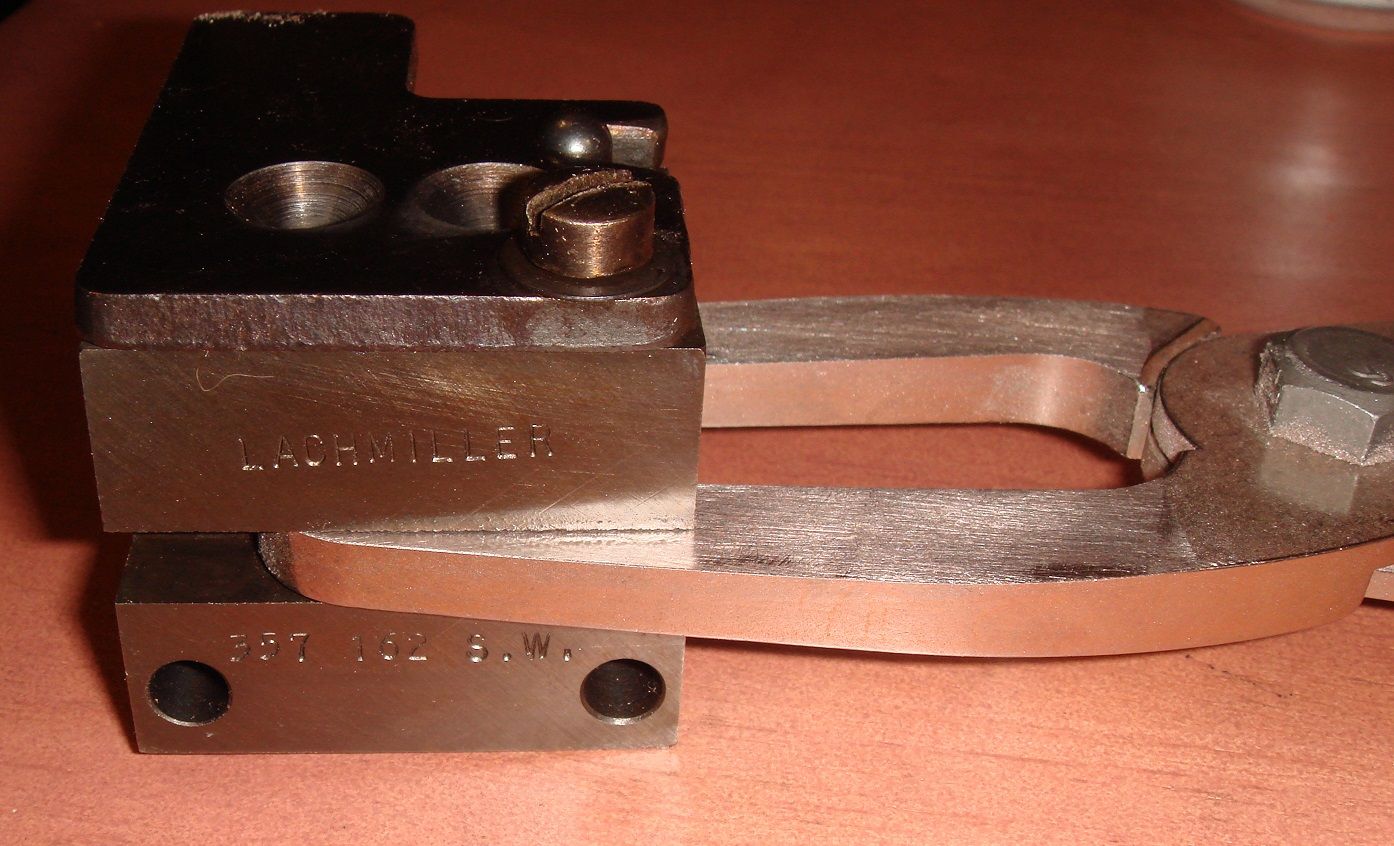

You know the reasoning...I got this mould so I just have to get a gun to go with it..right ...that is logical thinking???

Definitely! That's why I got two .44 molds, and both Lee and Lyman sizing dies, even though I got no .44 - now I have a reason to buy one!