I am looking at getting a 308 rifle and am trying to make sure I understand things correctly before I take the dive. I already load 30-06 so I have a shell holder, primers, and bullets I can use with it.

I will be using 7.62x51 brass, as I was given decent sized batch for free, that is the main reason I am looking at the caliber.

As I understand it 308 and 7.62x51 have the same external dimension, so I can use regular 308 dies (although I did see 7.62x51 dies listed)

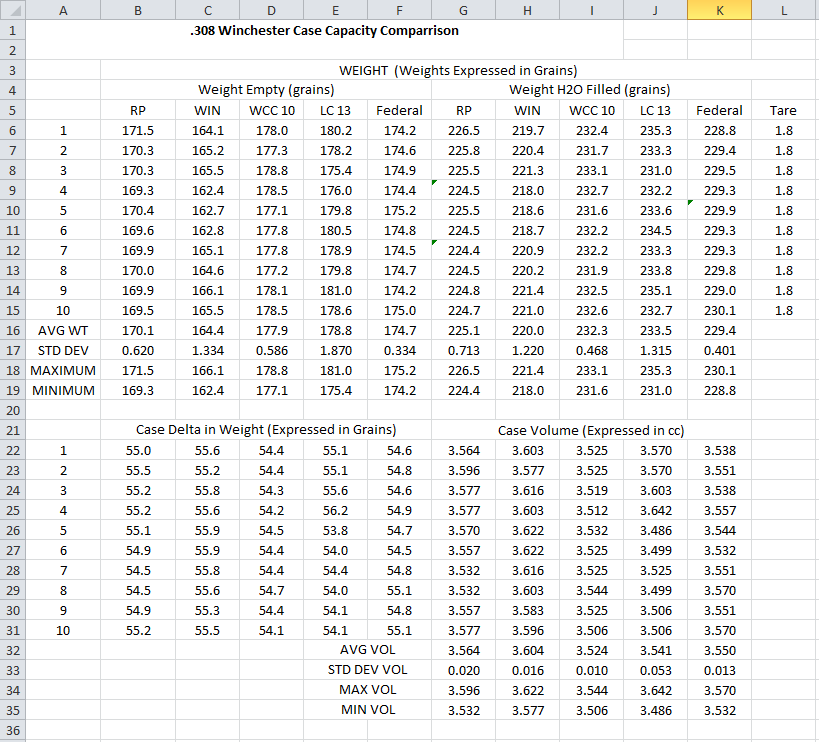

the 7.62x51 has thicker brass and less case capacity so I will need to be conservative working my loads up.

Does this sound about right? If so I just need to track down dies and a rifle. I really debated on this, but surplus rifles were big for a longtime because of cheap ammo. And already having a good bit of the tools and supplies makes it cheap for me. Was looking at the Ruger Americans.

I will be using 7.62x51 brass, as I was given decent sized batch for free, that is the main reason I am looking at the caliber.

As I understand it 308 and 7.62x51 have the same external dimension, so I can use regular 308 dies (although I did see 7.62x51 dies listed)

the 7.62x51 has thicker brass and less case capacity so I will need to be conservative working my loads up.

Does this sound about right? If so I just need to track down dies and a rifle. I really debated on this, but surplus rifles were big for a longtime because of cheap ammo. And already having a good bit of the tools and supplies makes it cheap for me. Was looking at the Ruger Americans.