The basic problem of case stretch can be cured with case lubrication. Breaking the friction between case and chamber walls will prevent case head separations. The Lee Enfield, being a rear locking mechanisms, stretches significantly more than a front locking mechanism. Also, the distance between base and shoulder is not standardized, and that significantly aggravates the problem of case sidewall stretching. The Lee Enfield is particulary bad in this respect.

In this thread, Parashooter shows how by lubricating his 303 British cases, he was able to extend case life and prevent case head separations. :

Cases and Enfields and lube - Oh my!

http://www.milsurps.com/showthread.php?t=11182&

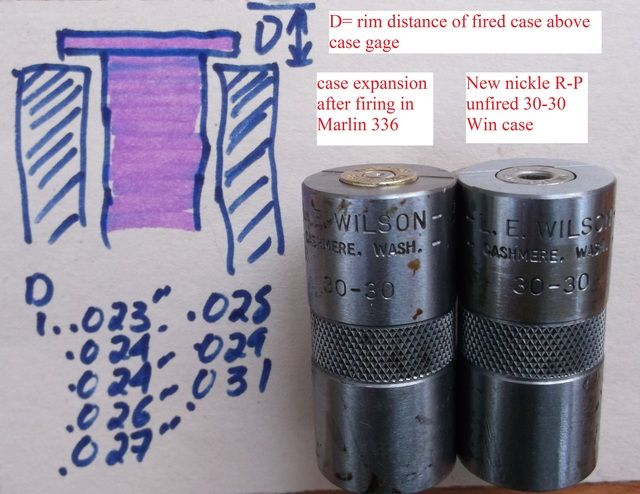

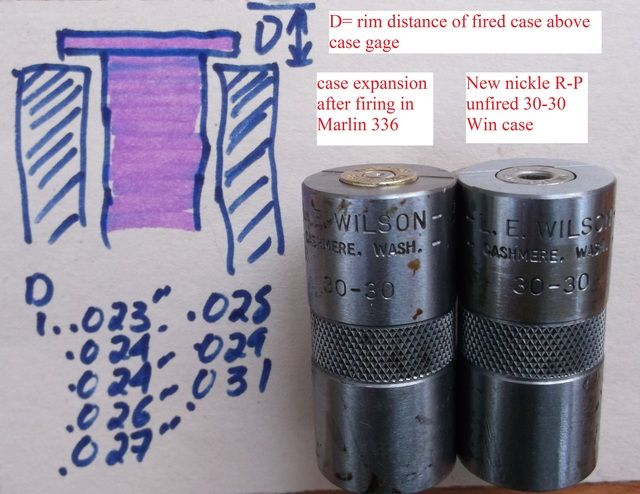

My Marlin 336 in 30-30 has a huge chamber, the shoulders of the case are blown forward an extraordinary amount. I measured the amount of shoulder movement of eight fired cases, using my LE Wilson case gages. The average distance the shoulder moved was 0.0325” from the Go of the gage.

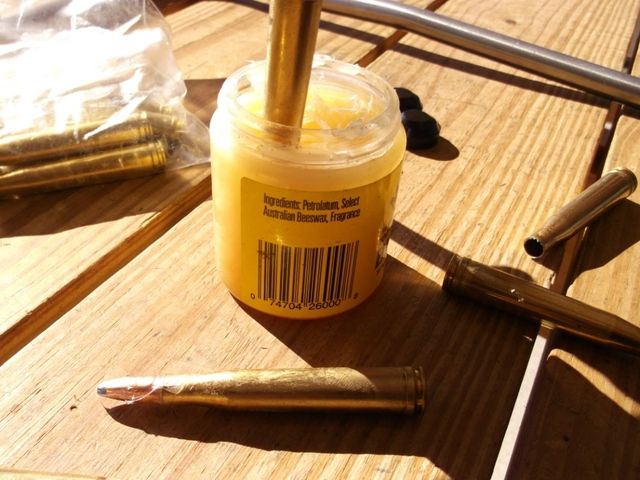

If I had not lubricated the new cases prior to firing, it is very possible I would have experienced case head separations on the first firing. Now there are a number of Old Economy Steve’s who are so financially well off, with their defined benefit pensions, Social Security, Medicare and Medicaid, that tossing away money is not an issue. However, I am cheap by nature and want to get the most value out of my cash, and therefore I want to achieve the maximum possible case life. So I lubricate all my rimmed and belted magazine cases on first firing, so the sidewalls are not excessively stretched.

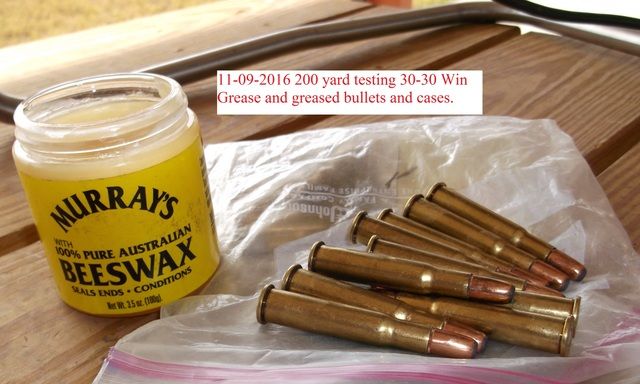

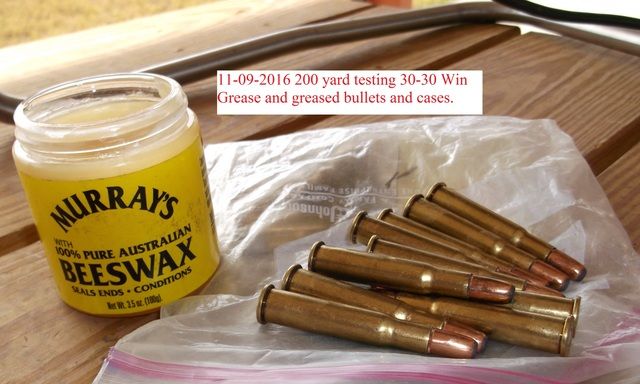

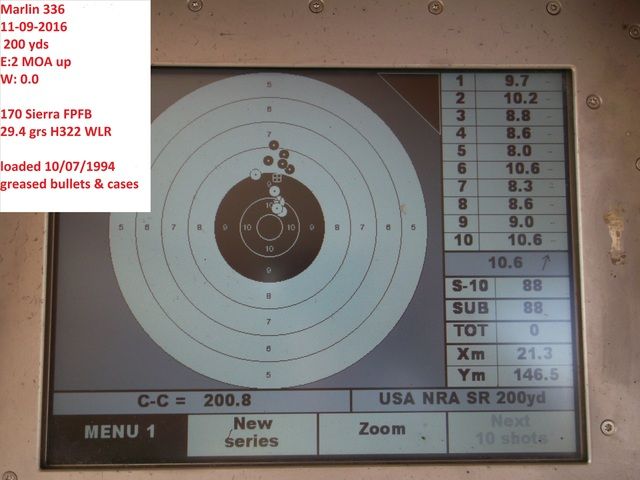

Here, at CMP Talladega, I shot my Marlin 336 at 200 yards, and since the cases were brand new, I lubricated the bullets and cases.

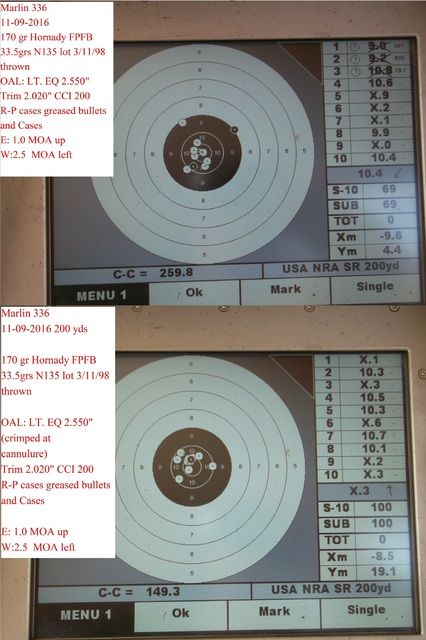

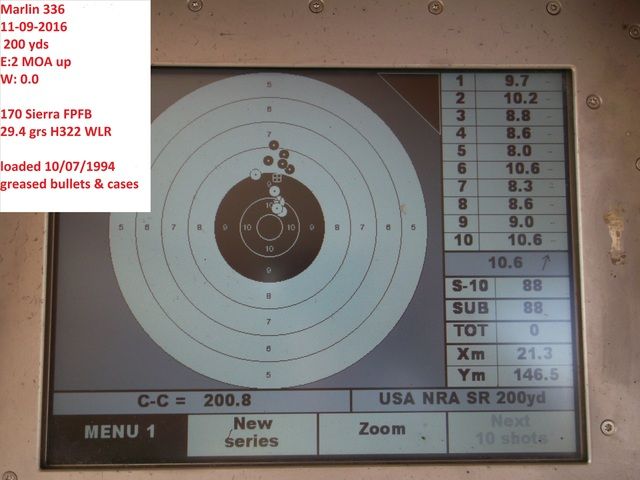

They shot well, for a lever action. This is my best load:

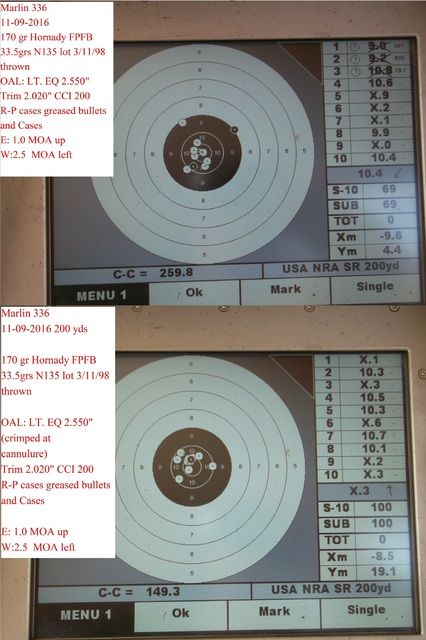

This is an older load, still a good one:

For this 30-30, I plan to continue to lubricate the case before firing, because the action is such a stretchy one. I have done the same for my 303 Brit, but I hardly ever fire those military cartridges anymore.

In this thread, Parashooter shows how by lubricating his 303 British cases, he was able to extend case life and prevent case head separations. :

Cases and Enfields and lube - Oh my!

http://www.milsurps.com/showthread.php?t=11182&

My Marlin 336 in 30-30 has a huge chamber, the shoulders of the case are blown forward an extraordinary amount. I measured the amount of shoulder movement of eight fired cases, using my LE Wilson case gages. The average distance the shoulder moved was 0.0325” from the Go of the gage.

If I had not lubricated the new cases prior to firing, it is very possible I would have experienced case head separations on the first firing. Now there are a number of Old Economy Steve’s who are so financially well off, with their defined benefit pensions, Social Security, Medicare and Medicaid, that tossing away money is not an issue. However, I am cheap by nature and want to get the most value out of my cash, and therefore I want to achieve the maximum possible case life. So I lubricate all my rimmed and belted magazine cases on first firing, so the sidewalls are not excessively stretched.

Here, at CMP Talladega, I shot my Marlin 336 at 200 yards, and since the cases were brand new, I lubricated the bullets and cases.

They shot well, for a lever action. This is my best load:

This is an older load, still a good one:

For this 30-30, I plan to continue to lubricate the case before firing, because the action is such a stretchy one. I have done the same for my 303 Brit, but I hardly ever fire those military cartridges anymore.