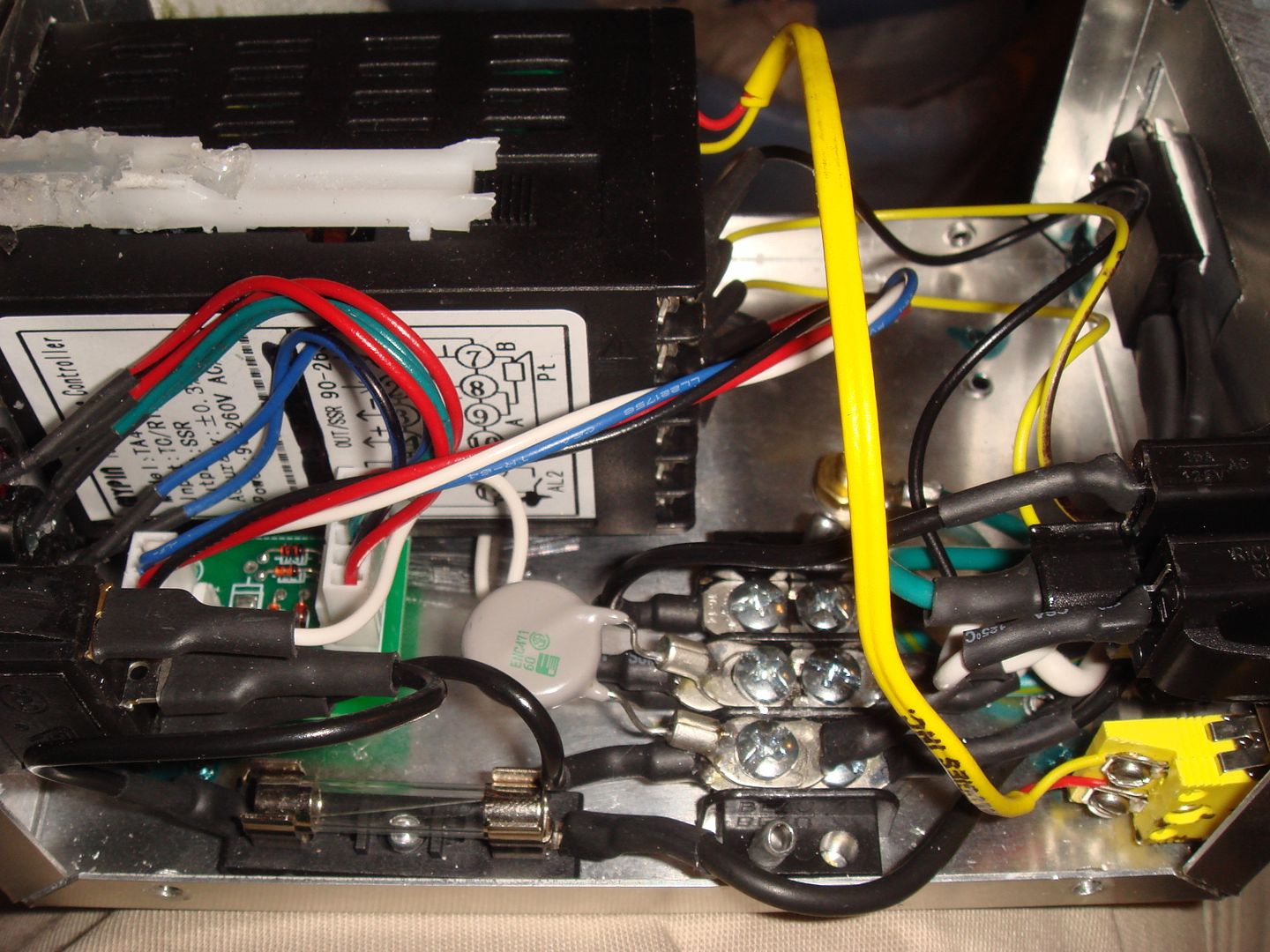

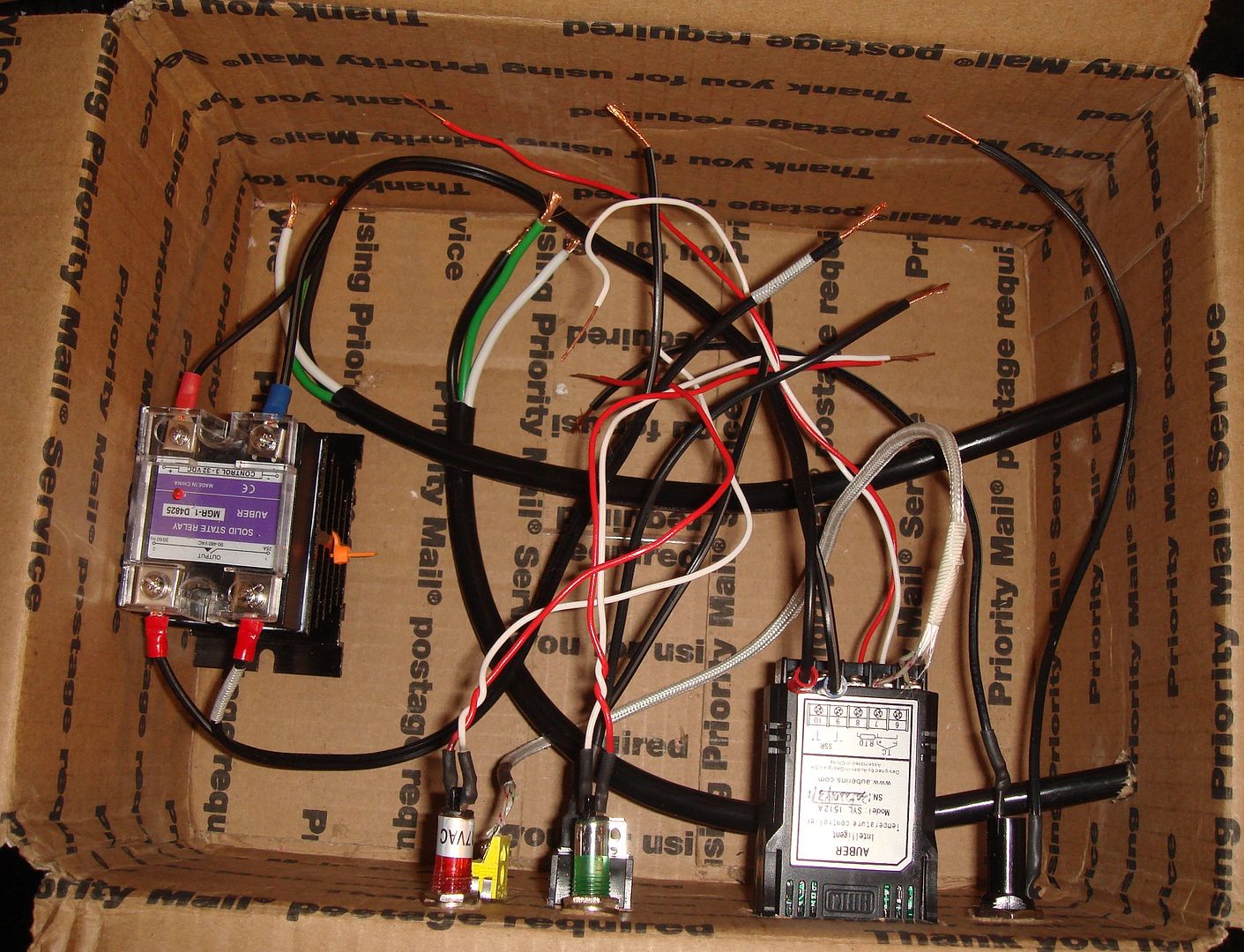

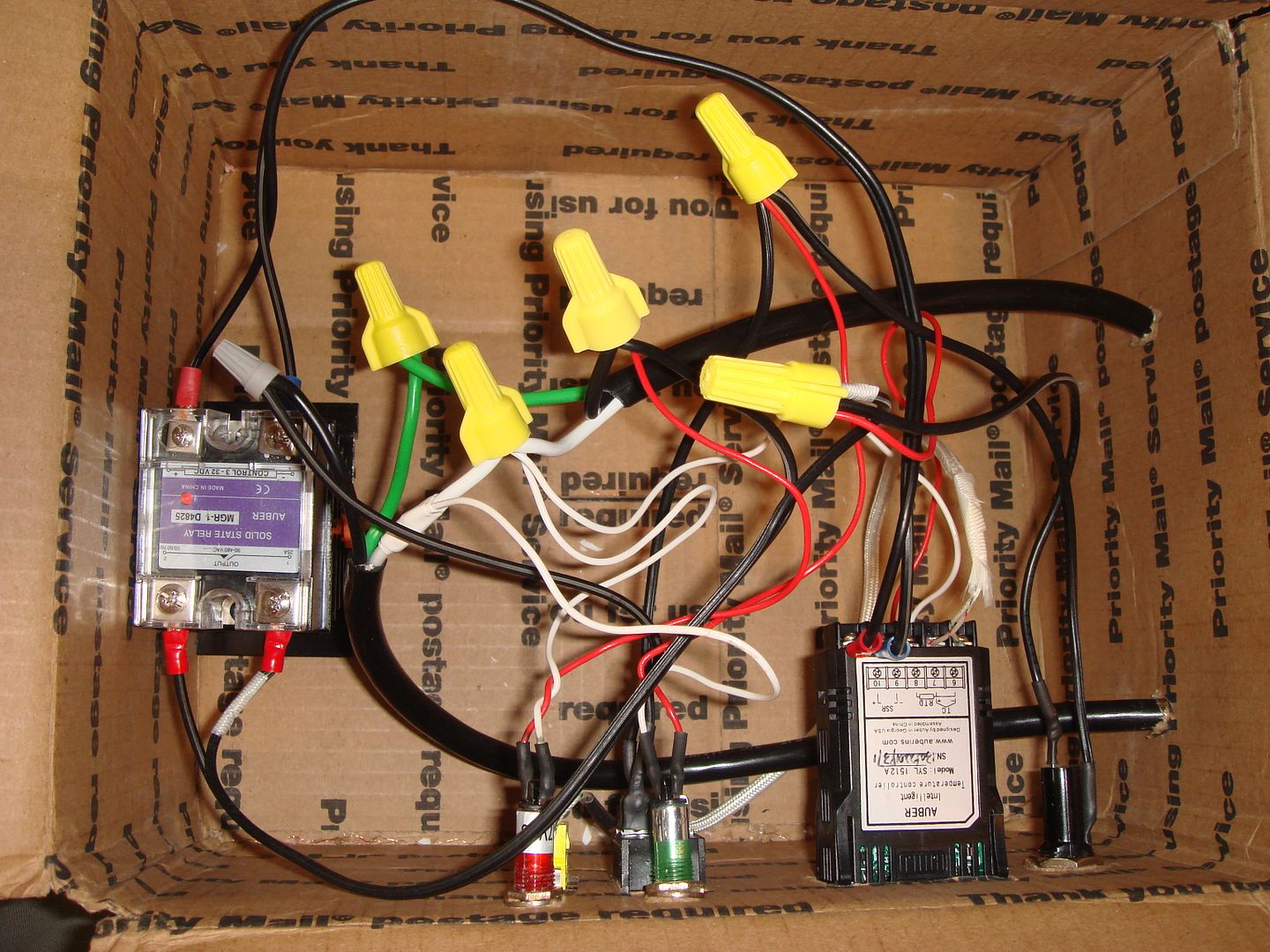

Ok if you see the white wires below. Moving from left to right in the top picture this post. One from each of the big cords are on the first terminal of the controller.

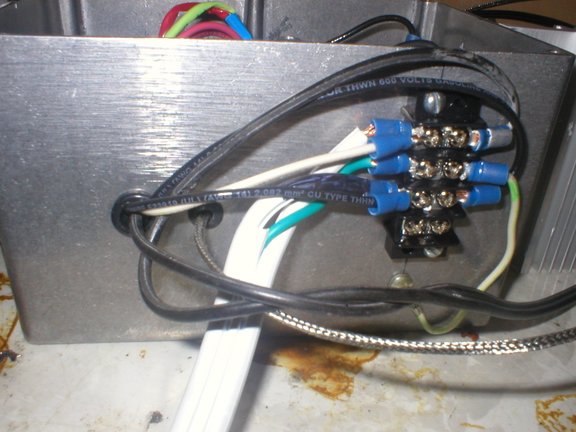

On the second terminal, there is the black from the male plug cord, and a white which goes out of the box and around to the top right terminal on the relay, which is shown in the bottom pic of the other post. ( I say top right. This is if your looking at it upright, if you follow me. Bottom Pic of top post.)

The black wires which are nutted together, one is from the female plug cord, the other one goes out the box and around to the top left terminal on the relay, opposite the white.

On the third terminal of the controller, is a black wire. It runs out of the box and attaches to the bottom left terminal of the relay.

On the fourth terminal of the controller, is the red wire. It goes out of the box and attaches to the bottom right terminal on the relay.

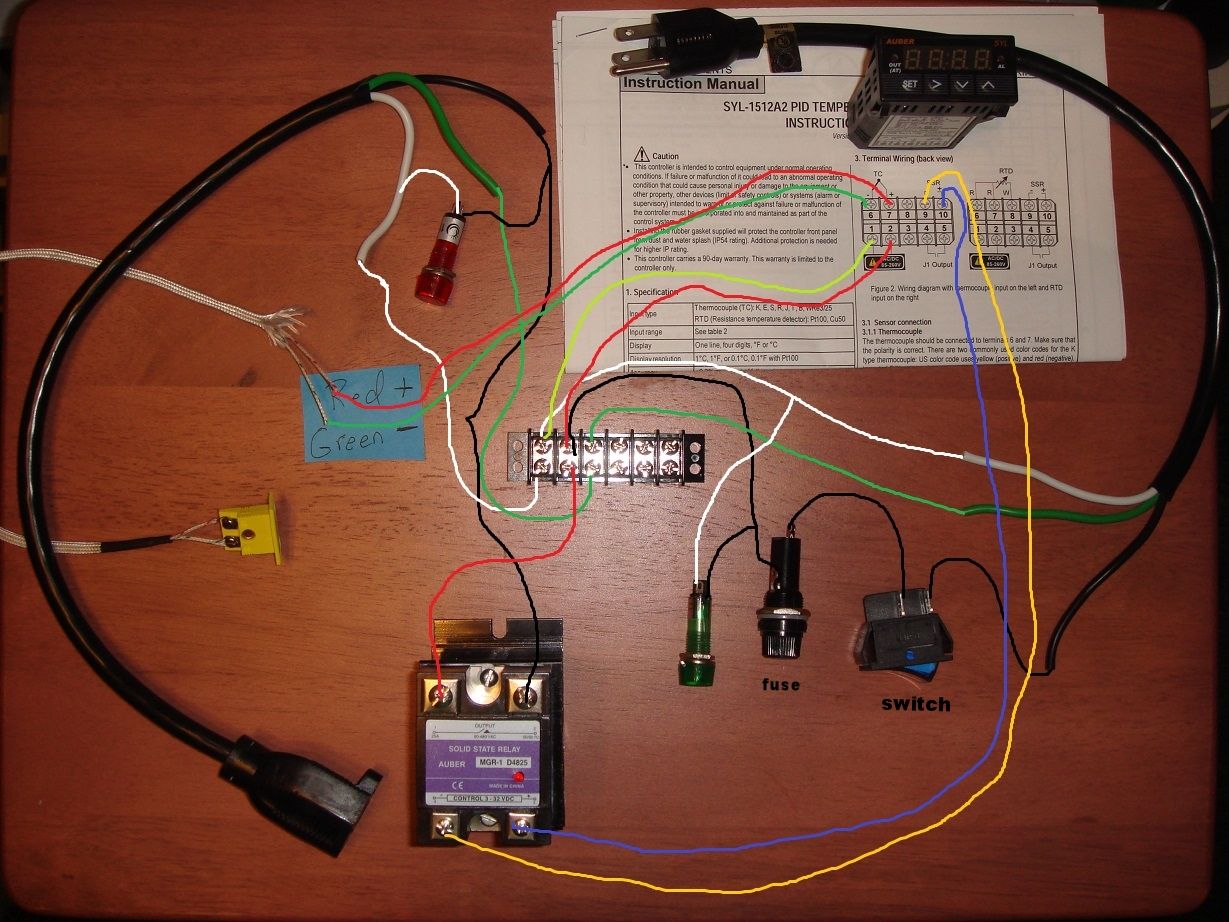

The RTD wires connect to the terminals #5 and 4 opposite side from the power wires.

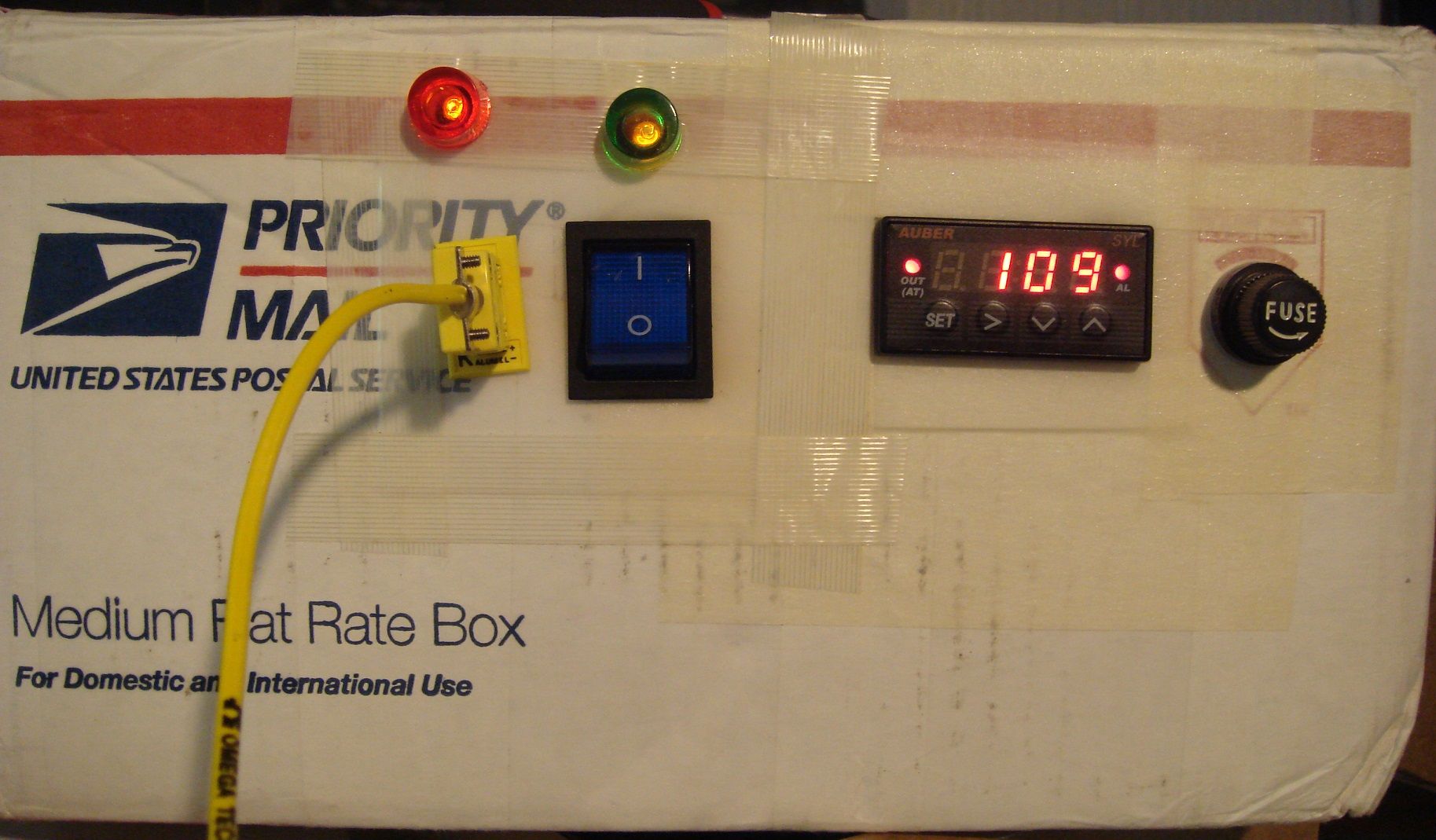

Ok about all those flashy lights and other stuff you have, well your on your own with those. As you see mine is pretty straight forward and simple. When the numbers are on, so is the power. I just like the KISS principle.

Now if I can get this one all put back together, and wire up the other one tomorrow, I will be all set to pour AND lube....

I believe I started collecting these parts sometime around last June and this is how far I've gotten.

I believe I started collecting these parts sometime around last June and this is how far I've gotten.