You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a Barrel.

- Thread starter DimitriS

- Start date

A little discussion on the subject here:

http://www.practicalmachinist.com/ubb/ultimatebb.php?ubb=get_topic;f=16;t=000631

Sam

http://www.practicalmachinist.com/ubb/ultimatebb.php?ubb=get_topic;f=16;t=000631

Sam

Harry Bonar

New member

making a barrel

Dear Sir:

Your enthusiasm is commendable. I would say that you can go to Douglas barrels in Charleston W.Va and they will give you a tour about the shop and every aspect of barrel making. I realize that is a long way from Canada but you're sure to find a barrel maker there who would help you, in Canada.

In the Modern Gunsmith by J.V. Howe he tells of a man in the canadian wilderness who made a barrel from raw materials and it shot!

The old mountain gunsmiths made barrels for their muzzle-loaders under trees, in the woods, at forges, under every hindrance - and more accurate barrels have NEVER been made!

Harry B.

Dear Sir:

Your enthusiasm is commendable. I would say that you can go to Douglas barrels in Charleston W.Va and they will give you a tour about the shop and every aspect of barrel making. I realize that is a long way from Canada but you're sure to find a barrel maker there who would help you, in Canada.

In the Modern Gunsmith by J.V. Howe he tells of a man in the canadian wilderness who made a barrel from raw materials and it shot!

The old mountain gunsmiths made barrels for their muzzle-loaders under trees, in the woods, at forges, under every hindrance - and more accurate barrels have NEVER been made!

Harry B.

Harry,

Thanks for the reply

Douglas isnt too far if it means I can get a better understanding and refine my design before I make it. Might make the trip if I got myself some spare time and money just before I get started.

I dont belive there are any barrel makers in Canada. As a matter of fact I only know of 2 firearms companies in the whole country (Para-Ord and Demaco now owned by Colt).

Its cost verse cost. This is a personal project I dont ever execpt to get my money back from my machine. If visiting Douglas or any other barrel maker will help me spend less pocket money because I'm not just reading/thinking how your supposed to do it then its all the better

Dimitri

Thanks for the reply

Douglas isnt too far if it means I can get a better understanding and refine my design before I make it. Might make the trip if I got myself some spare time and money just before I get started.

I dont belive there are any barrel makers in Canada. As a matter of fact I only know of 2 firearms companies in the whole country (Para-Ord and Demaco now owned by Colt).

Its cost verse cost. This is a personal project I dont ever execpt to get my money back from my machine. If visiting Douglas or any other barrel maker will help me spend less pocket money because I'm not just reading/thinking how your supposed to do it then its all the better

Dimitri

Dimitri,

I don't see any problem with your idea in principle. For drilling and reaming, controlling the feeds rates with stepper motors is basic NC machining. I'm not sure you even need a microprocessor if you are dedicating the machine to barrel making? Controllers for stepper motors are available or you can make them, so you just need to generate pulses to the motor drives at the right speeds and ratios. Basic clock and programmable dividers could do that as well as could a micro. The interface could just be mechanical switches in either case.

The rifling is a little different. Unlike the drilling, where it doesn't matter if one of the stepper motors drops a phase from time to time, you need absolute position information to align the cutter for each pass. I built a scanning X-ray densitometer interface in the early 80's that did these basic functions. It used shaft angle encoders, counters, and registers to buffer I/O for a computer bus (PDP 11, if that tells you how old the gear was - 2 mb disk cart the size of a stack of pizzas) and to recieve locating information and move the stepper. A rotating glass drum held the X-ray while a stepper on a lead screw drove a mechanically linked light source and sensor pair along opposite sides of the glass.

So, yes it is all doable. Something to think about. If big steppers are used for both indexting the blank and for running the lead screw, it is not inconceivable one machine would serve both to drill and ream as well as to cut rifling. For the small shop, that would be advantageous. It would also minimize setup and alignment problems. Interesting to consider.

Nick

I don't see any problem with your idea in principle. For drilling and reaming, controlling the feeds rates with stepper motors is basic NC machining. I'm not sure you even need a microprocessor if you are dedicating the machine to barrel making? Controllers for stepper motors are available or you can make them, so you just need to generate pulses to the motor drives at the right speeds and ratios. Basic clock and programmable dividers could do that as well as could a micro. The interface could just be mechanical switches in either case.

The rifling is a little different. Unlike the drilling, where it doesn't matter if one of the stepper motors drops a phase from time to time, you need absolute position information to align the cutter for each pass. I built a scanning X-ray densitometer interface in the early 80's that did these basic functions. It used shaft angle encoders, counters, and registers to buffer I/O for a computer bus (PDP 11, if that tells you how old the gear was - 2 mb disk cart the size of a stack of pizzas) and to recieve locating information and move the stepper. A rotating glass drum held the X-ray while a stepper on a lead screw drove a mechanically linked light source and sensor pair along opposite sides of the glass.

So, yes it is all doable. Something to think about. If big steppers are used for both indexting the blank and for running the lead screw, it is not inconceivable one machine would serve both to drill and ream as well as to cut rifling. For the small shop, that would be advantageous. It would also minimize setup and alignment problems. Interesting to consider.

Nick

Nick,

Thats what I was thinking

The Microcontroller is basiclly a 8-bit computer that is all on one chip used for automating things. I have delt with them before and I know how to use them so I basiclly will do what you said execpt I wanted it to be one button control.

Basiclly in a layed out plan it will work like this:

-> Button pressed

-> Microcontroller interprets

-> Microcontroller controls the motor controllers to provid ether proper drilling speeds or rifling speeds

-> Controller controls the motor as derected by the Microcontroller.

It shouldnt be too hard as you said in principle.

Whats funny is that the single microcontroller can do everything the whole computer you had in the 80's on one chip and without resortign to using pizza sized disks.

I'm gonna button rifle so all the rifling cuts are made at the same time. It shouldnt matter too much execpt it might mean slight differences in the rifling from barrel to barrel but then agian it shouldnt matter too much

I'm gonna button rifle so all the rifling cuts are made at the same time. It shouldnt matter too much execpt it might mean slight differences in the rifling from barrel to barrel but then agian it shouldnt matter too much

Nick What do you think ??

Dimitri

Thats what I was thinking

The Microcontroller is basiclly a 8-bit computer that is all on one chip used for automating things. I have delt with them before and I know how to use them so I basiclly will do what you said execpt I wanted it to be one button control.

Basiclly in a layed out plan it will work like this:

-> Button pressed

-> Microcontroller interprets

-> Microcontroller controls the motor controllers to provid ether proper drilling speeds or rifling speeds

-> Controller controls the motor as derected by the Microcontroller.

It shouldnt be too hard as you said in principle.

Whats funny is that the single microcontroller can do everything the whole computer you had in the 80's on one chip and without resortign to using pizza sized disks.

Wouldnt I only need to worry about this when dealing with cut rifling ??The rifling is a little different. Unlike the drilling, where it doesn't matter if one of the stepper motors drops a phase from time to time, you need absolute position information to align the cutter for each pass.

Nick What do you think ??

Dimitri

Yeah. I'd forgotten you were going to button rifle. I was thinking of the cut rifling because of the video tapes and machinist site link discussed earlier.

I was trying to work out a way for a single machine to drill and ream and run the rifling cutter all without removing the barrel blank from its chuck. In principle it can be done. In practice there are some awkward elements. Be an interesting challenge, though.

Nick

I was trying to work out a way for a single machine to drill and ream and run the rifling cutter all without removing the barrel blank from its chuck. In principle it can be done. In practice there are some awkward elements. Be an interesting challenge, though.

Nick

Nick,

I've since edited my design. Thanks for all the help guys! You've been great so far and a fountain of knowlage and ideas.

I basiclly just modified it slightly and the barrel does stay in the machine the whole time. Doesnt get chambered or chamber reamed in the machine though. I designed a little benchtop unit for that.

All you need to do is install the gun drill bit, press a button, install the reamer press a button, install the button, press a button. Not too hard I dont think

I dont got a machine shop now and I'm still in college for Tool and Die so wont start this project for atleast another 2 years. But 2 years is like nothing for me I have a bad sense of days/weeks/months

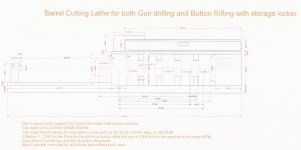

Tell me Nick, how does this refined version look ?? ITs not as complicated in the layout. And I edited what part the barrel goes in. Now the barrel supports lock in the barrel and it also turns it.

ITs not as complicated in the layout. And I edited what part the barrel goes in. Now the barrel supports lock in the barrel and it also turns it.

The metal stock used would be 35inchs long, It should be able to cut up to 27.5 inch barrels (to cover most lenghts) eaisly but if you did 2 cuts I'd imagine you could make a 35inch for a 50BMG or 30ish inch for barrels that are long action rounds.

So you'd drill out the barrel and then make the chamber if you wanted a really long one. Its a option if needed without really adding to the cost/size of the machine. I wouldnt do it though.

Dimitri

I've since edited my design. Thanks for all the help guys! You've been great so far and a fountain of knowlage and ideas.

I basiclly just modified it slightly and the barrel does stay in the machine the whole time. Doesnt get chambered or chamber reamed in the machine though. I designed a little benchtop unit for that.

All you need to do is install the gun drill bit, press a button, install the reamer press a button, install the button, press a button. Not too hard I dont think

I dont got a machine shop now and I'm still in college for Tool and Die so wont start this project for atleast another 2 years. But 2 years is like nothing for me I have a bad sense of days/weeks/months

Tell me Nick, how does this refined version look ??

The metal stock used would be 35inchs long, It should be able to cut up to 27.5 inch barrels (to cover most lenghts) eaisly but if you did 2 cuts I'd imagine you could make a 35inch for a 50BMG or 30ish inch for barrels that are long action rounds.

So you'd drill out the barrel and then make the chamber if you wanted a really long one. Its a option if needed without really adding to the cost/size of the machine. I wouldnt do it though.

Dimitri

Attachments

Harry Bonar

New member

making bbl.

Hey Guys:

You're ALL beyond this old boy!

Harry B.

Hey Guys:

You're ALL beyond this old boy!

Harry B.

Harry Bonar,

No your not Its simple 101 machining. We just made it complicated by trying to make a machine to do it automaticly for us instead of doing it all by hand.

Its simple 101 machining. We just made it complicated by trying to make a machine to do it automaticly for us instead of doing it all by hand.

PS. Without the "old boys" new guys like me wouldnt know what to do! Everything is built on something that was aready made.

Dimitri

No your not

PS. Without the "old boys" new guys like me wouldnt know what to do! Everything is built on something that was aready made.

Dimitri

If you are button broaching, which is a form of swaging, I'm 99% sure the shape of the button controls the twist rate. The button is pulled through the gundrilled blank, and is allowed to spin on its arbor. A large hydraulic cylinder is used to pull the button through the barrel. The hard part is getting the right shape for the button.

For the gundrilling, get the highest pressure oil pump you can afford. It makes all the diference in the world. Don't peck gundrills. It screws up the self-made bushing. 1000 psi - 100 gal/min would not be out of line. Make sure its easy to replace the drill bushing in the machine.

Cut broach rifling is probably not practical for a rifle barrel. The tool has to be as long as the barrel, and will probably cost in excess of $30K. You do have to control the twist rate externally.

Electrochemical machining is pretty slick, and would let you continue to play with your servos, in addition to letting you play with funky power supplies.

For the gundrilling, get the highest pressure oil pump you can afford. It makes all the diference in the world. Don't peck gundrills. It screws up the self-made bushing. 1000 psi - 100 gal/min would not be out of line. Make sure its easy to replace the drill bushing in the machine.

Cut broach rifling is probably not practical for a rifle barrel. The tool has to be as long as the barrel, and will probably cost in excess of $30K. You do have to control the twist rate externally.

Electrochemical machining is pretty slick, and would let you continue to play with your servos, in addition to letting you play with funky power supplies.

I'd like to add that it is usually easier to spin the part than it is to spin the tool. Especially when you are gun drilling, that high pressure oil can be hard to seal up.

Why are you using square bar?

I think you would be better off trying to rebuild an old engine lathe to do this.

Why are you using square bar?

I think you would be better off trying to rebuild an old engine lathe to do this.

BIGJACK,

I'm not gonna start this project till after college. Need to learn all I can in college to understand how to do this well College and learning what I need to right now is going great I understand it all 100% I bet I could take my exams and pass at this point thanks to reading everything in advance

College and learning what I need to right now is going great I understand it all 100% I bet I could take my exams and pass at this point thanks to reading everything in advance

owen,

Thanks for all the tips And as for using bar stock is just to have a little more metal on the stock when I'm drilling and rifling so I dont bend the barrel or something while drilling, I figured the more metal the better.

And as for using bar stock is just to have a little more metal on the stock when I'm drilling and rifling so I dont bend the barrel or something while drilling, I figured the more metal the better.  Plus its not like I couldnt simply just cut it to the proper contour on a lathe afterwards

Plus its not like I couldnt simply just cut it to the proper contour on a lathe afterwards

Dimitri

I'm not gonna start this project till after college. Need to learn all I can in college to understand how to do this well

owen,

Thanks for all the tips

Dimitri