I wonder what others will think of this type of gas trap?

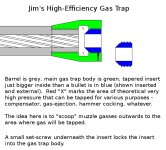

I haven't shown any uses of the gas but there's all kinds of options. I'm planning to alter the gas trap on Maurice to match this design and at that point I should have enough gas for shell ejection and a compensator.

Might actually have enough for hammer cocking if it wasn't for that pesky Hughes Amendment thingie...

I haven't shown any uses of the gas but there's all kinds of options. I'm planning to alter the gas trap on Maurice to match this design and at that point I should have enough gas for shell ejection and a compensator.

Might actually have enough for hammer cocking if it wasn't for that pesky Hughes Amendment thingie...