You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Questions about 10mm round

- Thread starter Topthis

- Start date

Koda...it's the Rock Island 1911 in 10mm. I have become a huge 1911 fan in recent years and own mostly custom 1911's. I have decided to convert over to 1911 in all of my calibers. I have only seen the Rock Island in the Commander size, all the others are either Long Slide or Full Size and I started to think about the advantages of having a 10mm as a carry, but didn't want to do it if I lost too much velocity...might as well carry a .40.

Evil Monkey

New member

Why do you need 10mm? What a useless cartridge.

Excessive recoil out of a pistol, inferior ballistics from a carbine.

What's the point?

Excessive recoil out of a pistol, inferior ballistics from a carbine.

What's the point?

Can you tell me which model RIA? I'm not seeing one on their website: https://us.armscor.com/products/category/pistols/

excellent cartridge BTW, you dont have to carry full pressure rounds for SD.

excellent cartridge BTW, you dont have to carry full pressure rounds for SD.

Originally posted by Evil Monkey

Why do you need 10mm? What a useless cartridge.

Excessive recoil out of a pistol, inferior ballistics from a carbine.

What's the point?

I guess it depends on how much recoil one considers "excessive". I find the recoil of full-power 10mm ammo like Buffalo Bore or Underwood from my S&W 1076 to be somewhere in between that of my fullsize 1911 with 230gr .45 ACP +P and my S&W K-Frame revolvers with 158gr .357 Magnum, and honestly the recoil is closer to the .45 than the .357.

What you get in return, however, is a cartridge that, depending on the ammunition, can give you ballistics ranging from .40 S&W with the lower end loadings to top-end .357 Magnum/low-end .41 Magnum with full-power loadings in a semi-automatic platform the same size as a .45 ACP. IMHO, a very convincing argument could be made for the 10mm as the "do-all" semi-automatic cartridge, particularly for a handloader.

Sorry Koda, don't know the Model, but if you go to the 1911 forum, there are some threads on them.

I also find the recoil very easily manageable, having been shooting 10mm through the Glock 20sf. Have found the 10mm to be a very interesting round. With light loads, it has the same velocity and pretty much makes it a manageable .40. "Packin' powder", I have seen some charts that claim upwards to 2000fps...not sure if that's for a semiauto, but I'd also be curious what kind of semi can take that kind of pressure on a regular basis? Regardless...that is a HUGE range and in my opinion, makes this a very effective and respectable caliber.

I also find the recoil very easily manageable, having been shooting 10mm through the Glock 20sf. Have found the 10mm to be a very interesting round. With light loads, it has the same velocity and pretty much makes it a manageable .40. "Packin' powder", I have seen some charts that claim upwards to 2000fps...not sure if that's for a semiauto, but I'd also be curious what kind of semi can take that kind of pressure on a regular basis? Regardless...that is a HUGE range and in my opinion, makes this a very effective and respectable caliber.

Armed_Chicagoan

New member

Here's a handy chart: http://www.ballisticsbytheinch.com/10mm.html

I dont think RIA makes a commander sized 10mm, I think you'll find any, if at all, are custom and pretty spendy.

Certainly not out of a commander size 1911 let along a govt size. The original 10mm was designed as a 200g bullet at 1200 fps. Take a look at the link Armed_Chicagoan shared theres nothing even close to 2000fps.... I'd reconsider the source of what you've readI have seen some charts that claim upwards to 2000fps...not sure if that's for a semiauto, but I'd also be curious what kind of semi can take that kind of pressure on a regular basis?

Chrono Data

Well topthis, I have a Glock 20 (4.6" bbl) and a Glock 29 (3.77" bbl) and lots of chrono data with them. I don't have a 5" bbl, but I think it will still give some indication. . .

HPR (a boutique brand) 180g FMJ: 1164 & 1202 fps respectively (38 fps or about 3% difference).

HPR 180g JHP: 1188 & 1197 fps respectively (9 fps or about 0.7% difference)

HPR 200g JHP: 1048 & 1054 fps respectively (6 fps or about 0.6% difference)

Federal HydraShok 180g JHP: 983 & 988 fps respectively (5 fps or 0.5% difference)

Medium power handloaded round; 180g PFP, 8.8g AA5: 1046 & 1063 fps respectively (17 fps or 1.6 % difference)

Medium-strong power handloaded round; 165g GDHP, 9.0g Power Pistol: 1244 & 1280 fps respectively (36 fps or 2.9% difference)

So as you can see, there isn't much difference. The larger Glock has a longer sight radius and handles better. But it doesn't deliver significantly more velocity. I was a little surprised by this myself.

Hope that helps a little.

Well topthis, I have a Glock 20 (4.6" bbl) and a Glock 29 (3.77" bbl) and lots of chrono data with them. I don't have a 5" bbl, but I think it will still give some indication. . .

HPR (a boutique brand) 180g FMJ: 1164 & 1202 fps respectively (38 fps or about 3% difference).

HPR 180g JHP: 1188 & 1197 fps respectively (9 fps or about 0.7% difference)

HPR 200g JHP: 1048 & 1054 fps respectively (6 fps or about 0.6% difference)

Federal HydraShok 180g JHP: 983 & 988 fps respectively (5 fps or 0.5% difference)

Medium power handloaded round; 180g PFP, 8.8g AA5: 1046 & 1063 fps respectively (17 fps or 1.6 % difference)

Medium-strong power handloaded round; 165g GDHP, 9.0g Power Pistol: 1244 & 1280 fps respectively (36 fps or 2.9% difference)

So as you can see, there isn't much difference. The larger Glock has a longer sight radius and handles better. But it doesn't deliver significantly more velocity. I was a little surprised by this myself.

Hope that helps a little.

If you buy the handloading software program Quickload, it will calculate the velocity of different barrel lengths.

I have put a lot of effort into making a more powerful carry handgun.

The length of the barrel does not matter.

Certainly 40sw vs 10mm does not matter, even though 40sw is CAPABLE of more with it's small primer pocket.

The first limitation is case support.

With an aftermarket barrel with a feed ramp no deeper than the case web is thick, case support is no longer the problem.

The problem is then recoil.

About half the momentum from the projectile and and gas goes into the slide motion relative to the frame. The other half moves the frame and arm. If the recoil spring is not high enough force to store that much energy, then the slide hammers the frame. A little is ok, but a lot is not.

If I put in springs with such high force that I am the only man I know with the grip required to chamber a round, I can still handload 10mm, 40sw, 45acp, 9x19mm or even 380 too hot for those springs. The cases fly a long way and the slide hammer the frame. That is not good for the gun OR my hand.

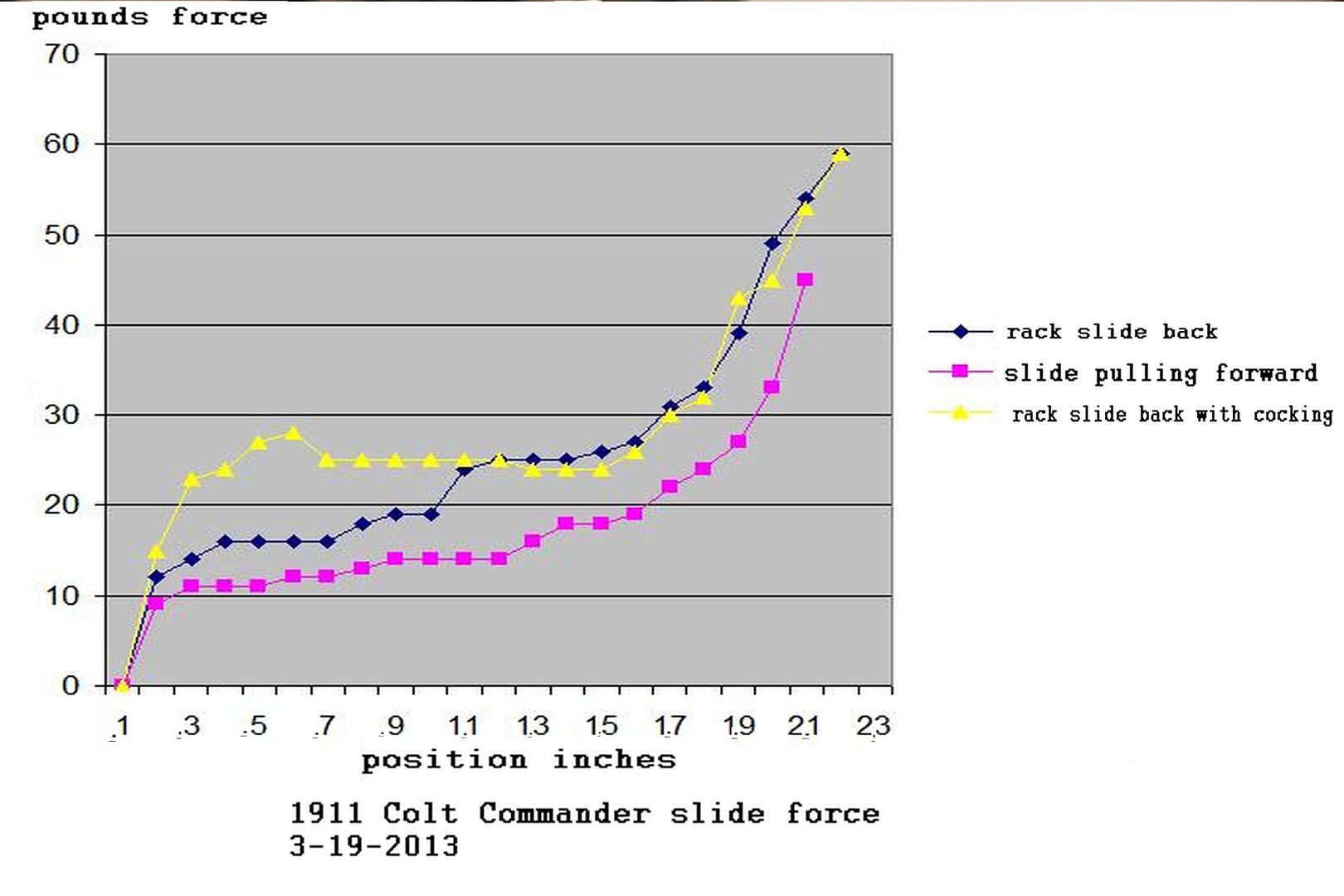

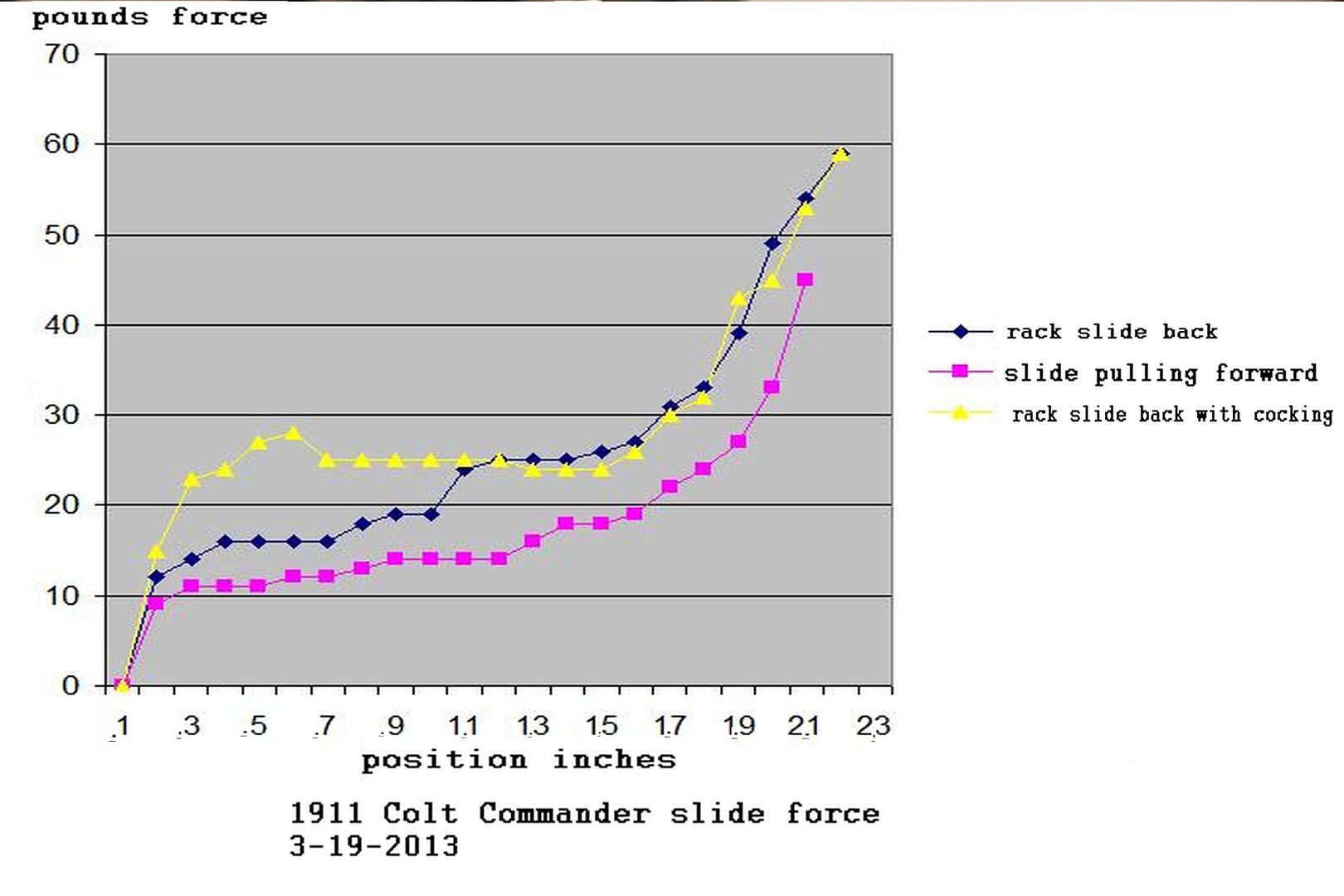

Here is a plot I made [with a Wagner force gauge and an X-Y mill table] of my highly modified 1911 recoil spring [and hammer spring sometimes].

I have put a lot of effort into making a more powerful carry handgun.

The length of the barrel does not matter.

Certainly 40sw vs 10mm does not matter, even though 40sw is CAPABLE of more with it's small primer pocket.

The first limitation is case support.

With an aftermarket barrel with a feed ramp no deeper than the case web is thick, case support is no longer the problem.

The problem is then recoil.

About half the momentum from the projectile and and gas goes into the slide motion relative to the frame. The other half moves the frame and arm. If the recoil spring is not high enough force to store that much energy, then the slide hammers the frame. A little is ok, but a lot is not.

If I put in springs with such high force that I am the only man I know with the grip required to chamber a round, I can still handload 10mm, 40sw, 45acp, 9x19mm or even 380 too hot for those springs. The cases fly a long way and the slide hammer the frame. That is not good for the gun OR my hand.

Here is a plot I made [with a Wagner force gauge and an X-Y mill table] of my highly modified 1911 recoil spring [and hammer spring sometimes].

I am of the thought that there are better choices than a 10mm. I do like the cartridge but really it's still a service class handgun round that in terms of ability, can't do anything the .40 or .45 isn't already doing.

I'm not saying it's worse, but I am saying that for the price and relative rarity of the cartridge, what exactly is it giving you that is worthwhile? Anything someone would use a 10mm for can just as effectively be done with a .40 or .45.

I'm not saying it's worse, but I am saying that for the price and relative rarity of the cartridge, what exactly is it giving you that is worthwhile? Anything someone would use a 10mm for can just as effectively be done with a .40 or .45.

Evil Monkey

New member

I started to think about the advantages of having a 10mm as a carry,

If you wanted 10mm for fun, cool. But as a defense round, there's nothing the 10mm can do out of a pistol that 9mm, 40, or 45 defense loads cant do.

Uncle Malice

New member

there's nothing the 10mm can do out of a pistol that 9mm, 40, or 45 defense loads cant do.

What?

The advantage of the 10mm is range, not "power", per se.

The FBI determined that for service use, you didn't get much by driving a .40", 180gr bullet any faster than 950fps, and so, the .40 S&W was born.

I like the 10mm a lot, for its versatility, but for self-defense or service use, you don't get much in return for the recoil and muzzle blast of full-power loads.

For hiking in the woods, 200@1200 would be a comfort whether the varmints were of the two- or four-legged variety.

The FBI determined that for service use, you didn't get much by driving a .40", 180gr bullet any faster than 950fps, and so, the .40 S&W was born.

I like the 10mm a lot, for its versatility, but for self-defense or service use, you don't get much in return for the recoil and muzzle blast of full-power loads.

For hiking in the woods, 200@1200 would be a comfort whether the varmints were of the two- or four-legged variety.

Played a lot with 10mm and .40 Super 1911s. I am not sure I would want to even try a 1911 in commander length with a 10mm and full power ammo. The 10mm is near the edge of the envelope for the 1911 in terms of spring rate, slide velocity. When you reduce the barrel length, the slide velocity will increase and the average pressure in the barrel will go up. The .40 Super very well might be over the edge as it is very hard to balance slide velocity and spring rate with feed reliability, and mine is a 6" barrel.

OTOH, you could go to some reduced power loads in a commander and likely be perfectly fine with it.

I shot a cow elk with my 10mm 1911 at 80 yards...the bullet expanded nicely, but it did exit.

OTOH, you could go to some reduced power loads in a commander and likely be perfectly fine with it.

I shot a cow elk with my 10mm 1911 at 80 yards...the bullet expanded nicely, but it did exit.

Excessive recoil out of a pistol, inferior ballistics from a carbine.

What's the point?

I get 1300 fps with 200 gr DoubleTap ammo from my G-20. With less felt recoil than 45 ACP from my 1911's.

Just for reference my 3" 44 mag revolver is 3/4 lb heavier, 1" longer and only manages 1150 fps with 240 gr ammo from the snub barrel. That is the point.

as a defense round, there's nothing the 10mm can do out of a pistol that 9mm, 40, or 45 defense loads cant do.

As a defensive round against human threats, probably true enough. But some of us want a handgun that is capable of handling threats larger and tougher than humans. The 10mm (properly loaded) is capable of true magnum revolver ballistics from a smaller more compact package with nearly 3X the ammo capacity. At least with the Glock.

I'm a 10mm fan. But will tell any potential purchaser that it is not needed by most people. But if you want to go to the trouble, it is a niche round that delivers.

FWIW, I'd stay away from the RIA in 10mm. The Glock and S&W 1006 series are the only 2 platforms that have proven to be reliable long term with 10mm. Even the more expensive 1911's have been hit or miss with the round. Some work, some don't.