You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lee Factory Crimp Die - Any advantage

- Thread starter kwm1971

- Start date

No, but some people may think you will need one. It doesn't matter to them that thousands of reloads without the FCD's use are excellent in all areas. I don't think any commercial or arsenal ammo's made using Lee's FCD. Both cases headspace on the case mouth so the FCD could cause problems.

Last edited:

polyphemus

New member

This die post sizes a round to a standard diameter and taper crimps it.Is there any need to get a factory crimp die for either caliber?

Some reloaders use only the sizing feature others remove the sizing ring and

only crimp cases with it.Some use both features and some don't even have one.A poster here in a previous thread on the same subject declared that the

FCD "changed his life".

So,you have to determine how you want to finish your product and then decide

whether you need this tool or not.

Smoke & Recoil

New member

I use the FCD only to fill the fourth hole in the 4-hole Lee Classic Turret, and

it gives meaning to the last station to look fulfilled...but most times, it's just

pretty in there.

it gives meaning to the last station to look fulfilled...but most times, it's just

pretty in there.

lee n. field

New member

I am currently reloading 9mm & 40SW rounds. I am using hardcast bullets & occasionally jacketed. I'm using Lee 3pc die sets. Is there any need to get a factory crimp die for either caliber?

maybe.

If your rounds feed and chamber right, 100% of the time, probably not.

This is the pistol type lee "carbide FCD", yes? (There are 2 types, one for pistol & another for rifle).

I find them useful, especially for plated bullets, but I'm using a revolver so we have different crimping needs. Mostly they are darn near impossible to over crimp with. That's an issue with plated bullets & roll crimps as its possible to cut the plating. Secondly they are more forgiving on case length variations. & finally they allow me to crimp & seat as separate functions, something I find useful with different bullet weights.

I find them useful, especially for plated bullets, but I'm using a revolver so we have different crimping needs. Mostly they are darn near impossible to over crimp with. That's an issue with plated bullets & roll crimps as its possible to cut the plating. Secondly they are more forgiving on case length variations. & finally they allow me to crimp & seat as separate functions, something I find useful with different bullet weights.

I used one for 223 and 308's. I pulled some bullets due to powder issues and was really surprised by the crimps on the FMJ's. I didn't realize how such a small roll on the case would dent the bullet so bad. If I crimp now it is about a half turn on the die after contact of the case. You can barely see where the die touches the case. Currently I'am giving no crimp a try.

Sierra Bullets proved years ago that any crimp on their rifle bullets unbalanced them and they shoot less accurate. Tests with their match bullets showed the differences better. They convinced Lee to put a disclaimer in ads saying Sierra rifle bullets should not be crimped in. Sierra doesn't crimp any bullet in accuracy tests for quality control; even ones cannelured for people wanting to crimp them in cases. Crimping introduces another variable.

Nobody getting the best results in center fire rifle matches crimps in bullets. Some people cannot grasp that fact.

Nobody getting the best results in center fire rifle matches crimps in bullets. Some people cannot grasp that fact.

Last edited:

You can use one to fix rounds that fail to gauge or go into battery or you can just put it on the press and pretreat every round. It is kind of a crutch, since so many claim they don't need one, but if use of a combination seat and crimp die has become maddeningly difficult to get just right, the FCD will save the day.

The FCD is not recommended for lead bullets because it anticipates and forces bullets to be jacketed diameters. Lee does little to accommodate loading of cast bullets. For that I use RCBS and Lyman Dies plus a couple specialties from Redding. I keep a separate setup for jacketed/plated, most of which I do on a Lee turret with some Lee dies.

The FCD is not recommended for lead bullets because it anticipates and forces bullets to be jacketed diameters. Lee does little to accommodate loading of cast bullets. For that I use RCBS and Lyman Dies plus a couple specialties from Redding. I keep a separate setup for jacketed/plated, most of which I do on a Lee turret with some Lee dies.

StrutStopper

New member

I only reload a few handgun calibers. I use the Lee FCD. I only crimp lightly. I generally use range brass of mixed head stamps. I find that some rounds move in and out of the FCD easily, but some are definitely sized down by the sizing ring. Would I have a problem chambering those rounds if I didn't use the FCD? I don't know for sure, but since I purchased the 4 die carbide sets, I'll continue to use them. One caveat, to date I've only reloaded straight walled cases with plated bullets. I've read mixed reviews about using the FCD with cast bullets. I'd like to hear about people's FCD experiences with lead bullets as I may place an order with Missouri Bullet Company.

Is there any need to get a factory crimp die?

Not usually. There is nothing magic about a LFCD. The only thing that makes it different from your garden variety seat/crimp die is that it has a collar at its mouth that is of tight tolerance. So if your brass has bulged a little, it'll restore the outside dimension to "factory" (just using their term) spec. This could make the difference between the round chambering in your firearm or not.

Most of the time, as you move the round up into the die, there is no impingement with the collar - The FCD did nothing different than a regular die, in this case. As you complete the ram stroke, it finishes with a (taper in this case) crimp - just like any other die. Sometimes, you'll feel the collar engage the case - and those, the FCD does its "magic" and returns it to "factory" spec. Would this round have failed to feed? Probably would have fed just fine - or not, who knows. But the FCD may have given you some peace of mind.

Bart B said:

Both cases (9mm & 40) headspace on the case mouth so the FCD could cause problems.

I don't know how the FCD changes anything from a crimping standpoint. It performs a taper crimp - just like any other die - and your cases will headspace on the case mouth - just like any other die.

In my experience, if you learn to properly adjust your dies, and don't use bullets way over size (.005"+) then there is no need for a Lee FCD, handgun version. How many bizillion 45 ACPs were successfully reloaded prior to Lee's introduction of their post seating re-sizing die (and that's not counting .32 ACP, .38 Super, and 9mm or any other semi-auto round)? I believe if one has chambering problems with handgun ammo, then one should find out why/what's causing the problem and fix it, not cover up the mistake by resizing as a last step...

Jes my dos centavos from a bit of experience (I have been reloading revolver ammo for 30 years, and semi-auto ammo for 17. The FCD I tried now resided in a landfill somewhere in Southern Oregon).

Jes my dos centavos from a bit of experience (I have been reloading revolver ammo for 30 years, and semi-auto ammo for 17. The FCD I tried now resided in a landfill somewhere in Southern Oregon).

A pause for the COZ

New member

Sure there is an advantage. I use the collet type for almost all my Cast bullet rifle loads and Semi Auto loads.

I also use them in my pistol bullet loads. With one caveat.

I remove the carbide post sizing ring from them. I find that the ring sizes cast bullets smaller than the size I intended to shoot them at.

That defeats the whole purpose of going through all the trouble to slug my bore and ream out sizing dies. Only to have your crimp die squish them back.

Are they necessary?? Of course not. People have reloaded for years and years with out them. I like them though because it allows me to be lazy with my case trimming. As long as they are under the max OAL. We are good.

To crimp with your seating die case OAL is an issue.To be honest, I would rather shoot than spend the time trimming brass when i dont have too.

To pop out the carbide ring is not overly hard.

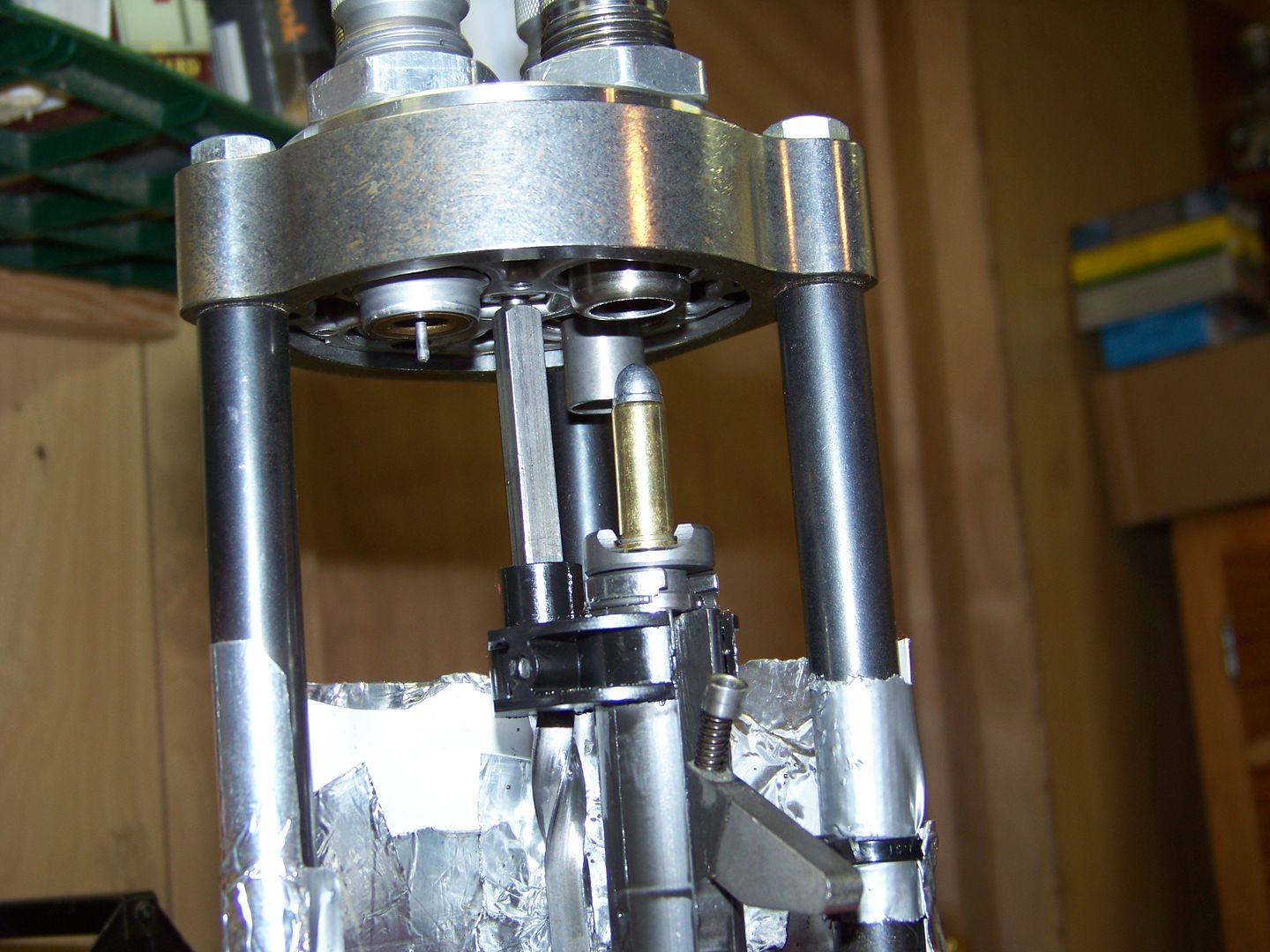

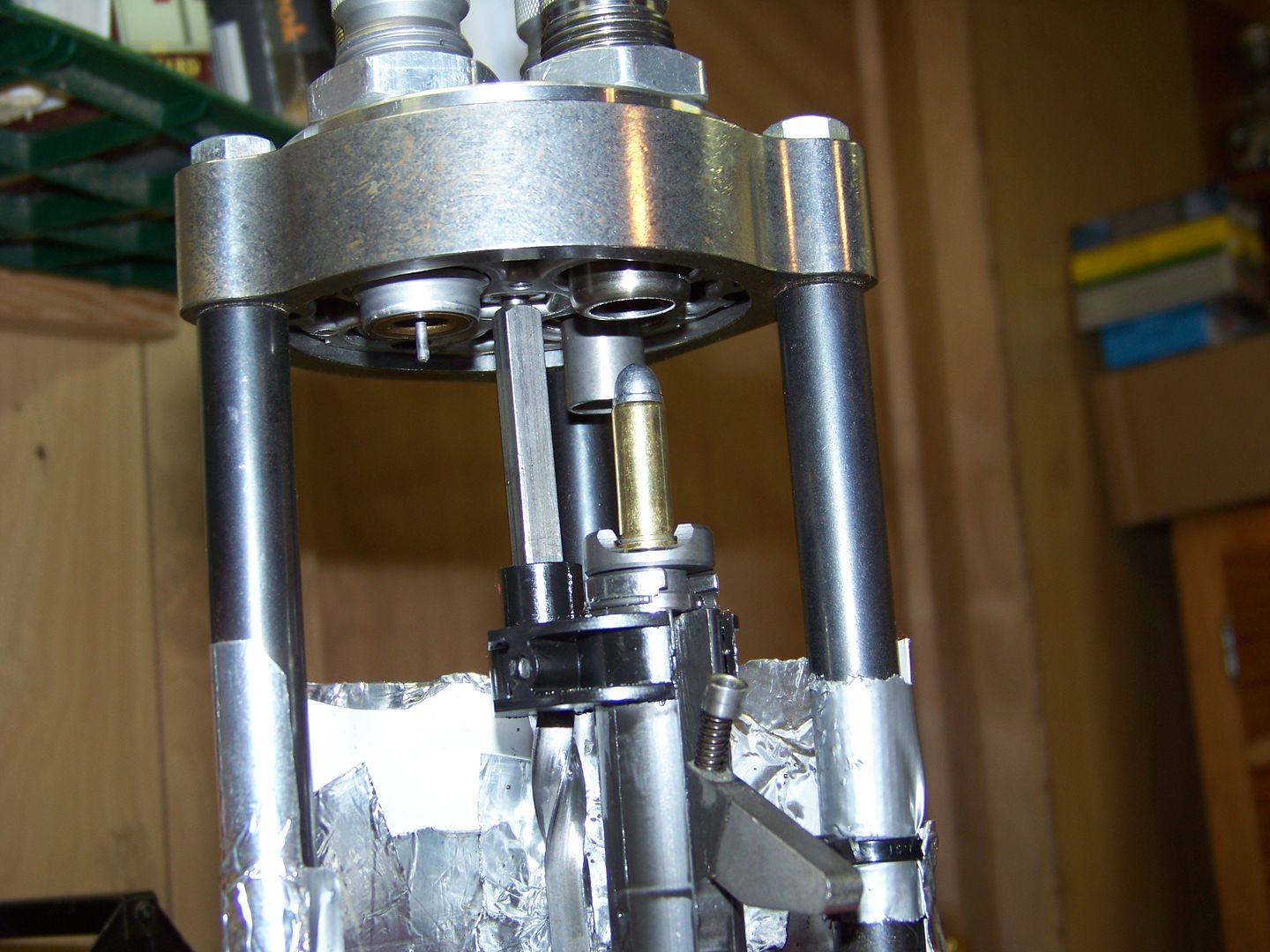

Here are some images.

Tap out the press fit ring. Use what ever fits.

Works good. On some though you may have to take a dremel and put a slight bevel on the crimper if the rounds catch on it going in.

I also use them in my pistol bullet loads. With one caveat.

I remove the carbide post sizing ring from them. I find that the ring sizes cast bullets smaller than the size I intended to shoot them at.

That defeats the whole purpose of going through all the trouble to slug my bore and ream out sizing dies. Only to have your crimp die squish them back.

Are they necessary?? Of course not. People have reloaded for years and years with out them. I like them though because it allows me to be lazy with my case trimming. As long as they are under the max OAL. We are good.

To crimp with your seating die case OAL is an issue.To be honest, I would rather shoot than spend the time trimming brass when i dont have too.

To pop out the carbide ring is not overly hard.

Here are some images.

Tap out the press fit ring. Use what ever fits.

Works good. On some though you may have to take a dremel and put a slight bevel on the crimper if the rounds catch on it going in.

I note already posting on the rifle crimp dies. They are completely different. They are a collet type die that crimps a rifle case in a ring around the bottom edge of the case mouth like the ones Lake City puts in ball ammo rounds. And yes, they do distort their bullets, but the accuracy requirement for ball ammo is very low by target shooting standards, and bullets staying in place in full auto feed is their primary concern.

The rifle die is called a: Lee Factory crimp Die.

The pistol die is called a: Lee Carbide Factory Crimp Die.

The pistol die, as described, has a carbide cartridge OD sizing ring and an internal ring with the profile of a fairly conventional crimp shoulder. No collets are involved.

If you are reloading 40 S&W, the Lee Carbide Factory Crimp Die plus the Lee accessory Bulge Buster tool may be useful. 40 S&W is famous for developing a bulge in a partially unsupported barrel that is not fully ironed out by a conventional sizing die, so the rounds don't feed well. If you have this situation, the Lee die is put in your press and the crimp ring and its retaining plug are removed and the Bulge Buster accessory forces your cases completely through the OD sizing ring, head and all, to remove the bulge before you start the reloading process. This insures feeding.

If you then also use the Lee CFCD to form your crimp, that's a bonus. You don't have to have a separate crimp die, but most match shooters have reported for years that separately crimped pistol ammunition is a little more accurate. I'm not sure why, but suspect it is mainly about eliminating the very slight shaving of the bullet that can occur when seating and crimping simultaneously. The main thing, as Bart warned, is you have to be sure not to crimp below the minimum SAAMI mouth OD for the case unless you are headspacing on the bullet before the case mouth reaches the end of the chamber.

The rifle die is called a: Lee Factory crimp Die.

The pistol die is called a: Lee Carbide Factory Crimp Die.

The pistol die, as described, has a carbide cartridge OD sizing ring and an internal ring with the profile of a fairly conventional crimp shoulder. No collets are involved.

If you are reloading 40 S&W, the Lee Carbide Factory Crimp Die plus the Lee accessory Bulge Buster tool may be useful. 40 S&W is famous for developing a bulge in a partially unsupported barrel that is not fully ironed out by a conventional sizing die, so the rounds don't feed well. If you have this situation, the Lee die is put in your press and the crimp ring and its retaining plug are removed and the Bulge Buster accessory forces your cases completely through the OD sizing ring, head and all, to remove the bulge before you start the reloading process. This insures feeding.

If you then also use the Lee CFCD to form your crimp, that's a bonus. You don't have to have a separate crimp die, but most match shooters have reported for years that separately crimped pistol ammunition is a little more accurate. I'm not sure why, but suspect it is mainly about eliminating the very slight shaving of the bullet that can occur when seating and crimping simultaneously. The main thing, as Bart warned, is you have to be sure not to crimp below the minimum SAAMI mouth OD for the case unless you are headspacing on the bullet before the case mouth reaches the end of the chamber.

A pause for the COZ,

Just looking at your pics.... a torch on the die and then a hammer on the die, has my imagination running open loop. I give up. Reading text.

You are removing the carbide ring?

That's the best part

I grind them down with diamond to get closer to the case web. Then the carbide cracks with use. Repeat.

Cast bullets... I guess you know what you are doing.

Just looking at your pics.... a torch on the die and then a hammer on the die, has my imagination running open loop. I give up. Reading text.

You are removing the carbide ring?

That's the best part

I grind them down with diamond to get closer to the case web. Then the carbide cracks with use. Repeat.

Cast bullets... I guess you know what you are doing.

I could NOT get my 45ACP's to plop or cycle at all.

The FCD and using 451 boolits solved the problems and now I can shoot pretty much any of the several 45 weights I cast for my 1911's.

With so much success, I bought one for my 9mm and 40 S&W semi's. I had been having cycle load problems (off and on) a lot with those at times and the FDC solved ALL the problems.

And......yes..... I did (and know how to) adjust the standard dies until I was blue in the face! They did not work for me. The FCD did!

I love the FCD. Some hate it. To each his own. Buy one....they are very inexpensive.....and try it. It is very re-sellable.

NOTE: I PC everything. No PC comes off and there is no swaging of the boolit as some claim. "You just gotta hold yer mouth right!"

banger

The FCD and using 451 boolits solved the problems and now I can shoot pretty much any of the several 45 weights I cast for my 1911's.

With so much success, I bought one for my 9mm and 40 S&W semi's. I had been having cycle load problems (off and on) a lot with those at times and the FDC solved ALL the problems.

And......yes..... I did (and know how to) adjust the standard dies until I was blue in the face! They did not work for me. The FCD did!

I love the FCD. Some hate it. To each his own. Buy one....they are very inexpensive.....and try it. It is very re-sellable.

NOTE: I PC everything. No PC comes off and there is no swaging of the boolit as some claim. "You just gotta hold yer mouth right!"

banger

Last edited:

chris in va

New member

It's an absolute must for my 9mm. Every now and then I get a lead bullet that doesn't seat straight and makes a bulged spot in the case.

It's just good insurance. I'd much rather have a gun that fires reliably than one with slightly better accuracy but jams.

It's just good insurance. I'd much rather have a gun that fires reliably than one with slightly better accuracy but jams.

From what I've read on forums, I was starting to believe that the 3rd die in a pistol set was just to fill and balance the box for shipping, and you were supposed to throw it away when you opened it.

If you can't get the job done with the die that came in your set, you probably either have some unusual or nonstandard circumstances or else you are probably not setting up and using them correctly, and the alternatives are les critical of proper setup.

If you can't get the job done with the die that came in your set, you probably either have some unusual or nonstandard circumstances or else you are probably not setting up and using them correctly, and the alternatives are les critical of proper setup.