was between the bolt face and case head. If the clearance was between the case head and bolt face you stretched the case .009” between the case head and case body the first time you fired it. And then moving ahead; if you full length sized the case and fired it again the case stretched .009” again. Then there is that part about bumping, I have said my shoulders do not move, for me that makes it most difficult to ‘bump’ the shoulder.

You call it assuming , I call it deductive reasoning . If the cases sized .009 short were not the cause of the head separation . Then sizing them .009 longer would not have eliminated the problem . It how ever did completely eliminate my case head separation issue in this rifle with some cases being loaded 10+ times .

When bump sizing and the illusion the shoulder moves the .009” stretch between the case head and case body would compress/crush; if the shoulder was bumped back.

I know you like saying this . Would you be will to explain in detail what you mean ? If an object is in one place and it then appears in another , it moved . If should not matter how it got from point A to point B . It could have been kicked , dropped , pushed , bumped , extruded . Regardless it is no longer in the same place . You don't have to say how the car got from the drive way to the curb . You can just say it moved . Sure technically it was pushed and or rolled , maybe hit and slid there . Regardless it still moved . So if a cases shoulder is 1.633 before sizing and after sizing it is 1.624 . The shoulder moved . It appears to me you are trying to be to technically clever in your definition .

Last edited: