You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a Barrel.

- Thread starter DimitriS

- Start date

HSMITH,

LOL I dont want a CNC machine to do it. Actually I've been using DesignCAD to draw up a machine that can do it automaticlly.

Not really CNC per say. It would run off a microcontroller to control the rate the one motor turns the barstock and control the other motor to "push" the stock at the right speed through to make different rifle twists.

The machine I "invision" will be 88.5 inches long and can handle up to 31 inch barrel assuming I'm making a 300RUM or similar length chambering.

and can handle up to 31 inch barrel assuming I'm making a 300RUM or similar length chambering.

This is all assuming the machine will work (I think I could get all to work after a few test barrels) and I can get all the parts for it.

What do you think ??

Dimitri

LOL I dont want a CNC machine to do it. Actually I've been using DesignCAD to draw up a machine that can do it automaticlly.

Not really CNC per say. It would run off a microcontroller to control the rate the one motor turns the barstock and control the other motor to "push" the stock at the right speed through to make different rifle twists.

The machine I "invision" will be 88.5 inches long

This is all assuming the machine will work (I think I could get all to work after a few test barrels) and I can get all the parts for it.

What do you think ??

Dimitri

I think using a motor to control the stock turning is going to need a gear reduction and/or a transmission to control output speed. It would take a MASSIVE motor to have the power needed at the very low speeds the barrel will need to be turning at without reduction.

If you are looking at single point cut rifling you will need a way to index the barrel or cutter accurately for each cut. If you are looking at button rifling you will need a LOT of power to pull it through the barrel.

I think pushing the stock is the wrong way to do it, the bit size is going to be small and long, like pushing a rope up a hill. I think you need to pull the tool through the stock.

You will also need to gundrill the barrel blanks relatively straight and control the size closely before even going into the rifling process.

Just a few opinions, hope it helps.

If you are looking at single point cut rifling you will need a way to index the barrel or cutter accurately for each cut. If you are looking at button rifling you will need a LOT of power to pull it through the barrel.

I think pushing the stock is the wrong way to do it, the bit size is going to be small and long, like pushing a rope up a hill. I think you need to pull the tool through the stock.

You will also need to gundrill the barrel blanks relatively straight and control the size closely before even going into the rifling process.

Just a few opinions, hope it helps.

HSMITH,

Thanks for the information so far

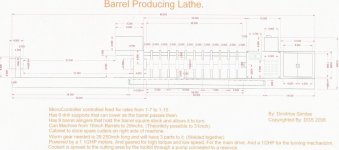

I'm not sure how this would be done but here is a picture of my "vision" of a working machine attached here.

What do you think ??

Its Button rifling I think. The cutter makes all of the cuts on the same pass and it does the cutting by having the machine push the metal into the cutter and it has a seperate motor to do the turing.

Dimitri

Thanks for the information so far

I'm not sure how this would be done but here is a picture of my "vision" of a working machine attached here.

What do you think ??

Its Button rifling I think. The cutter makes all of the cuts on the same pass and it does the cutting by having the machine push the metal into the cutter and it has a seperate motor to do the turing.

Dimitri

Attachments

I still think you are pushing a rope up the hill trying to push the stock over the button. Once the supports drop away the entire rod length that is in the bore will be unsupported in the bore, and it will bend and rub on the barrel bore best case. Worst case, and what I suspect will happen is that the bit will break. Pulling it through greatly simplifies the machine as well as alignment of the stock to the bit.

HSMITH,

Yah I guess I'm not sure though how you would make a machine that could pull it through

I understand what your saying to pulling it through but I'm really unsure how I'd do it. In my mind it somehow seems simplier pushing a large square stock then pulling a thin rod.

Maybe put rubber padding on the rod to make it stable in the barrel ??

I'll take any advice you give I can really use it as I dont know much about barrel making execpt from a couple articals I've read.

Dimitri

Yah I guess I'm not sure though how you would make a machine that could pull it through

I understand what your saying to pulling it through but I'm really unsure how I'd do it. In my mind it somehow seems simplier pushing a large square stock then pulling a thin rod.

Maybe put rubber padding on the rod to make it stable in the barrel ??

I'll take any advice you give I can really use it as I dont know much about barrel making execpt from a couple articals I've read.

Dimitri

For simplicity I would make the rod with a ring or flats that a setscrew/s could engage to couple the rod to the traveling part of the machine. The same mechanism you are using to traverse the stock should work to traverse the tooling.

I am a big fan of the KISS method. If I were going to do it I would probably make the machine with hydraulic rams to pull the tooling through. I would rotate the tooling through a stationary blank by using a rack and pinion, the rack would be stationary and the pinion would be on the travelling part. The pinion would drive two more gears between it and the ring gear on the rotating 'chuck' that will hold the tooling. Swapping out the two gears in between would let me change the twist rate easily, and from the little thought I have put in it would be extremely repeatable and accurate.

My experience is all CNC, but with a lot of deep hole work. I wonder what actual barrel making machinery looks like........

I am a big fan of the KISS method. If I were going to do it I would probably make the machine with hydraulic rams to pull the tooling through. I would rotate the tooling through a stationary blank by using a rack and pinion, the rack would be stationary and the pinion would be on the travelling part. The pinion would drive two more gears between it and the ring gear on the rotating 'chuck' that will hold the tooling. Swapping out the two gears in between would let me change the twist rate easily, and from the little thought I have put in it would be extremely repeatable and accurate.

My experience is all CNC, but with a lot of deep hole work. I wonder what actual barrel making machinery looks like........

GunTec TV, sponsored by MidWay USA, has had a few segments on barrel making. They always seem to start off with 12' bar stock in varying diameters and steel types. Seems they rough-cut the bore first with, essentially, a really long drill. Then, as HSMITH said, they pull a reamer through to get the final dimensions... In all of the segments i've seen, the stock rotates and the cutting head is stationary.

In the three factories i've seen, they all use a button to rifle the barrel.

One thing they showed at Schilen is they 'de-stress' the barrels by heating them up to something like 800-1200 degrees and let them sit for a bit. They do this once after the initial cutting, and once after the rifling. In at least the latter case, they pump in nitrogen to displace all of the oxygen to avoid oxidation. I don't think this does anything for the accuracy of a cold barrel, but i think it does help improve the accuracy as the barrel heats up.

I haven't seen anyone cut rifling yet (although i had seen mention of a manufacturer using EDM to cut it...just haven't seen it on TV or anything)

Edit: Just found this...for airguns, but you may get some ideas:

http://www.quackenbushairguns.com/Airgun_barrels.htmhttp://www.quackenbushairguns.com/Airgun_barrels.htm

In the three factories i've seen, they all use a button to rifle the barrel.

One thing they showed at Schilen is they 'de-stress' the barrels by heating them up to something like 800-1200 degrees and let them sit for a bit. They do this once after the initial cutting, and once after the rifling. In at least the latter case, they pump in nitrogen to displace all of the oxygen to avoid oxidation. I don't think this does anything for the accuracy of a cold barrel, but i think it does help improve the accuracy as the barrel heats up.

I haven't seen anyone cut rifling yet (although i had seen mention of a manufacturer using EDM to cut it...just haven't seen it on TV or anything)

Edit: Just found this...for airguns, but you may get some ideas:

http://www.quackenbushairguns.com/Airgun_barrels.htmhttp://www.quackenbushairguns.com/Airgun_barrels.htm

Last edited:

Thanks for the replys

HSMITH,

How did you do deep hole drilling ??

So what your telling me is that I should rework my idea to have the bar stock connected to where the drill bit is and instead of pushing the metal I should pull the metal ?? If so I'll think of a good way to do that

jcims,

Yup the cutting head is stationary thats why I was planning on doing it this way but pulling the bit and rotating the stock makes sense after all since everywhere I've read about button rifling which is what I'm planning on doing says they do pull the "button"

Dimitri

HSMITH,

How did you do deep hole drilling ??

So what your telling me is that I should rework my idea to have the bar stock connected to where the drill bit is and instead of pushing the metal I should pull the metal ?? If so I'll think of a good way to do that

jcims,

Yup the cutting head is stationary thats why I was planning on doing it this way but pulling the bit and rotating the stock makes sense after all since everywhere I've read about button rifling which is what I'm planning on doing says they do pull the "button"

Dimitri

How many thousand barrels are you planning to make?

The reason I ask is that the expense of making a machine to do it all in 1 trick is really steep. Not economical at all unles you are making several thousand and preferable sevral hundred thousand.

On the other hand you can drill a barrel in several ways (or not drill at all sometimes) and you can make a rifling machine at home for next to nothing.

Only 2 pieces of metal required other than fasteners.

Sam

The reason I ask is that the expense of making a machine to do it all in 1 trick is really steep. Not economical at all unles you are making several thousand and preferable sevral hundred thousand.

On the other hand you can drill a barrel in several ways (or not drill at all sometimes) and you can make a rifling machine at home for next to nothing.

Only 2 pieces of metal required other than fasteners.

Sam

Sam,

I'm planning on making maybe 10 barrels or so

Its for a learning experiance more or less. And who knows if it works out all right I might make it a small bussince for cheap barrels for all of thouse surplus guns when buying and installing a barrel in it for 200$ isnt worth it

My machine that I posted up there could only handle one barrel at a time and it wont cost a million plus .... mayabe up to a thousand dollars assuming I build and rebuild it alot and work out all the bugs 100% in the system to make if I dont count my time because it will be like a hobby thing for me

Dimitri

I'm planning on making maybe 10 barrels or so

Its for a learning experiance more or less. And who knows if it works out all right I might make it a small bussince for cheap barrels for all of thouse surplus guns when buying and installing a barrel in it for 200$ isnt worth it

My machine that I posted up there could only handle one barrel at a time and it wont cost a million plus .... mayabe up to a thousand dollars assuming I build and rebuild it alot and work out all the bugs 100% in the system to make if I dont count my time because it will be like a hobby thing for me

Dimitri

DmitriS,

For that number I would drill them on a lathe and cut rifle by hand.

I couldn't describe how to make a hand rifling machine but would insted suggest that you purchase a copy of the "Foxfire Book vol 5" which has instructions and some dimensioned drawings to make arifling machine.

If you wanted to go "by the book' you could make a barrel from horsehoe nail scraps.

Rifling a drilled barrel is identical to rifling a forge welded muzzle loader barrel and the book will show you everything you need.

Sam

For that number I would drill them on a lathe and cut rifle by hand.

I couldn't describe how to make a hand rifling machine but would insted suggest that you purchase a copy of the "Foxfire Book vol 5" which has instructions and some dimensioned drawings to make arifling machine.

If you wanted to go "by the book' you could make a barrel from horsehoe nail scraps.

Rifling a drilled barrel is identical to rifling a forge welded muzzle loader barrel and the book will show you everything you need.

Sam

Sam,

I understand what your saying about cost verses benifits but this is more of something I want to do as a hobby then anything else

And I'll look that book up at the bookstore I aready bought 600$ worth of books this month another one wont hurt.

I aready bought 600$ worth of books this month another one wont hurt.  (College books but still

(College books but still  )

)

Sam I got to ask you do realize if the drillbit is turning when your doing the cutting it will wobble too much ?? Thats why barrel companies have the metal do the turning/moving not the drill bit. And with a large 50+ caliber barrel you can have a pretty thick drill bit allowing you to turn it but with a 300cal barrel its too small to turn the drillbit

Dimitri

I understand what your saying about cost verses benifits but this is more of something I want to do as a hobby then anything else

And I'll look that book up at the bookstore

Sam I got to ask you do realize if the drillbit is turning when your doing the cutting it will wobble too much ?? Thats why barrel companies have the metal do the turning/moving not the drill bit. And with a large 50+ caliber barrel you can have a pretty thick drill bit allowing you to turn it but with a 300cal barrel its too small to turn the drillbit

Dimitri

Dimitri,

You might want to take a look at this 3-hour video on building a rifled barrel machine sold by a fellow Canadian, Guy Lautard:

http://lautard.com/rmv.htm

You might want to take a look at this 3-hour video on building a rifled barrel machine sold by a fellow Canadian, Guy Lautard:

http://lautard.com/rmv.htm

Don,

If you're at all familiar with machines, yes they contain enough information. Their purpose is to show how to make and use such a machine. They modify an existing lathe.

If you are not familiar with basic machinery, you can do worse than to get the late David Gingery's series on how he built a machine shop from scratch over a 20 year period; starting with the casting foundry. He takes some shortcuts, like using allthread for a master lead screw (not recommended), but you can learn quite a bit about how these things work and go together. Lindsay books had them when I last looked.

As to whether it is worth it? If you like doing things yourself, it can be. Would it be economical? Depends on how well you can scrounge and how many barrels you intend to make? The old lathe to serve as the base machine can set you back the cost of a number of barrels. By the time you buy good quality steel billets for making your own and ammortize the machinery over the number of barrels you intend to make, the savings may not be better than just buying finished barrel blanks from Douglas. Plus, you are still going to need a conventional lathe for chambering. So you are into some space and equipment before you are finished.

I settled for having a conventional lathe and buying rough-contoured blanks.

Nick

If you're at all familiar with machines, yes they contain enough information. Their purpose is to show how to make and use such a machine. They modify an existing lathe.

If you are not familiar with basic machinery, you can do worse than to get the late David Gingery's series on how he built a machine shop from scratch over a 20 year period; starting with the casting foundry. He takes some shortcuts, like using allthread for a master lead screw (not recommended), but you can learn quite a bit about how these things work and go together. Lindsay books had them when I last looked.

As to whether it is worth it? If you like doing things yourself, it can be. Would it be economical? Depends on how well you can scrounge and how many barrels you intend to make? The old lathe to serve as the base machine can set you back the cost of a number of barrels. By the time you buy good quality steel billets for making your own and ammortize the machinery over the number of barrels you intend to make, the savings may not be better than just buying finished barrel blanks from Douglas. Plus, you are still going to need a conventional lathe for chambering. So you are into some space and equipment before you are finished.

I settled for having a conventional lathe and buying rough-contoured blanks.

Nick