You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Offset Primer and a Bad Day for my Dies (not for faint of heart)

- Thread starter LBussy

- Start date

I don't think that they are worth the trouble, even if you do figure out a way to decap them without busting pins. Mainly because you will be in the same boat again next time.

.223 brass is too plentiful to waste time fooling with a bad batch. It is almost painful to let go a batch of nice looking brass, like that FNB appears to be, but the time and effort don't appear to be worth it. It looks like you were able to cull out some of the brass that looks serviceable... that's a good thing.

Like one of the other posters mentioned, read the directions on the OneShot. I stuck about 4 cases before I actually read and followed the directions, now I don't have that problem. True story. And I'm talking some big cases like .30-06 and .348.

That's my first thought, too. Let the carrier evaporate. I use a number of case lubes, both wipe-on and spray. I've had stuck cases with both. The only system that seems to work flawlessly for spray is I dilute Lee case lube about 10:1 in rubbing alcohol (70%) and spray it on and let it dry, and then spray on the canned lube and let it set an hour or two as well. Two layers seems to work better than one. For rub-on, I've become partial to Hornady Unique. I used Imperial Sizing Wax for a long time, but Unique seems to work as well and is considerably more economical. It is easier to get too much on, though, and wind up with neck indentations.

The off-center flash holes are caused either by drilling without adequate support for the drill to stop if from walking, or by not centering the case over the drill. I believe all mil spec case brass is drilled.

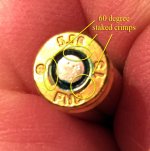

As the others commented, you have a form of what is called a staked crimp on that case.

If the cases are gritty, they should be cleaned with a rag or even tumbled in dry corncob for a bit to remove that.

The off-center flash holes are caused either by drilling without adequate support for the drill to stop if from walking, or by not centering the case over the drill. I believe all mil spec case brass is drilled.

As the others commented, you have a form of what is called a staked crimp on that case.

If the cases are gritty, they should be cleaned with a rag or even tumbled in dry corncob for a bit to remove that.

Attachments

On using Ohe Shot. I've used it since it came out. It works well for me and has never given me a stuck case.

Before using it, shake it well and spray the cases. Don't let those cases sit very long and resize them. Before applying it to the next cases shake it again and follow the above.

Whatever is in that can separates so you have to constantly shake it before applying it to brass.

The stuff works great as long as you shake the can first.

Before using it, shake it well and spray the cases. Don't let those cases sit very long and resize them. Before applying it to the next cases shake it again and follow the above.

Whatever is in that can separates so you have to constantly shake it before applying it to brass.

The stuff works great as long as you shake the can first.

Well when it says 5.56 you can be sure its military ammo and its going to be staked.

That is a NATO symbol on the left. It may have stuff on the case as well.

FNB is noted for the off center holes, its a one fire and done thing. NATO does note care.

I would not touch it, you can pick up good brass all day long at the range (or buy it second hand)

One shot has some issues if not used right, I over spray it and does fine.

I did not know about stuck case remover either, I actually drilled a case out of a die one time.

Case remover more better.

That is a NATO symbol on the left. It may have stuff on the case as well.

FNB is noted for the off center holes, its a one fire and done thing. NATO does note care.

I would not touch it, you can pick up good brass all day long at the range (or buy it second hand)

One shot has some issues if not used right, I over spray it and does fine.

I did not know about stuck case remover either, I actually drilled a case out of a die one time.

Case remover more better.

It was a chicken or the egg thing for me ... I was de-priming so I could wet clean. Now that I have the universal decapping die I won't have this issue again - at least not from dirty brass.Now take your decapped brass and get it clean. This process has evolved some.I still use a vibratory bowl and media.Only run clean brass into your sizing die.

That might be another problem. I'm sure I only waited a minute or two.Now you must wait,at least 15 min.30is better. The volatile carrier must evaporate before sizing,or you will stick cases.

One Shot gets a lot of bad press and yet I know there are a lot of folks who use it with success. What I've normally used is Dillon. These were my first stuck cases in over five years of reloading which is what gets me. It's true, the brass was not cleaned first, but this was not random outdoor range pickup stuff. This was my brass, picked up off a concrete floor. I've done this before.

I can't argue with the fact that I stuck a case; twice. So, I'm left with blaming dirt, or blaming One Shot. The easiest thing would be to avoid both ever gain.

And that's what I'll be using. A friend is going to lend me his so I can try it out.In my experience,the Dillon bench tool ($100) works really well.

And that will be my sequence as well, except I use stainless steel media.I have never had a stuck case, maybe because of my sequence of operations. I decap everything and then use an ultrasonic cleaner before the brass touches my dies.

You know you jinxed yourself by saying that though, right?

With the universal decapper I had no issues at all so I can salvage the entire batch..223 brass is too plentiful to waste time fooling with a bad batch. It is almost painful to let go a batch of nice looking brass, like that FNB appears to be, but the time and effort don't appear to be worth it.

I can see that in the picture (darned old eyes) and I can definitely see it now that they are cleaned of that sealer.As the others commented, you have a form of what is called a staked crimp on that case.

Like I said, now that I have the universal decapper I won't be tempted to use the sizing/decapping die on dirty brass. I have a pile of brass (including range pickups) that I need to swage so I'll put them in that pile and do them all some Saturday afternoon when I'm bored.

The die is already out in the mailbox. Hopefully I never have to do this again but if I do I'll be sure to try that too.It is better when it doesn't just tear the whole head off the case, as once happened to me. I recommend putting the die in your freezer for a couple of hours before trying it. Brass shrinks a little more than steel does in the cold. If you have dry ice, colder is better.

Don't forget to get a little tool to remove that pesky crimp with. If you don't cut the crimp completely away it will give you trouble seating new primes.

I use the Lyman Primer Pocket Reamer first, to remove the crimp , then finish up with the Lyman Primer Pocket Uniformer, this makes all the pockets to SAAMI specifications. After the case is done you won't have to do it again.

Gary

I use the Lyman Primer Pocket Reamer first, to remove the crimp , then finish up with the Lyman Primer Pocket Uniformer, this makes all the pockets to SAAMI specifications. After the case is done you won't have to do it again.

Gary

Been down that road before ... too tedious for me. I'll be using this:Don't forget to get a little tool to remove that pesky crimp with. If you don't cut the crimp completely away it will give you trouble seating new primes.

I use the Lyman Primer Pocket Reamer first, to remove the crimp , then finish up with the Lyman Primer Pocket Uniformer, this makes all the pockets to SAAMI specifications. After the case is done you won't have to do it again.

I'm not sure how much swaged brass I'll need to de-swage before it pays for itself, but that's not important right now!

Attachments

Stats Shooter

New member

Like I said. I busted two decapping pins on that exact brass using an RCBS universal decapping die.

I had picked up several at the range and they were in with some other range brass. Staked primers isn't a problem for my decapping dies. They come out a little harder, but nothing remarkable.

However!!!! Off center flash holes are a problem. So I pitched all that worthless stuff because I wasn't going to waste time swaging, cleaning, etc.. brass with flash holes I would be fighting until I got rid of it.

I had picked up several at the range and they were in with some other range brass. Staked primers isn't a problem for my decapping dies. They come out a little harder, but nothing remarkable.

However!!!! Off center flash holes are a problem. So I pitched all that worthless stuff because I wasn't going to waste time swaging, cleaning, etc.. brass with flash holes I would be fighting until I got rid of it.

I'm not sure if the Lee decapping pin is more flexible or what, but I de-primed all of my brass with no issues after that first debacle.Like I said. I busted two decapping pins on that exact brass using an RCBS universal decapping die.

LBussy wrote:

I tried de-priming this evening. The first one stuck in the die, thanks One-Shot.

Put your cases in a plastic bag. Spray them with One-Shot. Let it have time to dry thoroughly. Every time I have heard of someone getting a case stuck with One-Shot, they didn't wait for it to dry sufficiently.

If you're in a hurry and can't wait for One-Shot to dry, try Hornady Unique or Imperial Sizing Wax.

So aside from that I noticed it took a LOT of pressure to get the primer out. They don't seem to be swaged or staked (or are they?).

The primers are clearly staked. See unclenick's post for more information.

They are sealed with some green sealant. Anyone ever seen/experienced that?

I have never noticed primer sealant materially increasing the pressure required to decap a case. It seems more like that the additional resistance was caused by the brass having been shot in a "losse" chamber and so required more effort to restore to original dimensions.

Finally, and this might contribute to them being hard to de-prime: I noticed that the flash hole is off-center. ...seems very strange to me that they are off-center. Anyone else seen this?

I have not run across FNB headstamp brass before, but I have come across many other headstamps that routinely have the flashhole off-center. If you're a precision (i.e. five shots, one hole) shooter the off-center flash hole could make a difference. Otherwise, it will not.

If you're going to use range brass which may have off-center flashholes or may be Berdan primed, I suggest you get a universal decapping die and decap all your brass early on in your reloading process.

gwpercle wrote:

Don't forget to get a little tool to remove that pesky crimp with. If you don't cut the crimp completely away it will give you trouble seating new primes.

I choose to ream the primer pocket crimp. I use a 45 degree countersink chucked into a drill press. I raise the case to the spinning countersink, rotate it about a third of a turn between my thumb and index finger and I'm done.

All of the stuck case removers I have seen rely on the ability to drill a hole. If you'll notice the decapping pin is still in there and I can't get it out either.Stuck case removers can be made from common items.A nut such as 5/8-11,a fender washer with a 5/16 hole,a 1/4-20 tap,No 7 drill bit,a 1/4-20 socket head screw,and an allen wrench.

The die is on it's way back to Lee for ... well, to let the guys at Lee see how badly I screwed things up and give them a good laugh.

Looking at the mangled rim in he OP, you are not removing the stuck case properly.

This is a 24 second video showing you the entire process to remove a stuck case from Lee dies.

https://www.youtube.com/watch?v=Ylp3fsYrEVw

If you are more of a reader than watcher the directions are also in the instructions that come with the dies, #2 Stuck case

https://leeprecision.com/cgi-data/instruct/RM3508.pdf

Now that you got it out, find the nearest trash can and deposit the Hornady oneshot in it and go get some decent case lube before proceeding.

I suppose you can get away with using the spray one shot on pistol cases but I don’t like it for rifle and it looks like your results are not any better. If you want to stick (no pun intended) to Hornady products use their unique case lube, it’s about 1.2 billion times better, for rifle cases.

https://www.midwayusa.com/product/758495/hornady-unique-case-lube-4-oz-tub

This is a 24 second video showing you the entire process to remove a stuck case from Lee dies.

https://www.youtube.com/watch?v=Ylp3fsYrEVw

If you are more of a reader than watcher the directions are also in the instructions that come with the dies, #2 Stuck case

https://leeprecision.com/cgi-data/instruct/RM3508.pdf

Now that you got it out, find the nearest trash can and deposit the Hornady oneshot in it and go get some decent case lube before proceeding.

I suppose you can get away with using the spray one shot on pistol cases but I don’t like it for rifle and it looks like your results are not any better. If you want to stick (no pun intended) to Hornady products use their unique case lube, it’s about 1.2 billion times better, for rifle cases.

https://www.midwayusa.com/product/758495/hornady-unique-case-lube-4-oz-tub

Last edited:

I've put this formula out before, so I'll put it out once again for those who have missed it. Put away the Hornady One Stuck, this is MUCH better and cheaper to boot. This homemade lanolin spray lube is the only way to go for bottleneck cases. I processed brass commercially for a guy with a Type 6 FFL for several years, and here is the recipe I used:

First, buy a 4 ounce bottle of liquid lanolin online (Amazon or eBay) for about $8. Second, buy a bottle of HEET fuel line antifreeze ($3), available at Walmart or any automotive supply store. Then buy a cheap plastic spray bottle at a local Dollar store. Heat some water on the stove, then turn it off. Place the bottles of lanolin and HEET into the hot water, BUT NOT WITH A FLAME UNDER THE WATER. Now pour 1/4 of the warmed up lanolin bottle (1 ounce) and all of the warmed up HEET bottle (12 ounces) into the spray bottle and shake to mix the contents. You now have one of the best lubes there is that will last for 1,000's of cases. To use it, dump your brass into either a box or large plastic bag, give it a couple of squirts, and shake and roll the brass around to distribute the lube evenly. You will be be amazed at how well this lube works and will never use anything else again. To remove the lube after sizing, dump the brass into your dry tumbler, add a shot of mineral spirits and tumble for 20 minutes. It's that simple. However, if you insist on using One Stuck, here is another Hornady product to order with it:

https://www.midwayusa.com/product/131002/hornady-stuck-case-remover

Hope that helps.

Don

First, buy a 4 ounce bottle of liquid lanolin online (Amazon or eBay) for about $8. Second, buy a bottle of HEET fuel line antifreeze ($3), available at Walmart or any automotive supply store. Then buy a cheap plastic spray bottle at a local Dollar store. Heat some water on the stove, then turn it off. Place the bottles of lanolin and HEET into the hot water, BUT NOT WITH A FLAME UNDER THE WATER. Now pour 1/4 of the warmed up lanolin bottle (1 ounce) and all of the warmed up HEET bottle (12 ounces) into the spray bottle and shake to mix the contents. You now have one of the best lubes there is that will last for 1,000's of cases. To use it, dump your brass into either a box or large plastic bag, give it a couple of squirts, and shake and roll the brass around to distribute the lube evenly. You will be be amazed at how well this lube works and will never use anything else again. To remove the lube after sizing, dump the brass into your dry tumbler, add a shot of mineral spirits and tumble for 20 minutes. It's that simple. However, if you insist on using One Stuck, here is another Hornady product to order with it:

https://www.midwayusa.com/product/131002/hornady-stuck-case-remover

Hope that helps.

Don

I tried that. It was not budging and if you had it in your hand you would see it started to bulge the end of the case. Here's the PDF instructions for those following along at home:Looking at the mangled rim in he OP, you are not removing the stuck case properly.

This is a 24 second video showing you the entire process to remove a stuck case from Lee dies.

https://www.youtube.com/watch?v=Ylp3fsYrEVw

If you are more of a reader than watcher the directions are also in the instructions that come with the dies, #2 Stuck case

https://leeprecision.com/cgi-data/instruct/RM3508.pdf

The rim is mangled because, as you suspected, I used vice grips after that to try to get it out. No luck there either. I'm pretty sure the folks @ Lee will have to toss it and send me a new one. That or they will mount it on the wall of shame. I'm sure they have one.Stuck Case If a case is not lubricated, the rim will be pulled off and the case remains stuck in the die. If this happens — loosen, but do not remove the decapper clamp with a 3/4” and 1/2” wrench. Use a 3/16” drift punch and large hammer (1-lb. or larger) to tap on the decapper rod and drive the stuck case free. Lee Precision will remove a stuck case for $6.00.

I'm either going back to the Dillon lube ($$) or something on a pad. I'll save the One-Shot for ... I don't know. Something not having to do with a rifle cartridge and a sizing die. As I've said, I know there are people that use it with good results but I won't do it again.Now that you got it out, find the nearest trash can and deposit the Hornady oneshot in it and go get some decent case lube before proceeding.

I suppose you can get away with using the spray one shot on pistol cases but I don’t like it for rifle and it looks like your results are not any better. If you want to stick (no pun intended) to Hornady products use their unique case lube, it’s about 1.2 billion times better, for rifle cases.

https://www.midwayusa.com/product/758495/hornady-unique-case-lube-4-oz-tub