Test ladders (from the fact POI tends to climb as charge weight is increased) are a good way to identify load sweet spots, but it is also good to be aware there is more than one influence and effect to watch out for.

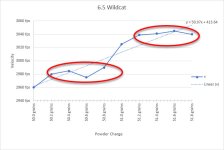

The velocity nodes were noticed long ago by Creighton Audette (the term Audette Ladder comes from his advocating their use in the 1980's) and Randolf Constantine and others. However, not all velocity nodes necessarily produce the best accuracy, even if they do tend to produce "better" accuracy than being off such a node. Dave Milosovich, writing in the Precision Shooting Reloading Guide (1995) offers an example on pages 90-91, firing 20 rounds in 0.2-grain increments that seem to exhibit stalling velocity increase with charge in two places occurring about 1.6 grains apart (follow the "Brief Overview…" link in this article). That's not very far apart. The 6.5 Guys advocate for a 10 shot load workup method based on the same increments showed two such spots within just 10 shots (about half as far apart). Here's a graph I made based on the data in their video at that link.

I've had individual sweet spots wider than the distances between these velocity nodes before, so something seems at least incomplete if not actually amiss. Here's what I think it is:

Checking in QuickLOAD it becomes apparent the velocity node spacing tracks the barrel time differences predicted by Chris Long's pressure waves in his Optimum Barrel Time theory. This theory is about the barrel distortion effects of pressure wave traveling at the speed of sound longitudinally in the steel. These waves were first spotted by Dr. Lloyd Brownell and are reported on pages 19-24 (30-35, as Acrobat counts them) of his 1965 study of absolute pressure in a Springfield '03 rifle. If a wave happens to be constricting steel near the throat when the gun's peak pressure is reached, it can raise the peak pressure and velocity a small amount. As charge weight is increased beyond that point the wave simultaneously has its phase relationship to the throat changing and widening, this can rob the cartridge of the expected increase in velocity over the next several increments of charge increase. Conversely, it will cause pressure to rise more than expected when the wave is changing phase on the other side of its peak.

So, a velocity flat spot can be found and had and that's all useful as it stabilizes the performance of the load velocity. But that's not the only thing going on in the system. At the same time, the barrel is bending an moving the muzzle. Below is an image of a ladder test group fired at 325 yards from a .270 Winchester sporter using the 140 grain Hornady SST bullet. It's one I helped a fellow identify the sweet spot for about a dozen years ago. I have put a spline fit into the plot so you can see there are apparent velocity nodes as he steps up through the load. This ladder was shot with 0.3-grain steps, to the 17 steps span 5.1 grains of powder, more than either Milosovich or the 6.5 Guys tried. Shots 3,4, and 5 don't look like much of a flat spot, but at 0.3 grains per step, it's almost a four-shot flat in the 0.2-grain steps the aforementioned experimenters used. By their reckoning, it's a great accuracy node. Looking at shots 11 through 16 you get a confusing group-like cluster, with #14 high. That is why there are several spline curves I tried out, eliminating shots as potential outliers to see what happened. However, even shot 14 is part of an average that is fairly flat.

To sort that out, I went to a polynomial curve fit to average out small velocity nodes and identify the biggest flat spot, which is the one due to muzzle deflection. I did that with the brown line in the plot below. I suggested he try all the apparent small flat spots, but none did great. The big flat spot between 13 and 14, though yielded very good results. When he tried that node at 100 yards (he couldn't get to the long range that day) he got two 3-shot groups of 0.3 inches that did not open at all when the two targets were overlapped. A 0.3-inch six-shot group, in other words. That's not a big shot count, but given the size, it limits how big a worst-case group could randomly be to within 0.42" or better 95% of the time. Not bad for a .270 sporter.

The reason I know the barrel deflection is responsible for one aspect of the flat spot is that barrel tuners work. They do nothing to velocity node locations that I've ever observed. But they can tune a barrel so its muzzle deflection matches a velocity node and that gives maximum accuracy quite nicely.

I suspect the reason seating depth changes can tune groups even smaller is it changes the phase relationship between the pressure wave and the barrel deflection by altering when the pressure wave initiates (when the bullet smacks into the throat). This allows you to tune to have both a barrel bend node and a velocity node that are synchronized, just as a barrel tuner may do. However, I'll warn you I have not proved this. I have a barrel tuner on one gun and I want to find if, once tuned optimally, I can make groups still smaller with seating depth tuning or not. If I can, my suspicion is wrong. If I can only make it worse, that is good evidence that my guess about tuning the phase relationship is right. With any luck, I'll have more on that later in the year.

Some guns may have issues arriving at the above nirvana by having problems with barrel contact with the stock or uneven loading of hangers under recoil and the like. So they don't all tune out neat and clean. Indeed, the complexity of the above relationships likely signals you pretty well that the system can be derailed by ill-tuning factors; especially those affecting consistency from one shot to the next.

One thing that has bothered me about all the single-string ladders is that you are often looking for variations a lot smaller than the standard deviation around the expected straight line fit is. I would fire several of them to check for a velocity node being real.

Finally, what distance can you shoot a successful ladder or round robin with? In my experience, this depends on how whippy the barrel is. If you have a free-floating ultra-light barrel of appreciable length, 100 yards can show you quite a bit of muzzle deflection. If you are shooting a benchrest gun like Audette was, it's may be difficult to make the effect out until you get to 300 yards, though Audette thought he could make it out at 200 yards, Randolf Constantine felt 200 was necessary. Cylinder rigidity increases as the fourth power of the diameter, so it doesn't take much extra barrel thickness to wind up with a lot less deflection. 100 yards won't show you loading errors that produce too high a velocity SD, but muzzle bending should be discernable with many sporters. Bottom line, as always: try it with your gun to see what you can tell from the test at shorter and longer ranges.

The velocity nodes were noticed long ago by Creighton Audette (the term Audette Ladder comes from his advocating their use in the 1980's) and Randolf Constantine and others. However, not all velocity nodes necessarily produce the best accuracy, even if they do tend to produce "better" accuracy than being off such a node. Dave Milosovich, writing in the Precision Shooting Reloading Guide (1995) offers an example on pages 90-91, firing 20 rounds in 0.2-grain increments that seem to exhibit stalling velocity increase with charge in two places occurring about 1.6 grains apart (follow the "Brief Overview…" link in this article). That's not very far apart. The 6.5 Guys advocate for a 10 shot load workup method based on the same increments showed two such spots within just 10 shots (about half as far apart). Here's a graph I made based on the data in their video at that link.

I've had individual sweet spots wider than the distances between these velocity nodes before, so something seems at least incomplete if not actually amiss. Here's what I think it is:

Checking in QuickLOAD it becomes apparent the velocity node spacing tracks the barrel time differences predicted by Chris Long's pressure waves in his Optimum Barrel Time theory. This theory is about the barrel distortion effects of pressure wave traveling at the speed of sound longitudinally in the steel. These waves were first spotted by Dr. Lloyd Brownell and are reported on pages 19-24 (30-35, as Acrobat counts them) of his 1965 study of absolute pressure in a Springfield '03 rifle. If a wave happens to be constricting steel near the throat when the gun's peak pressure is reached, it can raise the peak pressure and velocity a small amount. As charge weight is increased beyond that point the wave simultaneously has its phase relationship to the throat changing and widening, this can rob the cartridge of the expected increase in velocity over the next several increments of charge increase. Conversely, it will cause pressure to rise more than expected when the wave is changing phase on the other side of its peak.

So, a velocity flat spot can be found and had and that's all useful as it stabilizes the performance of the load velocity. But that's not the only thing going on in the system. At the same time, the barrel is bending an moving the muzzle. Below is an image of a ladder test group fired at 325 yards from a .270 Winchester sporter using the 140 grain Hornady SST bullet. It's one I helped a fellow identify the sweet spot for about a dozen years ago. I have put a spline fit into the plot so you can see there are apparent velocity nodes as he steps up through the load. This ladder was shot with 0.3-grain steps, to the 17 steps span 5.1 grains of powder, more than either Milosovich or the 6.5 Guys tried. Shots 3,4, and 5 don't look like much of a flat spot, but at 0.3 grains per step, it's almost a four-shot flat in the 0.2-grain steps the aforementioned experimenters used. By their reckoning, it's a great accuracy node. Looking at shots 11 through 16 you get a confusing group-like cluster, with #14 high. That is why there are several spline curves I tried out, eliminating shots as potential outliers to see what happened. However, even shot 14 is part of an average that is fairly flat.

To sort that out, I went to a polynomial curve fit to average out small velocity nodes and identify the biggest flat spot, which is the one due to muzzle deflection. I did that with the brown line in the plot below. I suggested he try all the apparent small flat spots, but none did great. The big flat spot between 13 and 14, though yielded very good results. When he tried that node at 100 yards (he couldn't get to the long range that day) he got two 3-shot groups of 0.3 inches that did not open at all when the two targets were overlapped. A 0.3-inch six-shot group, in other words. That's not a big shot count, but given the size, it limits how big a worst-case group could randomly be to within 0.42" or better 95% of the time. Not bad for a .270 sporter.

The reason I know the barrel deflection is responsible for one aspect of the flat spot is that barrel tuners work. They do nothing to velocity node locations that I've ever observed. But they can tune a barrel so its muzzle deflection matches a velocity node and that gives maximum accuracy quite nicely.

I suspect the reason seating depth changes can tune groups even smaller is it changes the phase relationship between the pressure wave and the barrel deflection by altering when the pressure wave initiates (when the bullet smacks into the throat). This allows you to tune to have both a barrel bend node and a velocity node that are synchronized, just as a barrel tuner may do. However, I'll warn you I have not proved this. I have a barrel tuner on one gun and I want to find if, once tuned optimally, I can make groups still smaller with seating depth tuning or not. If I can, my suspicion is wrong. If I can only make it worse, that is good evidence that my guess about tuning the phase relationship is right. With any luck, I'll have more on that later in the year.

Some guns may have issues arriving at the above nirvana by having problems with barrel contact with the stock or uneven loading of hangers under recoil and the like. So they don't all tune out neat and clean. Indeed, the complexity of the above relationships likely signals you pretty well that the system can be derailed by ill-tuning factors; especially those affecting consistency from one shot to the next.

One thing that has bothered me about all the single-string ladders is that you are often looking for variations a lot smaller than the standard deviation around the expected straight line fit is. I would fire several of them to check for a velocity node being real.

Finally, what distance can you shoot a successful ladder or round robin with? In my experience, this depends on how whippy the barrel is. If you have a free-floating ultra-light barrel of appreciable length, 100 yards can show you quite a bit of muzzle deflection. If you are shooting a benchrest gun like Audette was, it's may be difficult to make the effect out until you get to 300 yards, though Audette thought he could make it out at 200 yards, Randolf Constantine felt 200 was necessary. Cylinder rigidity increases as the fourth power of the diameter, so it doesn't take much extra barrel thickness to wind up with a lot less deflection. 100 yards won't show you loading errors that produce too high a velocity SD, but muzzle bending should be discernable with many sporters. Bottom line, as always: try it with your gun to see what you can tell from the test at shorter and longer ranges.