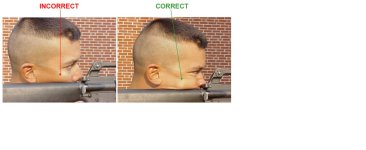

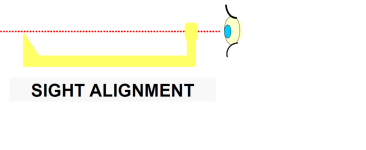

Gunplummer said:Most folks can't shoot worth a damn, I have been to the range often enough to see it. Probably a spot weld problem?

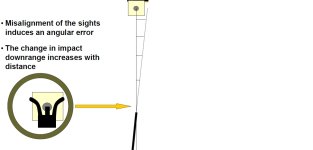

Probably more of a .300 Winchester Magnum is my first gun problem. Cheek position is just one link in the chain.

Also, a lot of people think that hitting a pie plate at 100 yards is "good shooting".