Powder Metering

As has happened before, the question of powder metering always seems to follow on with weight questions, and with good reason. It needs some consideration.

The problem is that you are trying to load cartridges to release the same amount of energy in the same amount of time. This is tricky, because several things affect your actual result.

The idea with weight or volume is that you put the same amount of chemical potential energy into the case each time. Weight has the advantage of being a more consistent measure of potential energy content than volume is, which is why most load data is by weight rather than volume, though it can err up to the equivalent of about 1.5% from load manual values due to variation in moisture content which depends on storage conditions.

Powder does not seem to swell appreciably with moisture content change, so volume has the advantage of being fairly indifferent to humidity, but the disadvantage that powder can pack tighter or looser, depending how carefully you operate your measure, and that bulk density of powder can vary as much as ±6% from lot-to-lot, so you have to check your recorded throw volume settings for each new lot of powder. Some are much more consistent than others.

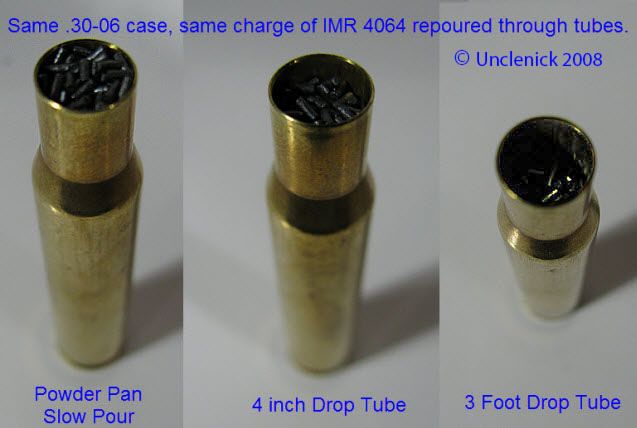

Then there is packing. Stick powder, in particular, can fall into a case with different stacking arrangements of the grains of powder. Spherical propellants pack much less, because spheres tend to stack the same way each time. Stick powder packing affects the ignition and practical burn rate of the charge. Two identical weight charges of stick powder can perform rather differently if one is tightly packed and the other is not. If dispensed by volume, however, the right stick powder in the right cartridge can actually self-compensate for the energy content error volumetric dispensing produces. That is, if there is an extra two percent of powder in a charge occupying the same volume as a 2% lighter charge due to tighter packing, it can tend to burn just enough slower that the bullet to winds up having the same point of impact.

Hatcher described an example he found developing a load for National Match ammunition one year (1920's; I suspect 1929 and comparing that year's IMR1185 and 1186, but Hatcher didn't say). He had two stick powders with burn rates he said were close to that of the more modern IMR4320. One had a short stick grain that the arsenal loading equipment metered (volumetrically) to a precision of 0.6 grains variation (±0.3 grains). The other had a long stick the equipment could only meter to a precision of 1.7 grains (± 0.65 grains) variation. Nonetheless, the cartridges loaded with that more widely varying charge of long grain powder proved consistently more accurate and Hatcher reported several records were broken with it at the National Matches that year.

IMR1185 had the same grain dimensions IMR4895 does today. IMR1186 had the same grain dimensions IMR4064 does today. So if I suspect the year correctly, the way IMR4064 packs today would be about the same as then. I note that in later years IMR1185 was used in NM ammo again, so this behavior was apparently affected by lot characteristics. Keep in mind they would have been loading with bulk grade powders that have wider burn rate variation from lot-to-lot than canister grade powders sold to handloaders today have.

Fastest burn rate<------------------------------------------------------->Slowest burn rate

Another factor is that some powders in some loads have their burn rate less affected by pressure than others in some conditions. For example, from Hodgdon's data, IMR4895 in the 308 pushing a 150 grain bullet produces 61.5 fps change in velocity per grain of powder error over its listed load range. Varget, on the other hand produces only 49.6 fps change in velocity per grain of powder error over its listed load range, making IMR 4895 is 124% more velocity sensitive to charge weight error. But put the same bullet in the 30-06 and it's the Varget that produces more variation 41.8 fps/grain vs. 38.3 fps/grain for IMR4895, or about 9% more charge weight velocity sensitivity in Varget.

That is, by the way, something you may find worth testing in your own gun under your typical use conditions with your particular bullet. Get a mean velocity for ten shots of your maximum load and drop it a grain and then get the mean velocity of another ten shots. Repeat with any other powder you are considering using. Compare the difference. The one with the smallest difference will tend to be the least sensitive to changes in conditions and to charge weight error. Keep in mind this is different for different bullet weights, as well.