Mosin-Marauder

New member

Drum Roll Please....

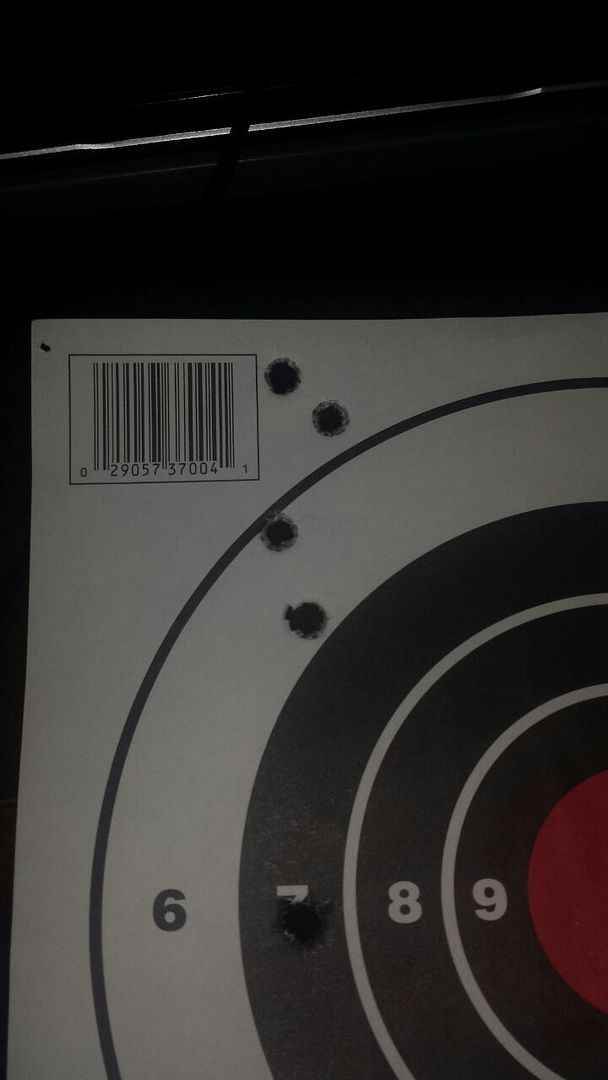

Turns out my rifle hates 4064.

100 Yards

51.2 Grains H4350

180 Grain Speer SPT

WLR Primer

Win Cases

I pulled the one that hit the 7, excluding that, it is 1 7/8" group. I'm very happy, though with a bit more practice (and a change in primers) I hope to eliminate the vertical stringing problem.

Overall very happy, thanks again everyone (and thanks for sharing your load, Josh!)

Regards,

-Mo.

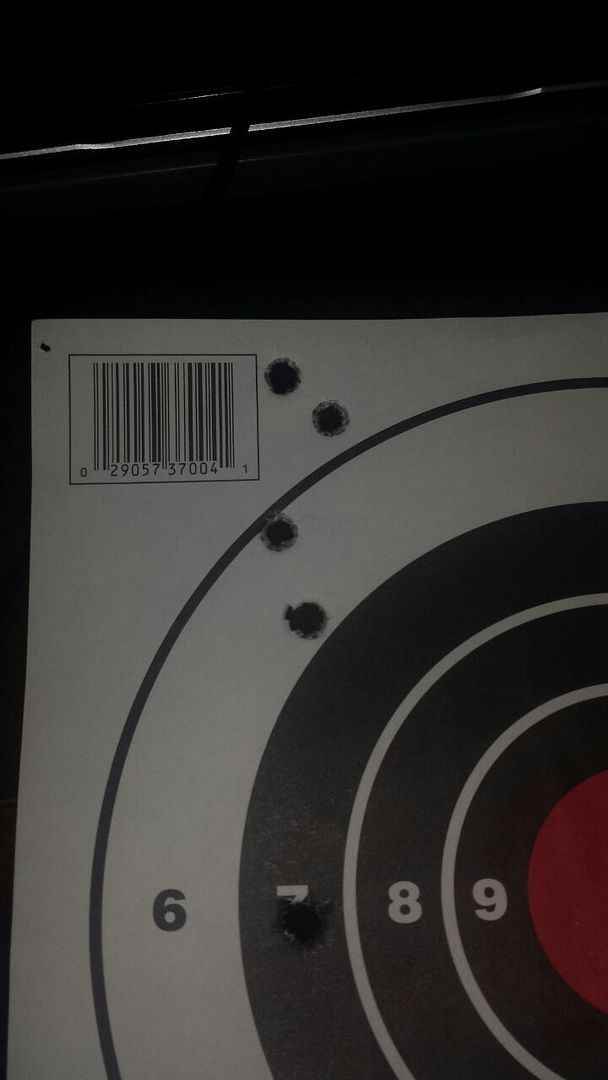

Turns out my rifle hates 4064.

100 Yards

51.2 Grains H4350

180 Grain Speer SPT

WLR Primer

Win Cases

I pulled the one that hit the 7, excluding that, it is 1 7/8" group. I'm very happy, though with a bit more practice (and a change in primers) I hope to eliminate the vertical stringing problem.

Overall very happy, thanks again everyone (and thanks for sharing your load, Josh!)

Regards,

-Mo.