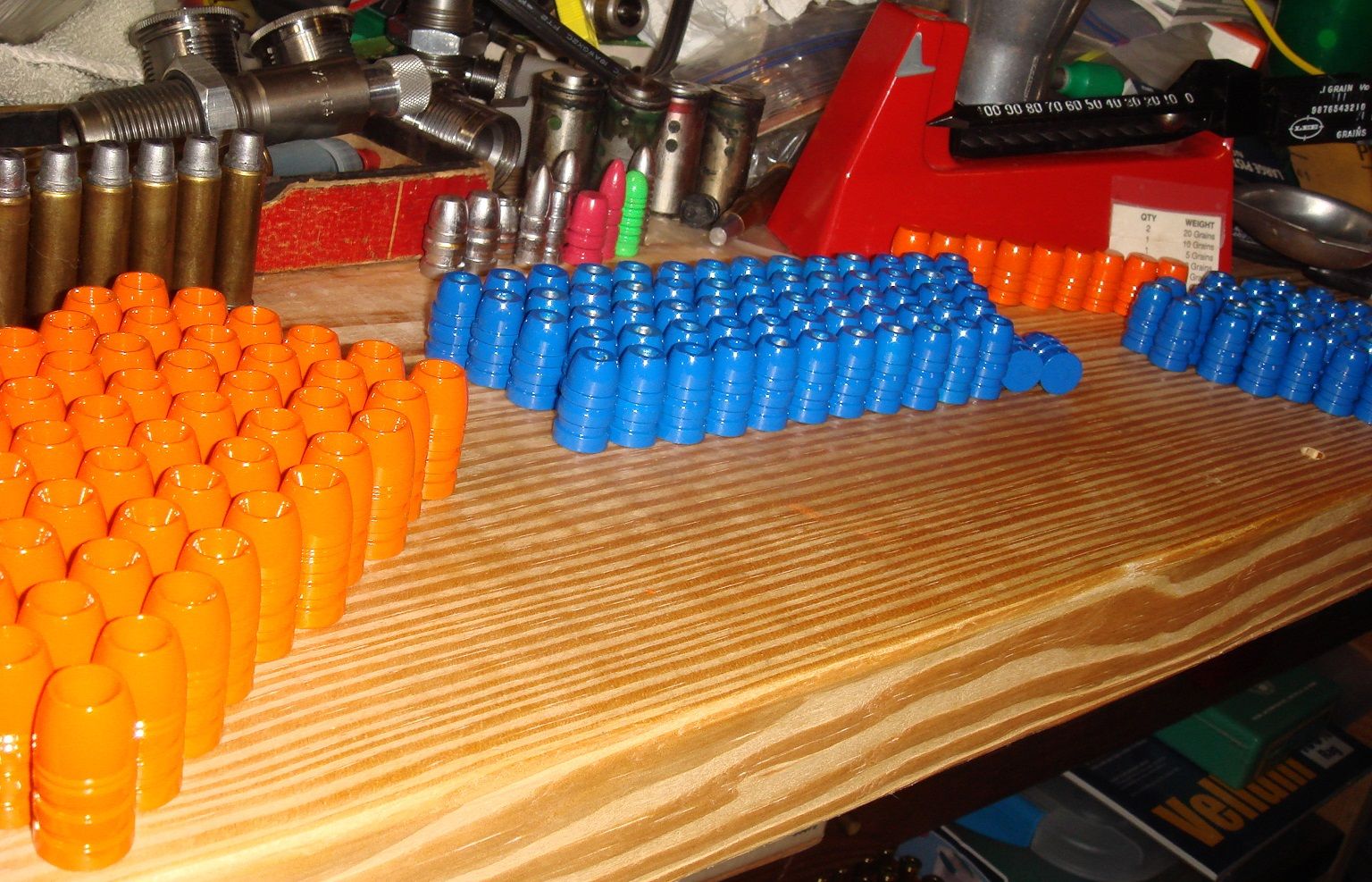

Can't sleep, so here's the first few .480 Rugers through the sizer. I got a big pile of em to go. I made up about 60# of alloy today for my HP making, so I'm going to be as happy as a clam, casting and lubing for these few precious days off work!!!

I hope everyone has a great Thanksgiving!

I hope everyone has a great Thanksgiving!