It was sold in metal cans until plastic became more economical. Tests done

(don't do this at home; the tests were controlled) putting cans of smokeless powder on open flames always resulted in the gas opening the cans at the seam and the powder flaring off. Only black powder made a bomb. In a heavy metal container, if it is the explosion-proof type, its lid will open before pressure reaches bursting levels.

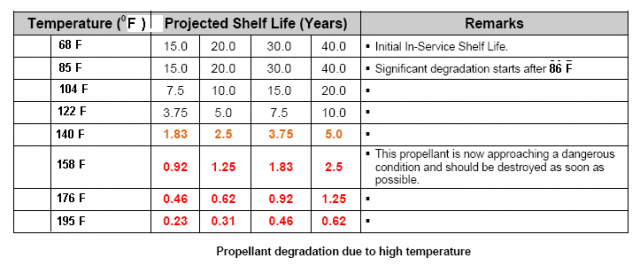

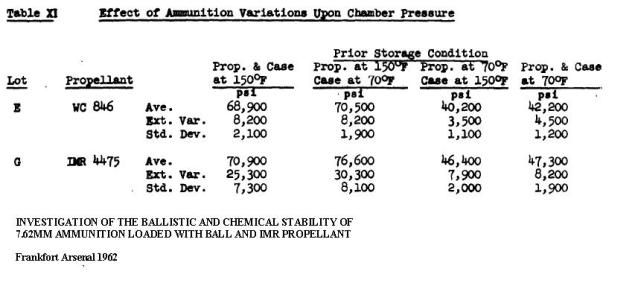

As near as I can tell, if you keep powder bone dry in a freezer it will generally outlive you and your grandchildren. The warmer it gets, the faster it deteriorates. There are some military charts you can find, but IIRC, double base spherical powder can lose deterrents or stabilizer or both after about 18 months at 140°F. If we assume the breakdown rate doubles every 18°F, then the 20 year life the military gives it in stockpiles would occur at about 73°F. It would follow you would get 10 years at 91°F and 5 years at 109°F. Single-base stick powders last about 2¼ times longer, so 45, 22½, and 11¼ years at those three temperatures. And mind you, that would be 24 hours a day at those temperatures. Nights are normally cooler. The military uses munitions bunkers that are pretty massive and are recessed into the ground, so I doubt they see much temperature swing.

There are compound breakdown energy threshold problems with that simple 18°F doubling model, but it's probably reasonable to keep an extra close eye on powders nearing those ages if it kept at those temperatures.

There is another problem that the military knows their powder is fresh when they buy it, but you don't. If a lot of bulk powder does not fall within the burn rate limits set by the distributor for the canister grade version sold to handloaders, the powder company will blend the new bulk lot with older, held back bulk lots that turned out to burn faster or slower than usual, in order to bring the net burn rate into canister grade tolerance. This is done because handloaders work with recipes in manuals. Ammunition factories own pressure test equipment and use it to adjust the bulk grade powder charge to compensate for burn rate error in a particular lot, but that's more change than load manual practices can be counted on to cover.

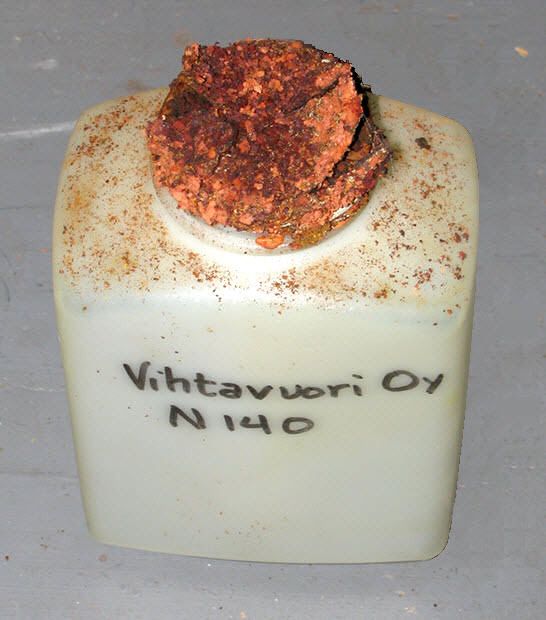

So, without knowing whether your lot needed blending or not, and, if it did, how old the lot blended in was, you don't know how much life it has compared to fresh bulk powder like the military normally uses. There was a recall by Vihtavuori of some N140 that was breaking down prematurely (see what fumes from a sample I had did to the lid of the container after about 10 years; the powder was a solid mass inside). Around 2000 there was a lot of IMR4350 that was going bad on people after just three to five years. So this stuff happens occasionally, making ammo for long term storage from canister grade powders an unreliable proposition. If you intend to do that, I would store some of the unloaded powder with it so you can check its condition before shooting up the loaded stuff.

Learn to recognize deteriorating powder by smell and appearance. Check your powder for smell and by eyeball for red dust before reloading with it as a matter of routine, and watch for pressure signs or velocity increases in loads that used to be fine with that same quantity of that same lot of powder.

A lot of people load ammo to store for Armageddon scenarios, but I recommend they cycle through it steadily by shooting the oldest and then replacing it with fresher loads over time. FIFO (first in, first out) storage.