You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think I'll build a rotary tumbler...

- Thread starter nemesiss45

- Start date

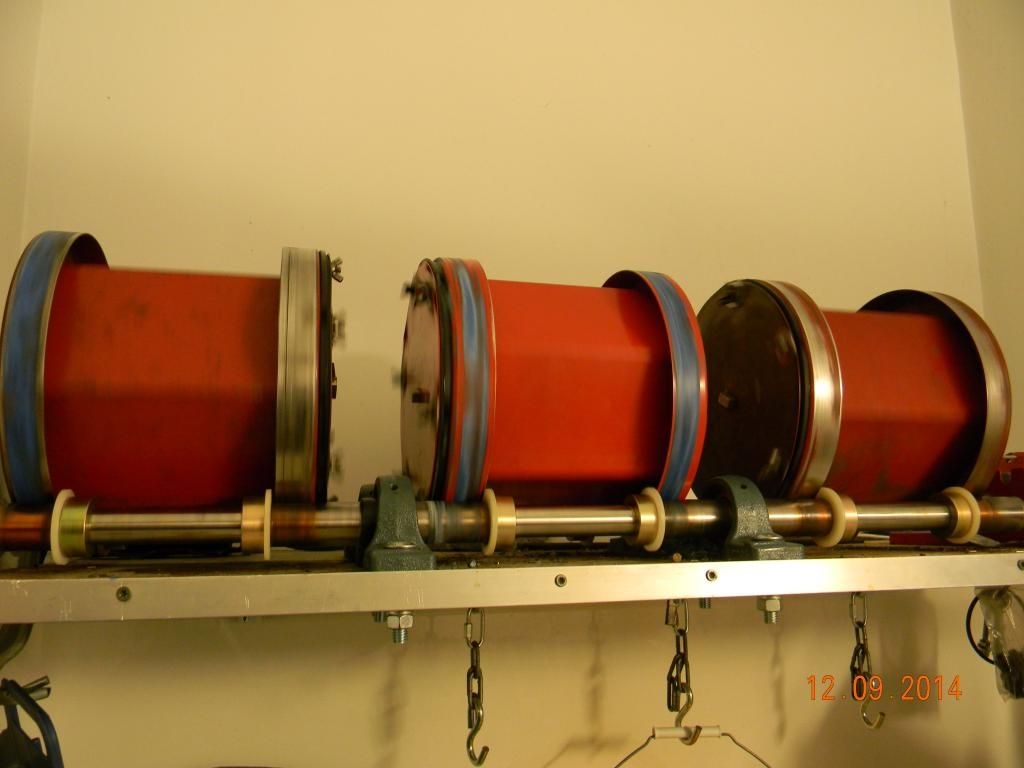

This is a 12.7 gallon one I built. When not in use stuck in a corner it takes up as much space as the bucket itself would and will do 2000 45 acp cases per batch easy.

http://thefiringline.com/forums/showthread.php?t=470484&highlight=tumbler

http://thefiringline.com/forums/showthread.php?t=470484&highlight=tumbler

nemesiss45

New member

Here's an update, I gutted the saw down to the base structure and deck. I mounted the moto. The cord plugs in where the saw motor did, so i use the switch to start it. I used some angled fixed caster bases to mount the garage door wheels. The pulley off my old tumber will be used on the drive shaft of the new one. I used a length of rubber hose to wrap the shaft to give it traction and a bigger diameter. I am just waiting on a pair of pillow block bearings to mount it and i need to order the pulley for the motor and a drive belt.

I stripped down the cooler, cut off the spigot, and filled the bung hole with caulk (no pun intended). I have not decided on what to do for agitators yet.

I stripped down the cooler, cut off the spigot, and filled the bung hole with caulk (no pun intended). I have not decided on what to do for agitators yet.

great idea using the door rollers with that ribbed jug. they ought to keep your drum from wandering very nicely.

However, (there's always a however) the bearings and steel quality used in making those garage door track wheels is pretty soft. the race is of the same soft metal as the wheel. Those wheels will likely turn as many times in a single 2 or 3 hour batch as a garage door would turn them in a couple years.

just a potential weak point to keep an eye on. I'd flush and rinse them real good, and then repack with a high quality grease.

However, (there's always a however) the bearings and steel quality used in making those garage door track wheels is pretty soft. the race is of the same soft metal as the wheel. Those wheels will likely turn as many times in a single 2 or 3 hour batch as a garage door would turn them in a couple years.

just a potential weak point to keep an eye on. I'd flush and rinse them real good, and then repack with a high quality grease.

nemesiss45

New member

Yeah, I was thinking the same thing. I really just used them because they cost me about 25 cents and saved me from buying 2 shafts and 2 sets of bearing. I figured I could run them for now and see how they last. If they wear out, but i like how they hold the jug, i can get a pair of polyurethane fixed casters with sealed bearings and sharpen their profile to track like them... but if the jug doesnt like running on wheels, I will get a second shaft.

nemesiss45

New member

Got my pillow block bearings this morning, so before work I mounted them and did a little test run. the drive band is running on the motor shaft because my pulley and belt have not arrived, so it should run a bit faster when complete. Here is a little video: https://youtu.be/PU9h0ILkGBU

here's the post with the formula

http://thefiringline.com/forums/showthread.php?t=514454&highlight=rpm

http://thefiringline.com/forums/showthread.php?t=514454&highlight=rpm

nemesiss45

New member

I got my v-belt today, so I decided to take er for a test drive.

I ran into one minor issue, the cooler I am using does not really seal on top.. I guess it makes sense so the spigot would work well ... but I will need to lay a bead of silicone or something to keep it from dripping. I was able to tighten it enough that it kept most of the water in for a 3 hour tumble.

That said... I'm am so happy to have a bigger tumbler... I just ran about 450 30-06 which was maybe half capacity. I do need more pins... I got the outsides clean, but the primer pockets left a little to be desired... more pins will get up inside better. These were some of the dirtiest cases I have ever tumbled, and while the are not showroom shiny, they are pretty darn clean considering how they started.

I ran into one minor issue, the cooler I am using does not really seal on top.. I guess it makes sense so the spigot would work well ... but I will need to lay a bead of silicone or something to keep it from dripping. I was able to tighten it enough that it kept most of the water in for a 3 hour tumble.

That said... I'm am so happy to have a bigger tumbler... I just ran about 450 30-06 which was maybe half capacity. I do need more pins... I got the outsides clean, but the primer pockets left a little to be desired... more pins will get up inside better. These were some of the dirtiest cases I have ever tumbled, and while the are not showroom shiny, they are pretty darn clean considering how they started.

looking good.

finding a way to make a good lid gasket could be a challenge. waiting to hear how you ultimately solve that. Before I settled on my pvc pipe drum, I too thought about trying to make a gasket with some type of silicone caulking but kept getting myself wrapped around the axle. especially knowing once that silicone was cured in place there would be no way to remove it to try something else. perhaps an experiment with some other (throw away) screw on capped jug?

a side note. I do get a tiny bit of pressure build up inside the drum. whether that is from the soap suds or from the heat off my motor which is sitting under the drum, I don't know.

what drum speed did you end up with and do you have any vanes in the drum? If you do not have vanes in there yet I suspect you will see better results with vanes. My drum is 3.7 gallons and I generally use about 10 pounds of pins. although I will go higher if I am running a larger batch.

finding a way to make a good lid gasket could be a challenge. waiting to hear how you ultimately solve that. Before I settled on my pvc pipe drum, I too thought about trying to make a gasket with some type of silicone caulking but kept getting myself wrapped around the axle. especially knowing once that silicone was cured in place there would be no way to remove it to try something else. perhaps an experiment with some other (throw away) screw on capped jug?

a side note. I do get a tiny bit of pressure build up inside the drum. whether that is from the soap suds or from the heat off my motor which is sitting under the drum, I don't know.

what drum speed did you end up with and do you have any vanes in the drum? If you do not have vanes in there yet I suspect you will see better results with vanes. My drum is 3.7 gallons and I generally use about 10 pounds of pins. although I will go higher if I am running a larger batch.

nemesiss45

New member

well, the silicone caulk failed. it just made the seal worse. I think I put it on too thick, the lid would not screw on very tight at all. I was able to pull the silicone off though, and am back to square 1. I may see if I can find some rubber tape or weather stripping... but I may just have to go with pipe.

I have not put any vanes in yet. I am considering picking up 2 appropriately sized hdpe cutting boards and trimming them, forming a cross, then making cutouts for the material to pass through the structure should support itself and allow me to not secure it to the walls of the drum. then I can pull it out when the batch it done so it will not be in my way emptying the container.

as for the speed. my rough 1 Mississippi method it about 60 rpm, but I just counted for like 3 seconds, so I could be off by a fair amount.

I have not put any vanes in yet. I am considering picking up 2 appropriately sized hdpe cutting boards and trimming them, forming a cross, then making cutouts for the material to pass through the structure should support itself and allow me to not secure it to the walls of the drum. then I can pull it out when the batch it done so it will not be in my way emptying the container.

as for the speed. my rough 1 Mississippi method it about 60 rpm, but I just counted for like 3 seconds, so I could be off by a fair amount.

nemesiss45

New member

yeah, I've got a lyman vibratory tumbler, and I've got a smaller rotary tumbler as well.

I greatly prefer the rotary tumbler. it cleans the whole case, not just the outside, so I don't have to worry about my primer pockets caking up. and I don't have to worry about getting corn cob stuck in my flash holes. the stainless media pours right out of the cases, so I don't have to sit there sifting and shaking for 15 minutes while I bounce corn cob all over my workspace. the stainless media does not load up with gunk and have to be replaced, it is pretty much a 1 time buy (though as you lose a few pins here and there, you may need to add some more.)

My small rotary tumbler is on its last legs, so I was faced with the prospect of either buying a new one for $200+ that would have the same capacity as my old one or building one which I had 90% of the parts for which could handle significantly more brass. I have, to date, spent $35 on this project and it is functional. it has a few kinks to work out, but I'd say it was a few hours well spent.

I greatly prefer the rotary tumbler. it cleans the whole case, not just the outside, so I don't have to worry about my primer pockets caking up. and I don't have to worry about getting corn cob stuck in my flash holes. the stainless media pours right out of the cases, so I don't have to sit there sifting and shaking for 15 minutes while I bounce corn cob all over my workspace. the stainless media does not load up with gunk and have to be replaced, it is pretty much a 1 time buy (though as you lose a few pins here and there, you may need to add some more.)

My small rotary tumbler is on its last legs, so I was faced with the prospect of either buying a new one for $200+ that would have the same capacity as my old one or building one which I had 90% of the parts for which could handle significantly more brass. I have, to date, spent $35 on this project and it is functional. it has a few kinks to work out, but I'd say it was a few hours well spent.

Just seems like a lot of effort to build a tumbler when ya can buy.........

I have, to date, spent $35 on this project and it

is functional. it has a few kinks to work out, but I'd say it was a few hours well spent.

and of course there is that bit of satisfaction, knowledge, and experience gained. Not unlike reloading in general, or so my thinks....

oldmanFCSA

New member

nemesiss45

New member

Very nice ^

Emerson Biggies

New member

Cheapo parts for Thumbler's

Call Thumbler's customer service.

They offer used tumblers and parts for same from machines that were used in demo's etc. at prices you will love.

I got a used drum for my 1 pounder for just a few bucks and it was almost new.

Call Thumbler's customer service.

They offer used tumblers and parts for same from machines that were used in demo's etc. at prices you will love.

I got a used drum for my 1 pounder for just a few bucks and it was almost new.

nemesiss45

New member

Thanks for the heads up, I'll try that