So as an engineer I have to ask this question....what kind of

jack azz

jack azz

designs a firearm to use a wedge to hold a barrel onto a frame?...oh yeah, that'd be Samuel Colt. Sammy must have gone to the same school as those guys who design cars where you have to remove one of the motor mounts and jack the car engine up to remove the oil filter.

designs a firearm to use a wedge to hold a barrel onto a frame?...oh yeah, that'd be Samuel Colt. Sammy must have gone to the same school as those guys who design cars where you have to remove one of the motor mounts and jack the car engine up to remove the oil filter.

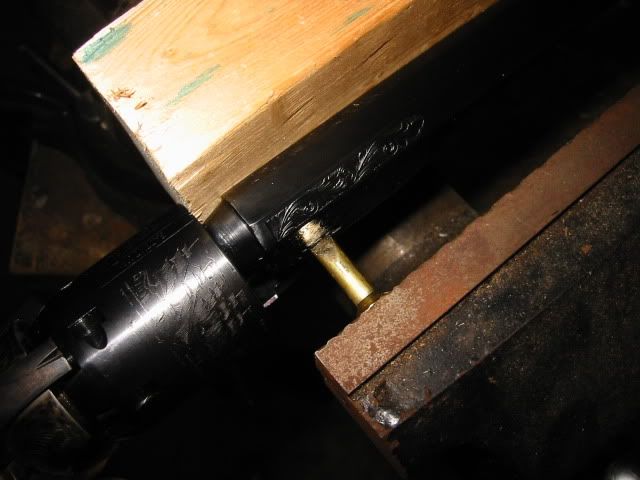

Okay, next question. Anyone have any suggestions for removing said wedge out of a Pietta 1851 Navy revolver? So I turned a copper penny on is side and held it with a pair of plyers on the right side of the wedge and beat on it until the copper penny was destroyed. Wedge didn't even budge. The wedge is sitting almost flush on the right hand side. Maybe I just need to shoot the crap outta it one day with the largest charges I can fit in the cylinder...maybe that'll loosen things up.

So far I'm a big fan of the Remington 1858 and the ROA. Sammy can bite me on the azz for now.

Okay, next question. Anyone have any suggestions for removing said wedge out of a Pietta 1851 Navy revolver? So I turned a copper penny on is side and held it with a pair of plyers on the right side of the wedge and beat on it until the copper penny was destroyed. Wedge didn't even budge. The wedge is sitting almost flush on the right hand side. Maybe I just need to shoot the crap outta it one day with the largest charges I can fit in the cylinder...maybe that'll loosen things up.

So far I'm a big fan of the Remington 1858 and the ROA. Sammy can bite me on the azz for now.