Master Blaster

New member

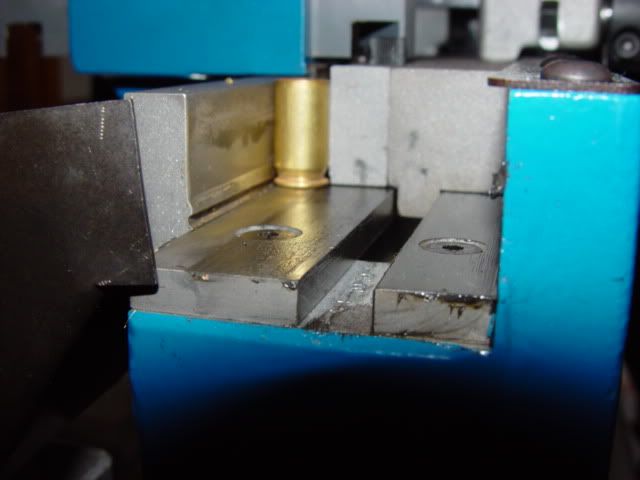

I had my .45 acp Hornady sizing die wear out in my LNL AP around 25,000 rounds, it started to fail to properly size Remington brass (thinner than other brands) first and the sized brass would not hold plated bullets with proper neck tension to prevent set backs. It took me a while to figure it out but a new sizing die fixed the issue.