You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M1 garand cracked receiver

- Thread starter bbman25

- Start date

Willie Sutton

Moderator

Really?

Thousands of welded up former dewat rifles are circulating and still selling.

Throw away an old soldier? Seems like a crime.

This isn't even close to the splicing of two cut off receivers that was a common practice in years gone by. I guess buying two dozen Garands does not bring with it history lesson of how Garands first came to be owned here by civilians. Hint: They were all spliced together from two halves long before there was TIG welding. Nope... they were just ordinary stick welds followed up with a surface grinder.

Willie

.

Thousands of welded up former dewat rifles are circulating and still selling.

Throw away an old soldier? Seems like a crime.

This isn't even close to the splicing of two cut off receivers that was a common practice in years gone by. I guess buying two dozen Garands does not bring with it history lesson of how Garands first came to be owned here by civilians. Hint: They were all spliced together from two halves long before there was TIG welding. Nope... they were just ordinary stick welds followed up with a surface grinder.

Willie

.

M1 Rifle

Too little information.

bbman25, was this rifle from the CMP/DCM? What powder did the reloader use, how much and what weight bullet?

The receiver may have been a weld-up already? And lead dipping to anneal the heels of some receiver was a practice at Springfield during war production.

My personal opinion is that I treasure my boyish good looks too much to have them ruined by and exploding rifle.

As stated by some of the others. Salvage the undamaged parts and go to the CMP to buy a Field or Rack Grade M1.

Too little information.

bbman25, was this rifle from the CMP/DCM? What powder did the reloader use, how much and what weight bullet?

The receiver may have been a weld-up already? And lead dipping to anneal the heels of some receiver was a practice at Springfield during war production.

My personal opinion is that I treasure my boyish good looks too much to have them ruined by and exploding rifle.

As stated by some of the others. Salvage the undamaged parts and go to the CMP to buy a Field or Rack Grade M1.

Well, some of those "cut and weld" receivers did crack at the welds, no matter what anyone says. The location of the weld meant that none (AFIAK) caused any injury or catastrophic failure of the receiver, but to say that none ever cracked is not true.

The receiver heel is not intended to stop op rod travel; that is done at the front of the receiver. The heel allows a place for the bolt to stop when play between the op rod and the bolt allows the bolt to keep moving after the op rod stops. Normally, there is little force applied at that point, but the heels did crack (just like that) when firing rifle grenades before they developed the valve type gas cylinder lock screw and the grenade launchers that open the valve. Subsequently, the heels of new receivers were annealed in molten lead, and some were annealed during rebuilds; probably that one was not treated.

I guess I am on the fence on this one. I agree that continued firing of the rifle is unlikely to cause any further problem, even if the cracks are not welded, and that welding them will do no harm. Yet, on general principles, I don't like the idea of continued use of that receiver unless absolutely necessary. It is not a matter of life or death, of needing the rifle to defend home and homeland, and there are other M1 rifles available at reasonable cost.

Jim

The receiver heel is not intended to stop op rod travel; that is done at the front of the receiver. The heel allows a place for the bolt to stop when play between the op rod and the bolt allows the bolt to keep moving after the op rod stops. Normally, there is little force applied at that point, but the heels did crack (just like that) when firing rifle grenades before they developed the valve type gas cylinder lock screw and the grenade launchers that open the valve. Subsequently, the heels of new receivers were annealed in molten lead, and some were annealed during rebuilds; probably that one was not treated.

I guess I am on the fence on this one. I agree that continued firing of the rifle is unlikely to cause any further problem, even if the cracks are not welded, and that welding them will do no harm. Yet, on general principles, I don't like the idea of continued use of that receiver unless absolutely necessary. It is not a matter of life or death, of needing the rifle to defend home and homeland, and there are other M1 rifles available at reasonable cost.

Jim

so about.. 2 and a half months ago a buddy and i were shooting the garand at the range. we were shooting reloads that my grampa and i made, he is an experienced reloader and has been doing this since the 60s. i have a 1942 manufacture spiringfield garand. anyway, about 5 rounds in, i pulled the trigger and heard 2 rounds go off. there was only 7 cases on the ground, for a short time we couldnt even find the missing case or any evidence of it. when we did find it, the neck was all ballooned out, and the case looked like a giant .45. so we are assuming what had happened was the round went off as it was being chambered, and we have no idea why. luckily the bullet left the barrel and i only got minor powder burns on my neck..

An experienced reloader and an experienced gas gunner reloader are two different things.

What you had is obviously an out of battery slamfire. That cartridge likely had a sensitive primer and it is highly probable that Grandpa’s reloads were too long or too fat.

The Garand has a free floating firing pin, like this M1 carbine. The M1 Carbine and the M1 Garand have a firing pin retraction cam. This cam pulls the firing pin back during extraction. It also has limited utility as a safety device, but is easily defeated by tight or long rounds. If your round was smaller than the chamber the odds would have been in your favor to have an in battery slamfire.

Only at final cam down is the firing pin retracted. Up to then the firing pin is totally free floating and tapping the heck out of the primer.

This is a M1 Carbine firing pin retraction cam.

This is the M1 Garand firing pin retraction cam they are functionally identical, just the carbine is easier to visually understand.

These are M1 Garand receivers and the firing pin is fully forward and just touching the firing pin retraction cam. As you can see there is only thousand's of an inch of forward movement left in bolt cam down and yet the firing pin is out about 0.064" of the bolt face.

This is most likely where your sensitive primer went off. Before lug engagement.

If the bolt has to stop here to crunch fit a long case or a fat case that firing pin is rebounding off the back of the primer at its highest velocity in its forward travel.

That is why it is important to small base size cases used in these rifles and to set up the dies with a case gage and size to gage minimum. This will reduce the risk of an out of battery slamfire.

I am curious to know if Grandpa used federal primers. Federal primers are the most sensitive primer on the market and the most "slamfiring" primer in Garands.

For these rifles it is safety critical to ream primer pockets to depth, seat the primers by hand, and verify that all of the primers are below the primer pocket. There is a chance that a cocked primer, with the anvil firmly seated on something, will cause a primer initiated slamfire. A high primer can cause a slamfire but only if the anvil is firmly seated. High primers are one of the most common cause of misfires because the primer won't fire unless the anvil is seated and is pushed up into the primer cake. However, given a shallow pocket it is theoretically possible that high primers could have done this.

Just examine the back of the ammunition you have and see if there are high or cocked primers.

It is also safety critical to use the least sensitive primer around because these rifles will slamfire in battery or worse, out of battery, given a sensitive enough primer.

I recommend CCI #34's and Tula7.62 primers as they considered "Mil Spec" primers. Which means they are less sensitive than commercial primers, federal being the most sensitive commercial primer on the market.

It is my considered opinion that Granda Pa's reloads cracked your receiver. It is also my considered opinion that your receiver cannot be repaired.

You are very fortunate that you did not lose an eye, or have wood fragments injure you.

Would you please post clear pictures of the blown case and the primer? The slamfire cases I have seen had clear firing pin indentations in the primer.

Last edited:

Willie Sutton

Moderator

Thanks Slamfire... well said and well written.

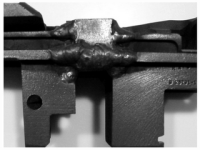

Attached is a photo of a REAL welding job on a receiver: Splicing together one from two pieces. Welds were then machined to remove excess metal, receivers refinished, and sold by the thousands post WW-II, as it was the only way to procure a Garand at the time. These turn up less frequently these days with all of the DCM and now CMP Garands available.

Willie

.

Attached is a photo of a REAL welding job on a receiver: Splicing together one from two pieces. Welds were then machined to remove excess metal, receivers refinished, and sold by the thousands post WW-II, as it was the only way to procure a Garand at the time. These turn up less frequently these days with all of the DCM and now CMP Garands available.

Willie

.

Attachments

Wille: That is ugly!

I really doubt anyone would recommend repairing a receiver cracked on the sidewalls or receiver heel.

The bolt comes back and rebounds off the receiver heel. The heel and sides have to withstand the impacts without cracking.

The few rewelds I have seen were joined in the middle. Thicker receiver section maybe easier to align.

I really doubt anyone would recommend repairing a receiver cracked on the sidewalls or receiver heel.

The bolt comes back and rebounds off the receiver heel. The heel and sides have to withstand the impacts without cracking.

The few rewelds I have seen were joined in the middle. Thicker receiver section maybe easier to align.

Willie Sutton

Moderator

Ugly is Ugly.. agreed. But this is how 1000's of them were spliced together in the old days, and how M-14 clones were made (chopping Garand receivers in half, shortening them, and re-welding) before M1's and then later M1A's were available.

Seems like a lot of work to get a rifle, but these things were not nearly as common in the 50's as they are now.

Today folks only weld things like Thompsons & Berettas back together.... (see attached)

Or MG-34's... (see attached as well)

Willie

.

Seems like a lot of work to get a rifle, but these things were not nearly as common in the 50's as they are now.

Today folks only weld things like Thompsons & Berettas back together.... (see attached)

Or MG-34's... (see attached as well)

Willie

.

Attachments

Last edited:

Willie Sutton

Moderator

I'm sure some of the spring-chester rewelds done back in the day cracked, but my understanding is that the biggest complaints were unreliable operation and inability to get predictable results from adjusting the sights.

Both problems related to lack of alignment between the rewelded halves.

If I squint, it looks like Willie's picture is an example of such misalignment.

Both problems related to lack of alignment between the rewelded halves.

If I squint, it looks like Willie's picture is an example of such misalignment.

the old gringo

Inactive

m1

do not weld big no no !!!! that is one of the best made weapons took a good bang to do that hang it on the wall contact the cmp and go again good luck

do not weld big no no !!!! that is one of the best made weapons took a good bang to do that hang it on the wall contact the cmp and go again good luck

You could get the parts you need directly from the CMP program if you are either a Member, Prior Military Service (and able to provide proof) or a member of a Gun Club that is on their list of Member clubs.

Here is a link directly to their M1 Garand Part listings.

http://odcmp.com/Sales/m1garand.htm

Edit: A striped receiver is $195 + shipping, a barreled Receiver with bolt is $350 plus shipping.

Here is a link directly to their M1 Garand Part listings.

http://odcmp.com/Sales/m1garand.htm

Edit: A striped receiver is $195 + shipping, a barreled Receiver with bolt is $350 plus shipping.

Looking at the cracks and having an understanding of modern welding equipment, methods, techniques of welding including heat-stop paste, heat sinks, post-welding re-heat treat, etc., I would opine that those cracks are indeed repairable. The finished product would be dependent upon the knowledge and skill of the welder. After all, that receiver started out as a red-hot piece of metal and the processes that produced a safe finished product can be reproduced after welding. Let us not run in circles shouting dire warnings of doom and a falling sky.Sir;

NEVER, NEVER, weld on any part of any rifle reciever!

Harry B.

Willie Sutton

Moderator

Thank You....

There's a bit of a difference between someone who views welding as the result of what their muffler shop does with a stick and a $69 plug into the wall AC "spark box" and the view of someone who understands the science of modern metal fusing.

Jet engine turbine blades are welded... but not by anyone at the muffler shop with an AC spark box...

What is impossible for one man is a lunchtime project for another.

Willie

.

There's a bit of a difference between someone who views welding as the result of what their muffler shop does with a stick and a $69 plug into the wall AC "spark box" and the view of someone who understands the science of modern metal fusing.

Jet engine turbine blades are welded... but not by anyone at the muffler shop with an AC spark box...

What is impossible for one man is a lunchtime project for another.

Willie

.

Well, with Slamfire claiming that those rifles blow up all over the place, scattering pieces across the landscape, and Willie Sutton wanting to weld the pieces back together, I guess it is time for the ignorant, unwashed like me to get out of here before Amsdorf sends us all to the Gulag for daring to call it an M1 instead of a Garand, the only term ever used by anyone ever, ever.

Jim

Jim

Cracked

Willie called it. That's the impact abutment for the bolt, and all the real stress is over by the time the bolt gets there. I think that a weld would hold it, and even if it fails...the rifle won't blow up.

Actually.... that receiver is not probably badly cracked enough to remove it from service. That's not a highly stressed area of the receiver

Willie called it. That's the impact abutment for the bolt, and all the real stress is over by the time the bolt gets there. I think that a weld would hold it, and even if it fails...the rifle won't blow up.

Even if that receiver was safe to fire with the existing cracks, from a purely aesthetic point of view, if the gun were mine, I would prefer a very neat MIG weldament bead or a welded and refinished area more than I could live with cracks. It is the compulsive repair person within me.

I guess it is time for the ignorant, unwashed like me to get out of here before Amsdorf sends us all to the Gulag for daring to call it an M1 instead of a Garand, the only term ever used by anyone ever, ever.

Jim

Interesting, the CMP refers to both the Garand and the Carbine as M1's and when I was growing up, many moons ago.. I remember going onto the various Military bases with my Dad and seeing men carrying the Garands and they were calling it an M1 . My Dad who was a Korean War vet carried an M1 Garand and not an M1 Carbine.

If you don't want to belive me that the proper term for it is really M1 Garand, check out:

http://odcmp.com/Sales/m1garand.htm

http://olive-drab.com/od_other_firearms_rifle_m1garand.php

http://en.wikipedia.org/wiki/M1_Garand