You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

new memebr and new to reloading, need help

- Thread starter REVOLVERfan

- Start date

Prof Young

New member

Go for it . . . carefully.

There is indeed a lot to learn.

When I started I read a couple of reloading books and then for my first loads I simply followed the formulas and the instructions that came with my dies. Worked pretty well. I was a year into reloading before I learned about primers that came in different "numbers" like the Remington primers. For the most part, other than standard or magnum, small or large and rifle or pistol, a primer is a primer is a primer. And most primer manufacturers treat it that way too. I'm thinking Remington is the only one with different numbered primers.

Anyway the main thing is to stay safe. If the formula calls for a #2 primer then use that. The formulas I follow don't call for a specific # primer.

44 mag was my first reloading and I was so careful and nervous that I put the gun in a handgun vice and pulled the trigger with a lanyard for my first reloads.

Beware of minimum loads and lee powder dippers. The combination of those two things gave me some very dangerous squibs. Not a good thing.

Live well, be safe

Prof Young

There is indeed a lot to learn.

When I started I read a couple of reloading books and then for my first loads I simply followed the formulas and the instructions that came with my dies. Worked pretty well. I was a year into reloading before I learned about primers that came in different "numbers" like the Remington primers. For the most part, other than standard or magnum, small or large and rifle or pistol, a primer is a primer is a primer. And most primer manufacturers treat it that way too. I'm thinking Remington is the only one with different numbered primers.

Anyway the main thing is to stay safe. If the formula calls for a #2 primer then use that. The formulas I follow don't call for a specific # primer.

44 mag was my first reloading and I was so careful and nervous that I put the gun in a handgun vice and pulled the trigger with a lanyard for my first reloads.

Beware of minimum loads and lee powder dippers. The combination of those two things gave me some very dangerous squibs. Not a good thing.

Live well, be safe

Prof Young

ShootistPRS

New member

RevolverFan,

As far as using different components go, you can usually get away with starting loads and work your loads up to an accuracy that is under the maximum loads. There are at least two manuals that you should have;

1. the manual from the bullet manufacturer for the bullets you use

and

2. the manual from the powder manufacturer of the powder that you use

I have an ever-growing number of manuals to grab the information for my reloading. I follow the information in them with a bit of caution because the powder I am using may not be listed in the bullet manufacturers manual so I check for any trend differences in powders listed in both manuals. This information will give you information about why the differences exist - a pistol bullet seated deeper leaves less space for the powder so pressures can be higher in the case with the bullet seated deeper. You can decide to start your load a bit lighter and know that you are likely to hit maximum pressures with less powder too.

You should keep records of every load - not ust the ones that work well because ten years from now you may wonder how a different powder will work in your gun forgetting that you tried it in the past and it flopped.

I keep my reload records on my computers and print them out for the three ring binder for each gun. I have load data that goes back to 1968.

As far as using different components go, you can usually get away with starting loads and work your loads up to an accuracy that is under the maximum loads. There are at least two manuals that you should have;

1. the manual from the bullet manufacturer for the bullets you use

and

2. the manual from the powder manufacturer of the powder that you use

I have an ever-growing number of manuals to grab the information for my reloading. I follow the information in them with a bit of caution because the powder I am using may not be listed in the bullet manufacturers manual so I check for any trend differences in powders listed in both manuals. This information will give you information about why the differences exist - a pistol bullet seated deeper leaves less space for the powder so pressures can be higher in the case with the bullet seated deeper. You can decide to start your load a bit lighter and know that you are likely to hit maximum pressures with less powder too.

You should keep records of every load - not ust the ones that work well because ten years from now you may wonder how a different powder will work in your gun forgetting that you tried it in the past and it flopped.

I keep my reload records on my computers and print them out for the three ring binder for each gun. I have load data that goes back to 1968.

There is a difference between how load manuals use SAAMI pressure information and how manufacturers use it, with the manuals erring on the safe side of the line. The common SAAMI pressure limit is called the Maximum Average Pressure (MAP) and for a manufacturer is an average peak pressure value for ten shots using pressure guns calibrated by firing reference loads (to see to it that their technician running their equipment is getting a matching pressure). They have other, higher pressure numbers that, based on statistics, allows for a second random ten shot sample to have a different average and the have a limit for how much higher it can be, and another for a ten shot sample taken when the lot has aged a certain amount, and a limit for the extreme spread of the ten rounds fired in the MAP. Those other pressures are numbers most handloaders are not even aware of, and they wouldn't really help a lot if they were because most handloaders don't have pressure guns and reference ammunition.

So load manuals from the bullet and powder companies don't work the way manufacturers do. Hodgdon explains this in their print manual. It says they treat the SAAMI MAP as an absolute limit rather than an average. For this reason, if one powder is producing more peak pressure variation from shot-to-shot in their tests than another does, they will stop increasing the load at a lower pressure than they will for a very consistent load. This is to ensure the probability of a load exceeding the MAP is minimized. Indeed, Hodgdon even states that if you select a powder from their load data that has a maximum pressure given that is highest (closest to the MAP value), you know that powder exhibited the least shot-to-shot peak pressure variation in their testing.

I don't know the manual author's exact criteria, but would guess they limit the maximum peak pressure to a couple of their test load's standard deviations below the MAP. The reason for this apparent abundance of caution is simple: despite quality control efforts there is some burn rate and bulk density and moisture and solvent content variation among powders by the time they are actually loaded, and they can't control anything beyond the condition when it leaves the factory. So they feel a need to allow something for normal variations between when the data is published and when the powder is actually used. There is some good information about the effect of moisture and solvent content on burning rates in the Norma manual, which I find more completely informative than most others because of that information. I recommend it just for reading the information that precedes its load data. A nod to board member Mete for conveying the heads up on this manual as a good resource.

RC20,

Glad you got to read the article. Jone's article on primers is also good if you haven't read it. But apropos of the bullet difference article, the Norma manual I just mentioned states on page 148:

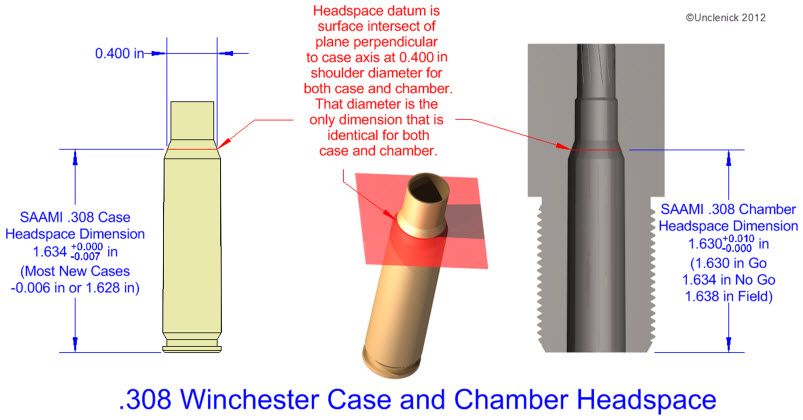

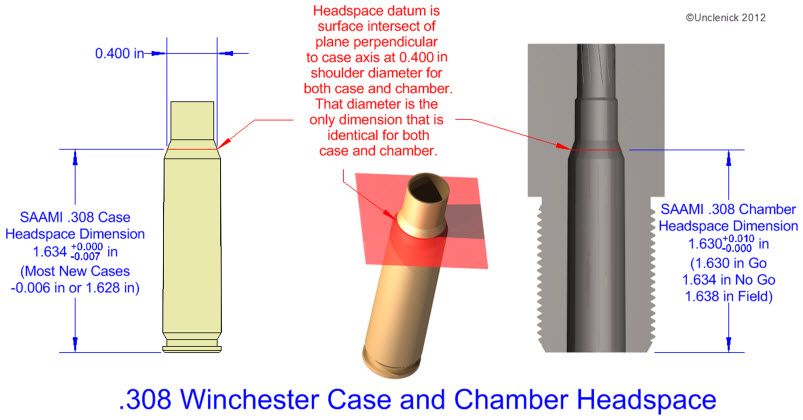

Below is an old illustration of the headspace datum plane I did, just to throw in another way of looking at it and to emphasize that the datum (singular form of data) is a reference measurement (can be a plane or a point or any other definable reference) and is the only dimension that both the cartridge and chamber have in common. Since the datum is a reference dimension it has no tolerance, but rather is a basic measurement value. All tolerances are figured either with respect to that value or to one another while not moving or changing that value. The term "datum" is also used in refiguring machine tools. You pick the datum point or plane from which all else is figured, including right angles and tolerances (I've done a little scraping in my time.)

Notice in the above that the tolerance for headspace is 0.002" larger than the Field Reject gauge value commonly produced. I don't know why, other than they have to allow for the gauges to be off a little, too, and I've had some inexpensive ones that were off by that much.

So load manuals from the bullet and powder companies don't work the way manufacturers do. Hodgdon explains this in their print manual. It says they treat the SAAMI MAP as an absolute limit rather than an average. For this reason, if one powder is producing more peak pressure variation from shot-to-shot in their tests than another does, they will stop increasing the load at a lower pressure than they will for a very consistent load. This is to ensure the probability of a load exceeding the MAP is minimized. Indeed, Hodgdon even states that if you select a powder from their load data that has a maximum pressure given that is highest (closest to the MAP value), you know that powder exhibited the least shot-to-shot peak pressure variation in their testing.

I don't know the manual author's exact criteria, but would guess they limit the maximum peak pressure to a couple of their test load's standard deviations below the MAP. The reason for this apparent abundance of caution is simple: despite quality control efforts there is some burn rate and bulk density and moisture and solvent content variation among powders by the time they are actually loaded, and they can't control anything beyond the condition when it leaves the factory. So they feel a need to allow something for normal variations between when the data is published and when the powder is actually used. There is some good information about the effect of moisture and solvent content on burning rates in the Norma manual, which I find more completely informative than most others because of that information. I recommend it just for reading the information that precedes its load data. A nod to board member Mete for conveying the heads up on this manual as a good resource.

RC20,

Glad you got to read the article. Jone's article on primers is also good if you haven't read it. But apropos of the bullet difference article, the Norma manual I just mentioned states on page 148:

"Careful laboratory testing by M. L. McPherson & Bill Falin demonstrated a 32.4% pressure variation in peak pressure, in otherwise identical 270 Winchester loads, using various 150-grain bullets."

Below is an old illustration of the headspace datum plane I did, just to throw in another way of looking at it and to emphasize that the datum (singular form of data) is a reference measurement (can be a plane or a point or any other definable reference) and is the only dimension that both the cartridge and chamber have in common. Since the datum is a reference dimension it has no tolerance, but rather is a basic measurement value. All tolerances are figured either with respect to that value or to one another while not moving or changing that value. The term "datum" is also used in refiguring machine tools. You pick the datum point or plane from which all else is figured, including right angles and tolerances (I've done a little scraping in my time.)

Notice in the above that the tolerance for headspace is 0.002" larger than the Field Reject gauge value commonly produced. I don't know why, other than they have to allow for the gauges to be off a little, too, and I've had some inexpensive ones that were off by that much.