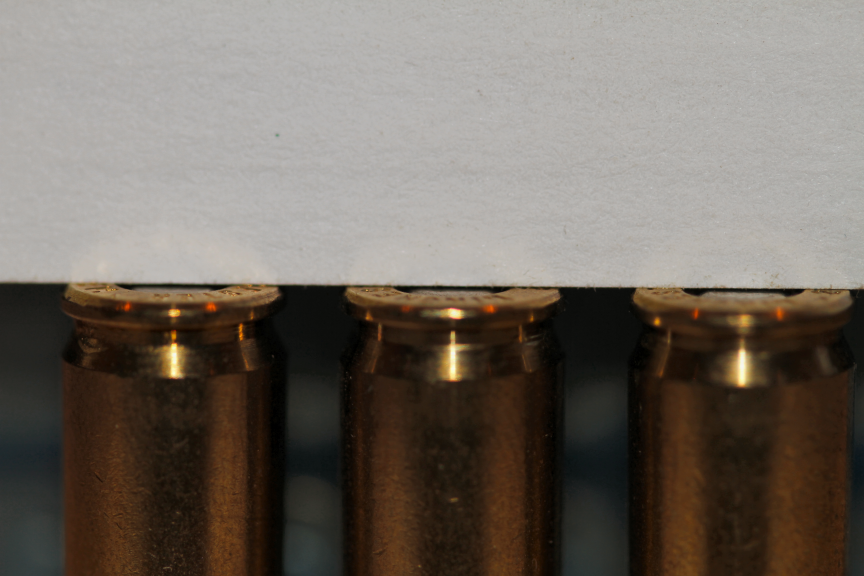

Going solely on the images you supplied, I think several have correctly diagnosed your failure-to-fire problem. You haven't seated the primers deep enough in the pocket. In the second image, I would swear you can see a good portion of the side of the primer which you should not be able to see at that angle, or any angle for that matter. If you still have that case intact, place a straight edge across the base and see what you find.

The first image has good focus on your glove, but the primer is so out of focus as to make that image useless for analysis.

The first image has good focus on your glove, but the primer is so out of focus as to make that image useless for analysis.