I think that is exactly what I will do. If I find one of the loads I provided for him that he is satisfied with, I will just set the die and go. Knowing there will be variances because of the bullet choice.Brother loaded up some 5.56 varmint loads. We wanted an expanding bullet. There is a Nosler Varmint Ballistic Tip of approx 60+ grains.

Benchmark (being a step faster than Varget) gave excellent accuracy and velocity.

FWIW, For 5.56 ,with 1 on 9 twist 16 in bbl, Varget is my go-to for 69 gr bullets.

Point,you have good,useful powder in Benchmark. IMO, its a step "quick" for the 308 168 gr.

---------------------------------------------------------------------------------

a thought just occured to me,and it piggy backs on what cdoc said above

You are wanting to not waste time and components .

I get it you are trying to do a good,meticulous job for your buddy. And you are learning.

This seating depth thing ordinarily begins by establishing the LOA where the bullet contacts the rifling. That is the start point. Then our handloader might incrementally seat deeper to find as ideal distance off the lands for that rifle.

The "Jump"

We (maybe) skipped the step of finding the lands. Thats OK. With the AR-10, you have a magazine length. 2.800 is book max loa because it works through the magazine. Its got nothing to do with contacting the rifling.

I'd bet,at 2.800, the ogive of the 168 gr MK is already an appropriate distance off the lands. Thats an assumption on my part,it won't hurt to verify. But I'm pretty confident.

If you want to save components, I suggest you just load to 2.800 and go shooting.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seating Depth Frustration

- Thread starter USAF Ret

- Start date

Everything made by man has a range of tolerances, a certain +/- amount inside of which it will work, and outside of which, it may not.

Absolute, precise uniformity of ammunition isn't a bad thing, but its only a useful thing IF you, and your rifle, get some actual benefit from it.

Actually, the listed max overall length does have something to do with contacting the rifling. It ensures that standard bullets DO NOT contact the rifling when loaded to that length. Its got nothing to do with setting the distance OFF the rifling, only that there is some.

Industry standards are just that, industry standards, set to ensure that the ammo fits and functions safely in every gun chambered for it (that also meets industry standards).

Those measurements might be the "sweet spot" for a given rifle and load, or they might not be, all they are is a place where it should work, safely.

Absolute, precise uniformity of ammunition isn't a bad thing, but its only a useful thing IF you, and your rifle, get some actual benefit from it.

With the AR-10, you have a magazine length. 2.800 is book max loa because it works through the magazine. Its got nothing to do with contacting the rifling.

Actually, the listed max overall length does have something to do with contacting the rifling. It ensures that standard bullets DO NOT contact the rifling when loaded to that length. Its got nothing to do with setting the distance OFF the rifling, only that there is some.

Industry standards are just that, industry standards, set to ensure that the ammo fits and functions safely in every gun chambered for it (that also meets industry standards).

Those measurements might be the "sweet spot" for a given rifle and load, or they might not be, all they are is a place where it should work, safely.

Sierra recommends 2.800 for that bullet, so you should be good to go with it.

It should be alright to use 2.8". I wouldn't say sierra recommends that. It is just what they had when they did the test.

Actually, the listed max overall length does have something to do with contacting the rifling. It ensures that standard bullets DO NOT contact the rifling when loaded to that length. Its got nothing to do with setting the distance OFF the rifling, only that there is some.

Not sure about that. Round nose bullets (not very uncommon) can contact rifling even shorter than max. I had that happen to me a few times.

-TL

Sent from my SM-N960U using Tapatalk

Round nose bullets (not very uncommon) can contact rifling even shorter than max. I had that happen to me a few times.

I would be interested in hearing the details of those times.

Specifics, caliber gun, specific bullet, etc.

Generally speaking the RN or FP slug will be shorter than the pointed one.

Which is not to say it can't happen, so I'm curious about what occured that allowed it to happen....

It is possible if the following conditions are met.I would be interested in hearing the details of those times.

Specifics, caliber gun, specific bullet, etc.

Generally speaking the RN or FP slug will be shorter than the pointed one.

Which is not to say it can't happen, so I'm curious about what occured that allowed it to happen....

1. Leade in the chamber happens within max COAL.

2. Bullet is longer than (COAL - brass length).

What it takes is a less pointy bullet ogive profile. Round nose, flat point, or even, to the very extreme, cylindrical with no ogive.

I don't quite remember the details. But it must one of my milsurp rifles. I switched from a spritzer point bullet to round nose, keeping the same COAL. Bullet jammed to the riflings. I didn't know till I extracted an unfired round. Power was everywhere and I had to push out the stuck bullet with cleaning rod.

Round nose is shorter than spritzer of the same weight. But it doesn't have to be the same weight.

-TL

Sent from my SM-N960U using Tapatalk

I switched from a spritzer point bullet to round nose, keeping the same COAL. Bullet jammed to the riflings.

ok, that explains it, you kept the same COAL. This actually let the shorter RN bullet be seated further out, where the wide portion of the bullet could (and did) jam into the rifling.

When I seat RN slugs instead of pointed ones I don't touch my seating stem. This results in a round with a shorter COAL but keeps the full diameter part of the bullet in the same place, and keeps the same amount of bullet base in the case as well.

Even the same stem setting can't guarantee not hitting rifling. It is just less likely. As long as the leade starts within max COAL, it is always possible.ok, that explains it, you kept the same COAL. This actually let the shorter RN bullet be seated further out, where the wide portion of the bullet could (and did) jam into the rifling.

When I seat RN slugs instead of pointed ones I don't touch my seating stem. This results in a round with a shorter COAL but keeps the full diameter part of the bullet in the same place, and keeps the same amount of bullet base in the case as well.

For each bullet-rifle combination I want to know the COAL that hits to he rifling. I want to enter the bullet jump on GRT. It makes the results more accurate.

-TL

Sent from my SM-N960U using Tapatalk

Even the same stem setting can't guarantee not hitting rifling. It is just less likely. As long as the leade starts within max COAL, it is always possible.

I suppose its possible, if you're using some really odd bullet profile but I don't see how, if your die is set so that "regular" bullets don't hit the rifling I can't see where a shorter fatter slug would.

Unless you're seating swc pistol bullets, the seating stem bears on the bullet well below the tip. I set my dies initially, on a factory round, which produces a round within max COAL and not touching the rifling. This has worked for me loading over 30 different calibers in over 50 years of reloading. I don't see how you would do otherwise and jam a bullet into the rifling, but obviously some people can, and have.

The OP specified he was loading a 168 gr Sierra MK for an AR- !0

I have experience with that bullet used with a pair Badger Barrel originally installed by Armalite in a pair of AR-10 T s and a Kreiger installed replacement barrel,along with my stock DPMS LR 308 L barrel.

No rifling contact loaded to 2.800. I can't prove it,but I'd assume the military 175 gr 7.62 Sniper round would work in an SR-25.

I'd like to think the design folks would spec the reamer to work with relatively standard ammo loaded to mag length without a lot of tail chasing.

Yes,a person might find good reason to load an unusual bullet (like a heavy round nose). Sometimes taking the steps to check is good.

You CAN find 168 gr match ammo.

Within the scope of the OP's question, I do not think there is a problem.

I suggest we recognize where the OP is. He started with 2.800 without finding the lands or having the rifle. Understandable. There is a lot to digest. Loading progressively deeper from 2.800 is IMO, a stroll through the briar patch when he is trying to get ready for a range trip and conserve components.

Side trips to the weeds can be counter productive when following the path will reach the destination.

I have experience with that bullet used with a pair Badger Barrel originally installed by Armalite in a pair of AR-10 T s and a Kreiger installed replacement barrel,along with my stock DPMS LR 308 L barrel.

No rifling contact loaded to 2.800. I can't prove it,but I'd assume the military 175 gr 7.62 Sniper round would work in an SR-25.

I'd like to think the design folks would spec the reamer to work with relatively standard ammo loaded to mag length without a lot of tail chasing.

Yes,a person might find good reason to load an unusual bullet (like a heavy round nose). Sometimes taking the steps to check is good.

You CAN find 168 gr match ammo.

Within the scope of the OP's question, I do not think there is a problem.

I suggest we recognize where the OP is. He started with 2.800 without finding the lands or having the rifle. Understandable. There is a lot to digest. Loading progressively deeper from 2.800 is IMO, a stroll through the briar patch when he is trying to get ready for a range trip and conserve components.

Side trips to the weeds can be counter productive when following the path will reach the destination.

The seater stem contact the ogive at some point. If that point is already in the leade (quite usual for a new chamber), changing to a less pointy ogive will have a good chance to contact the rifling, even with the same stem setting, especially so if the original bullet jump is little. The point is seating under max COAL does not guarantee non-zero bullet jump.I suppose its possible, if you're using some really odd bullet profile but I don't see how, if your die is set so that "regular" bullets don't hit the rifling I can't see where a shorter fatter slug would.

Unless you're seating swc pistol bullets, the seating stem bears on the bullet well below the tip. I set my dies initially, on a factory round, which produces a round within max COAL and not touching the rifling. This has worked for me loading over 30 different calibers in over 50 years of reloading. I don't see how you would do otherwise and jam a bullet into the rifling, but obviously some people can, and have.

-TL

Sent from my SM-N960U using Tapatalk

The point of the ogive where the seating stem contacts it is less than full caliber bullet diameter. Usually at a point quite a bit less than that (and closer to the nose of the bullet).

Normally, any part of the bullet sticking into the bore where the leade begins is substantially less than the diameter which would contact the rifling. So it touches nothing.

I guess the question is what is the difference between where your seating stem contacts the bullet and where on the bullet is the point where it is wide enough to contact the rifling.

What I'm thinking is, that if the point on the bullet where the seating stem contacts it is ahead of the point where the bullet is wide enough to contact the rifling (and I think it usually is) then using the same stem setting that keeps a pointed bullet out of the rifling will do the same for a RN or FP bullet as well.

I wonder if Uncle Nick has one of his wonderful drawings illustrating that?

Normally, any part of the bullet sticking into the bore where the leade begins is substantially less than the diameter which would contact the rifling. So it touches nothing.

I guess the question is what is the difference between where your seating stem contacts the bullet and where on the bullet is the point where it is wide enough to contact the rifling.

What I'm thinking is, that if the point on the bullet where the seating stem contacts it is ahead of the point where the bullet is wide enough to contact the rifling (and I think it usually is) then using the same stem setting that keeps a pointed bullet out of the rifling will do the same for a RN or FP bullet as well.

I wonder if Uncle Nick has one of his wonderful drawings illustrating that?

I think for my intents and purposes, I am probably getting a bit too anal on things. My buddy was happy with results, so I am good. Even with the variation, he had a couple of groups just a little over MOA with a PSA AR-10.

I did measure some Nosler ABLR factory seconds and those were no more than .002 variance in ogive. All about the bullets.

I did measure some Nosler ABLR factory seconds and those were no more than .002 variance in ogive. All about the bullets.

Exactly,

Keep shooting and practicing.

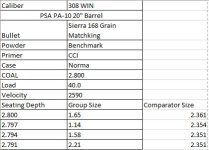

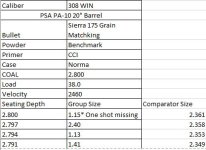

Looks like the 2.354 on the 168s and 2.353 on the 175s. You can seat them deeper and see if you hit a node usually you will see groups the same moa in a node area for example 2.353, 2.350 2.347 should group close together then you know you hit a great seating depth. And you shouldn’t have to change it much after that.

I was lucky and found my node in 30-06 at 2.717 for 168s and haven’t touched it since .

If you find something that works! write that recipe down notice I used your comparator numbers vs OAL

Keep shooting and practicing.

Looks like the 2.354 on the 168s and 2.353 on the 175s. You can seat them deeper and see if you hit a node usually you will see groups the same moa in a node area for example 2.353, 2.350 2.347 should group close together then you know you hit a great seating depth. And you shouldn’t have to change it much after that.

I was lucky and found my node in 30-06 at 2.717 for 168s and haven’t touched it since .

If you find something that works! write that recipe down notice I used your comparator numbers vs OAL

Last edited: