There are several types of bluing.

Cold blue, the kind that comes as a liquid, creme, or paste, does not last and has little resistance to wear. Some people who use it brag about how good it looks, but later find that it has partly worn off and the gun looks a lot worse than it did.

Caustic salt blue, aka "tank blue", is the kind used by professionals. It involves the use of highly dangerous chemicals that can inflict severe burns and eat through clothing, floor coverings and the like, so it is not a home project. At one time, almost every gunsmith did tank bluing, but stringent regulations have discouraged most of them from continuing to offer that service. Today, most gunsmiths send bluing jobs to one of the shops that specialize in bluing.

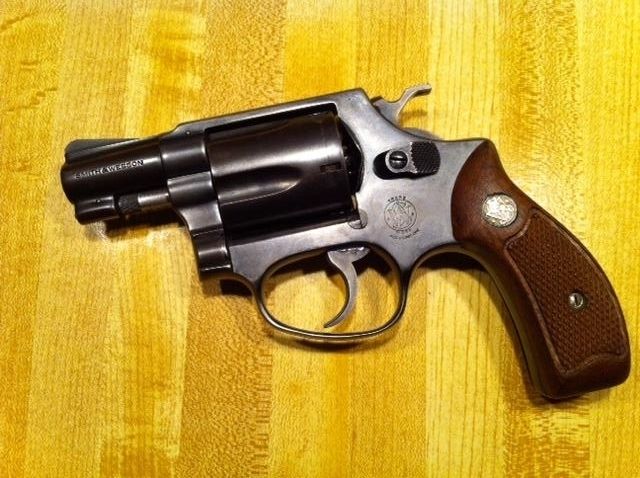

Carbonia blue was/is used by factories, like S&W and Colt; it is very durable and produces a blue-black finish that looks great if preceded by high quality polishing. But the process requires heating in a gas furnace and is part of the heat treatment process, in effect preventing it from being used for re-bluing. In appearance, it is not enough different from caustic bluing to be readily apparent, even to the trained eye. It is not a DIY process.

Charcoal blue was used by the old factories, like Colt and Remington in the 1850's and 1860's. It involves heating the work in a bed of charcoal in an iron box in a furnace. It produces a deep blue-black look, again depending partly on the polish. It can be done at home with a suitable heat source (coal furnace, for example) but is complex and the work can be ruined if not done carefully.

Oil bluing, or oil blackening, was used by Springfield Armory and some others c. 1900. It also was part of the heat treatment and involves heating the work almost red hot; it cannot be restored and guns requiring refinish were rust blued. It tends to flake off and many old Krag-Jorgensen rifles show that flaking on the receiver, sideplate, or magazine door. It also is not a DIY project and trying to use it could ruin the gun or make it dangerous.

Rust bluing is an old process. Bluing itself is an oxidation process, essentially a refined rust. Rust bluing is fairly easy, requiring little in the way of equipment except a tank in which water can be kept boiling and which is large enough for the work. But it is tedious and time-consuming; it is easy to make a mistake, requiring starting all over. The finish is a soft blue, usually seen on European guns, like World War I era Luger pistols.

Paint, of one kind or another, is also an old process, and was used for military weapons as early as the 1850's. It is durable, easy to apply and gives good protection. Modern paints are baked on and available in a variety of colors, including a simulation of bluing. For a practical firearm, military or sporting, it does the job, but eliminates any collector value.

As for collector value, any rebluing will reduce that value. It is possible, though very difficult, to apply any re-finish that will appear original and pass inspection by an experienced collector. Rebluing or refinishing should really not be done to any gun of collector interest unless the finish is so poor that, in effect, anything will be an improvement, and in that case, rebluing will do little to improve the appearance. In most cases, the collector will prefer an original finish, even if well worn, to a refinish.

HTH

Jim