You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please explain my scale frustration!

- Thread starter Sevens

- Start date

problem solved

you will always have the same problem with the counter balence scales unles you place it dead center every time you will have varience. thats why i dumped my lee lyman and dillon manual scales and went digital. it was like going from rowboat to yacht. you could probably sell that scale on ebay and get a pretty decent digital. a thing to remember to is your powder dispencer is also guilty of having a .01 to .05 gn wgt varience as well each time it cycles.

i have the charge master from rcbs scale / dispencer its pricey but i have no worries

you will always have the same problem with the counter balence scales unles you place it dead center every time you will have varience. thats why i dumped my lee lyman and dillon manual scales and went digital. it was like going from rowboat to yacht. you could probably sell that scale on ebay and get a pretty decent digital. a thing to remember to is your powder dispencer is also guilty of having a .01 to .05 gn wgt varience as well each time it cycles.

i have the charge master from rcbs scale / dispencer its pricey but i have no worries

Yep, it must be something with the little loop or swinging "U" that doesn't fall to exactly the same place every time.

But I'll clear a few things up while I'm here.

First -- the scale doesn't have some monumental "problem." Gotta realize that if I place the brass looking pan in the same exact spot, I get the scale to zero perfectly each and every time. I can take the pan off, run around the man cave, put the pan back on and if it's in the same spot, it will zero.

The scale isn't dirty, the razor edges are good to go, I've never sprayed the scale with anything and I haven't oiled it, bent anything or fouled it up. I've been using it for a good while and I've loaded about 3,450 rounds (all single stage!) since Christmas, checking my Lyman 55 with this scale.

There is no monstrous problem with the scale... I just couldn't figure out why if all the weight in the pan is hanging from that loop, it should matter in any way how the pan was placed on the scale.

I like the monofilament flishing line idea. I'd probably go nuts trying to tie a little knot and make a loop of that size...

And for the folks who are looking WAY too closely at the linked picture and not reading the TEXT very well, that's a Gunblast photo that I linked just to show you the model/brand of my scale. It's a picture for reference. That's not my scale, not my bench and I don't have it adjusted like you see in the photo. I didn't even take that photo... I found it in a quick web search just so you could see the scale that I'm talking about.

But I'll clear a few things up while I'm here.

First -- the scale doesn't have some monumental "problem." Gotta realize that if I place the brass looking pan in the same exact spot, I get the scale to zero perfectly each and every time. I can take the pan off, run around the man cave, put the pan back on and if it's in the same spot, it will zero.

The scale isn't dirty, the razor edges are good to go, I've never sprayed the scale with anything and I haven't oiled it, bent anything or fouled it up. I've been using it for a good while and I've loaded about 3,450 rounds (all single stage!) since Christmas, checking my Lyman 55 with this scale.

There is no monstrous problem with the scale... I just couldn't figure out why if all the weight in the pan is hanging from that loop, it should matter in any way how the pan was placed on the scale.

I like the monofilament flishing line idea. I'd probably go nuts trying to tie a little knot and make a loop of that size...

And for the folks who are looking WAY too closely at the linked picture and not reading the TEXT very well, that's a Gunblast photo that I linked just to show you the model/brand of my scale. It's a picture for reference. That's not my scale, not my bench and I don't have it adjusted like you see in the photo. I didn't even take that photo... I found it in a quick web search just so you could see the scale that I'm talking about.

engineermike

Moderator

Try some alcohol wipes and go over everything or get a clean brush and brush everything off and check everything that hangs and be sure everything is free to move and then pick up the phone and call dillon and ask them why their scale will not work.

Jbar4Ranch

New member

I'd have to agree with that. Kind of like... why does my bathroom scale register the same weight whether I'm standing on one leg or two...wncchester said:The location of the pan on the hanger is transfered to the beam's loop by the hanger's hook, it should make no difference at all how the pan sits on the hanger.

you will always have the same problem with the counter balence scales unles you place it dead center every time you will have varience.

Wrong (assuming the scale is working as designed), as both common sense and the results of my experiment (did you read that post?) indicate.

Edward429451

Moderator

I have a 5 0 5 scale and it has always worked fine but I do remember once when my scale wanted to be difficult in a similar way and as it turned out, the sliding adjuster for the X10 scale (the one that you can not observe sitting in the groove) was misaligned just a tad. I blew it out real good and made sure everything was clean and suddenly it started working again.

I've used this scale for ~ 25 years and it is not touchy or persnickety. Theres not that much to go wrong!

I've used this scale for ~ 25 years and it is not touchy or persnickety. Theres not that much to go wrong!

in the pic of the scale, what is the pill bottle for?

Oil to damp the scale movement out.

Used before magnetic dampers came into wide use.

wncchester

New member

" Kind of like... why does my bathroom scale register the same weight whether I'm standing on one leg or two..."

Exactly.

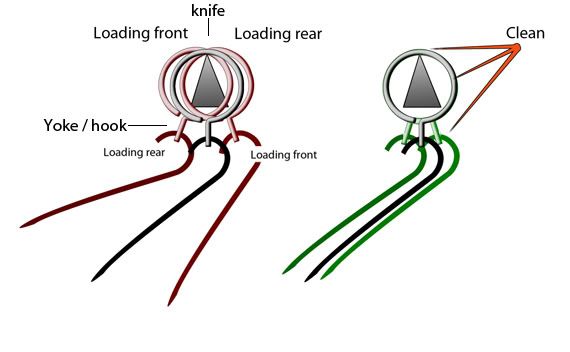

Tater's illustration shows what I meant about cleaning the beam loop the pan hanger connects to.

Exactly.

Tater's illustration shows what I meant about cleaning the beam loop the pan hanger connects to.

Breeze, ceiling fan, air register. It doesn't even have to be blowing in that direction to cause variance. If it is blowing into the room at all, it can cause a real delema. I've closed all the registers in my reloading room because I got tired of waiting for the heat or AC to cycle off so I could continue with the powdering process.

oneounceload

Moderator

.1 difference could be easily from the powder dispenser as well. Mty 5-10 RCBS scale does not have any variation like that - I tried what someone else did earlier and got the same result - no difference

It's not a breeze, or air movement of any kind.Breeze, ceiling fan, air register. It doesn't even have to be blowing in that direction to cause variance.

It's also not coming from my powder measure...

Jeez, I'm talking about taking the same pan with the same charge in it and twisting it one eighth of an inch so it's sitting in the holder so slightly differently. That's all.

We aren't trying to solve every scale problem on every load bench here.

Hkbullseye

Inactive

Found my scale problem!

I don't resurrect posts this old lightly... sorry but I have to explain.

OP, I had the same issues for 2 YEARS, I have a Dillon and most recently bought a RCBS scale, I realized they are almost the same. So last night I was struggling with shifting zero on my scales, and I tilted the empty pan all the way in each direction, one at a time, and gently return it to level. My zero would go from ultra low to ultra high. So I decided to remove the balls inside the base.

After opening the bottom I found it full of Aluminum shavings along with the balls! So the free movement was totally jammed, and each time I tilted the pan, the mass of shavings and balls would remain shifted to that side.

Removed it all, returned the clean ball bearings and problem solved. I took apart both scales this way, SAME PROBLEM FOR BOTH!!! I struggled for the last 2 years since I began reloading.

Check your scales(1 Philips screw) how many have shavings????

Thanks and by the way I'm a new guy from NY and glad I found this excellent post, happy to be a part of the forum. Thanks

I don't resurrect posts this old lightly... sorry but I have to explain.

OP, I had the same issues for 2 YEARS, I have a Dillon and most recently bought a RCBS scale, I realized they are almost the same. So last night I was struggling with shifting zero on my scales, and I tilted the empty pan all the way in each direction, one at a time, and gently return it to level. My zero would go from ultra low to ultra high. So I decided to remove the balls inside the base.

After opening the bottom I found it full of Aluminum shavings along with the balls! So the free movement was totally jammed, and each time I tilted the pan, the mass of shavings and balls would remain shifted to that side.

Removed it all, returned the clean ball bearings and problem solved. I took apart both scales this way, SAME PROBLEM FOR BOTH!!! I struggled for the last 2 years since I began reloading.

Check your scales(1 Philips screw) how many have shavings????

Thanks and by the way I'm a new guy from NY and glad I found this excellent post, happy to be a part of the forum. Thanks

JeepHammer

Moderator

One tip...

Turn the beam up side down,

Knife edges pointing 'Up' when not in use.

This keeps normal vibration from dulling knife edges while not in use.

Just removing the pan and letting the scale beam drop isn't enough.

When I lived next to a highway where big trucks rumbled by I left the beam in the cradle unused for about two years while deployed (military) on a brand new scale.

When I got back to that scale (pan off beam, box turned up side down over scale) the vibration of everyday life had blunted the knife edges, and had worn a groove in the saddles.

It's very easy to remove hanging pan from beam and turn the beam over so the knife edges & saddle isn't worn down when not in use.

Turn the beam up side down,

Knife edges pointing 'Up' when not in use.

This keeps normal vibration from dulling knife edges while not in use.

Just removing the pan and letting the scale beam drop isn't enough.

When I lived next to a highway where big trucks rumbled by I left the beam in the cradle unused for about two years while deployed (military) on a brand new scale.

When I got back to that scale (pan off beam, box turned up side down over scale) the vibration of everyday life had blunted the knife edges, and had worn a groove in the saddles.

It's very easy to remove hanging pan from beam and turn the beam over so the knife edges & saddle isn't worn down when not in use.

JeepHammer

Moderator

HK Bullseye, I got one with flat spots on the lead shot, shot WOULDN'T find the 'Low' spot and stay put...

Every time I took a charge off the pan/beam the shot would shift and not find the low spot.

Round shot that would roll freely solved the issue, same as you.

Every time I took a charge off the pan/beam the shot would shift and not find the low spot.

Round shot that would roll freely solved the issue, same as you.

Hkbullseye

Inactive

Jeep, good to know you had a similar experience. My RCBS has lead shot, but the Dillon has SS ball bearings, so it seems there is a quality difference based on resellers spec even for the same manufacturer. I just can't believe these scales are going out with the aluminum drill shavings stuck in with the ball bearings... really hoping to hear if others have it as well.

edward hogan

New member

If it is the accuracy variation that is the main concern, and if you want positive surety of your weight; get a Check Weight Set. I use the RCBS Deluxe Check Weight Set and can always setup my scale to be zeroed right on the money for the load I choose or within a grain or fraction.

Another option that may assist is to use something like a heavy pane of glass or a plastic veneered shelf board which has absolute flat and non-static surface.

Until you have a calibration weight set, you will be guessing. Using bullets might get you close, but few of them are going to be right on. A Check Weight Set is a real must if you load at maximum charge levels.

Another option that may assist is to use something like a heavy pane of glass or a plastic veneered shelf board which has absolute flat and non-static surface.

Until you have a calibration weight set, you will be guessing. Using bullets might get you close, but few of them are going to be right on. A Check Weight Set is a real must if you load at maximum charge levels.