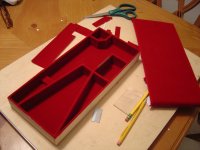

Step 7: veneer

Ok, I know I said in my original post that I wasn't going to veneer again. However, I really like the results of the first box, and I had enough of the fancy olive left to complete this one as well. Additionally, I used select pine for this box instead of white oak, and I much happier having done so. The first box has a carbide drill bit still lodged in it from where it broke off drilling a pilot hole! (try hand screwing brass screws into oak - broke a few of those as well. Oak is a really, REALLY hard wood!)

Now, there's a lot of complicated techniques and tools used for veneer. I just use plain old wood glue and a stack of bricks. Once the glue is dry, CAREFULLY trim the excess with a razor and sand trim.---j

Ok, I know I said in my original post that I wasn't going to veneer again. However, I really like the results of the first box, and I had enough of the fancy olive left to complete this one as well. Additionally, I used select pine for this box instead of white oak, and I much happier having done so. The first box has a carbide drill bit still lodged in it from where it broke off drilling a pilot hole! (try hand screwing brass screws into oak - broke a few of those as well. Oak is a really, REALLY hard wood!)

Now, there's a lot of complicated techniques and tools used for veneer. I just use plain old wood glue and a stack of bricks. Once the glue is dry, CAREFULLY trim the excess with a razor and sand trim.---j