Magnum Wheel Man

New member

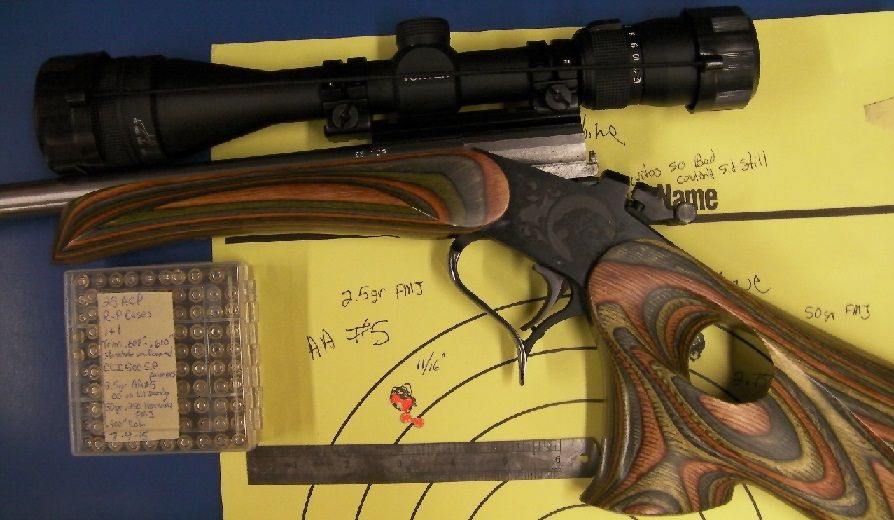

so, some of you may remember I built a Ruger Blackhawk chambered in 25 ACP... well... I've recently added a Contender barrel in the same, & had my custom 257 Special out along with the 25 ACP this weekend... please bear in mind, I am not & have never been a bullseye shooter... any groups posted were shot at 30 ft sitting at my bench, with my arms rested on the bench, & the guns unsupported... the 25 ACP is a mostly full case, I may try just a little more powder there, but am pretty happy with those loads... the 257 is starting loads with AA #5... when I 1st built the gun I had loaded some with Lil Gun, which I'll revisit after I've run through the AA#5 & AA#7 loads, in search of the tightest group... all groups are shot with a cylinder full ( both guns are 8 shot revolvers )

the 25 ACP's 1st...

currently wearing a new See All sight...

the 25 ACP's 1st...

currently wearing a new See All sight...

Last edited: