RC20,

I'm curious why the paint and stick results would be any different? In the past I actually filed some dust off the stick and mixed it with alcohol to apply it in order not to have to pre-warm the case to get a smooth application. Seemed to work fine, too.

If you feel unsure about the liquids, you can bracket them with several temperatures at a time. See which ones melt simultaneously with the stick you like.

jugornot said:

I use the Sinclair hand priming tool which I feel the primer bottoming.

I have one of these, too, but since feeling the primer just kiss the bottom of the primer pocket does not set the bridge, as described in the article, I probably am using it a bit differently than you do. Setting the bridge means finding where the primer just bottoms out, then forcing it in approximately another 0.003" deeper. In the 70's, Remington and Olin recommended anywhere from 0.002"-0.006" reconsolidation beyond touch-down, but Naval Ordnance at Indian Head did more detailed testing and and a decade later found 0.002-0.004" was optimal for reliability and consistency of ignition on both large and small primers. Federal recommends 0.002" for their small primers and 0.003" for their large primers, but given that you usually have a couple thousandths of primer pocket depth variation (unless you uniform them) and primer anvil height variation, 0.003" is easier to achieve. The only direct way I know to hit a target exactly is with the K&M Primer Gauge tool, which zeros a dial indicator on the bottom of a primer pocket while simultaneously subtracting the height of the primer you choose to insert, all prior to actual seating. And then when you seat that primer in that pocket, the indicator is at zero when the anvil kisses the bottom of the pocket and you can read the additional consolidation on the indicator directly as you press the lever.

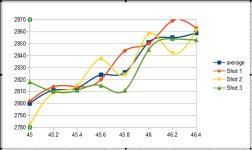

With the Sinclair tool, I use an entirely different approach. I either uniform the primer pocket depths or measure and sort them. I gently do the same with primer height. I then subtract the primer height from the pocket depth and add 0.003" to the result. I use shim washers between the Sinclair tool's body and the case clamping collar to set the protrusion of the primer ram protrusion to match that resultant number. I then prime by pushing the handle all the way to reach that depth setting. As Dan Hackett reported in '95, you can get your velocity SD's down this way.

jugornot said:

I read the article but do not lube after the SS media tumble which is right before priming.

You can try it pretty easily. I have not done a long-term study on it, but if you run a brush into the case mouth to slight scuff the surface, then apply the graphite and alcohol and let it dry, you create a layer of graphite between the bullet and the neck that should prevent most of the cold bonding that causes bullet pull to increase with the age of the cartridge. This is believed to be due to random quantum behavior of the valence electrons in the copper atoms becoming confused about whether they belong to an atom on the gilding metal surface or one on the brass surface over time, producing a substantial bond between the alloys. Board member Hummer70 has described measuring bullet pull on 7.62 ammo during his time at Aberdeen Proving Grounds that reached up to 600 lbs due to this phenomenon (60 lbs is the new ammo spec). But the bullet and case atoms have to make intimate contact for that to happen (something being shiny smooth encourages), so anything that prevents direct contact between the copper alloys mitigates the effect. Same with using coated bullets.

BTW, I found in the past that if you look closely (magnifier) at the case mouths of some commercial ammo, you can find copper scraped off the bullet in a little ring at the case mouth. This is due to the edges of the case mouth being sharp. The same happens with a freshly chamfered case. Despite the angle, the the corner it makes with the ID of the rest of the neck frequently has a wire edge burr and scrapes bullets and coatings. I found I could take a freshly chamfered case and insert and then pull a moly-coated bullet, and the pulled bullet would have no visible moly below the case mouth line. I also found burnishing the chamfer eliminated the problem. Bart Bobbit was familiar with this and suggested using an E-Z Out screw extractor in a drill for this. It has a left-hand conically tapered coarse "thread" pattern for extracting stuck screws. I polished one up that covers .22-45 cal case mouths. After trimming and chamfering, brief contact with it burnishes the sharp edge off. However, a little additional time in the SS pin tumbler after sizing and trimming and chamfering will do the same thing for you and allow coated bullets to keep their coatings.