Made it out to the range.

Gun shot well! I put about 12 rounds of magnums through it. Another 12 .38 special +p and the rest regular specials. About 100 rounds in total. All the regular specials were older dirtier shooting 158 grain lead bullets that I've had on hand for a good while.

By 100 rounds, I noticed a bit of tightness with the cylinder rotation on just one chamber when shooting double action. All other chambers were fine. I noticed it was the same when dry firing, so i guess that would be my only complaint.

Other people at the range commented on how nice it was and what a great trigger it had. Everyone thought I got some great deal. I think i did well enough.

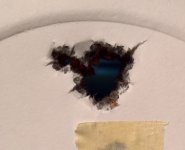

Attached is a 12 shot single action group i shot standing and unsupported at 7 yards.

Would any of you mind posting a link to feeler gauges for sale online that would work for measuring the gap? Id just like some examples, then maybe I'll pick some up at the hardware store.

Also wanted to mention again, I didn't see any wear marks on the front of the cylinder at the two chambers that appear to make contact with the top of the forcing cone. With the cylinder locked in place, I can pull it backwards and there is then a very slight visible gap on the two chambers that otherwise appear to make contact with the forcing cone, with the cylinder pushed forward, they appear to make contact to the same degree as when I'm just clocking and releasing the hammer like normal. The other 4 chambers don't appear to make contact even if I push the cylinder forward.