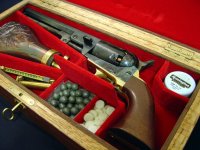

Hey fellas. Just had to show off some of my (amateur) woodworking. I’ve always wanted one of those neat deluxe wood cases that I’ve seen in my books for my 1851 Navy. Not finding a source for one anywhere in my price range, and being a something of a do-it-yourselfer always willing to bite off more than I can chew, I decided to try building one myself. It’s made completely from scratch out of ½” white oak, which imparts quite a bit of heft. The inner compartments are padded and fully lined with felt, and it’s lockable. The partition in the shot compartment (which which has its' own lid) can be moved or removed to accommodate more ammo. I got a little carried away and veneered it with fancy olive (something I wouldn’t do again.)

Thought you guys would appreciated it (more than my wife would anyways) ---j

Thought you guys would appreciated it (more than my wife would anyways) ---j