Absolutely false!

Call any ammo manufacturer or gun manufacturer and they will tell you the two are interchangeable. .308 Winchester does come in more varieties than 7.62mm NATO because the military does not need so many varieties but that does not make it unsafe to shoot in a serviceable weapon.

Call Winchester, they engineered the round. 7.62mm is nothing more than the military version of the .308 Winchester specifications.

Internet experts have been generating myths about this for a long time. If you are buying your ammo off the shelf from a reputable ammunition manufacturer, .308 Winchester and 7.62mm NATO are interchangeable. If you have a serviceable rifle that is within its manufacturing specifications, it is safe to shoot either cartridge.

All modern .308 rifles can chamber and shoot modern .308 and 7.62 NATO ammunition without any problems, such as the SAINT Victor .308 rifles. The 7.62 NATO M1A can also safely fire both rounds.

If you plan on using a surplus rifle chambered in either .308 Win or 7.62 NATO, you should have the gun’s headspace checked by a professional to ensure you can safely shoot .308 ammunition. You can also check this on your own with quality Go-NoGo headspace gauges.

https://www.thearmorylife.com/7-62-nato-vs-308-is-there-a-difference/

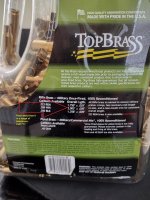

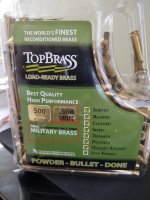

If you are a reloader then there are some differences due to the thicker military casings and the way military chambers are formed. I am sure that anyone being an experimental weapon engineer with their bubba handloads might be able to damage their gun and injure themselves but then they it does not matter what caliber or weapon they chose as the results of their experimentation will be the same.

It is safe to shoot 308 Winchester in your 7.62x51 rifles (even the Ishapores) and vice versa. Handloaders should be aware that they should reduce the amount of powder when using military 7.62 NATO cases by about 10-

12% and work up to safe pressures with corresponding velocities.

https://thefiringline.com/forums/attachment.php?attachmentid=107863&d=1532181807

Last edited: