You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hornady new primer tube filler finally available

- Thread starter Real Gun

- Start date

I too have been on reloading forums since '98. This discussion about primer tube blow-ups happens a lot. Usually it boils down to someone being stupid.

One I remember was some dope replacing the very light weight follower in a dillon 650 priming system with a piece of bronze rod long enough to allow all 100 primers feed. He said he was having problems with them dropping with the original follower. What happened? He lost his grip on that heavy rod, dropped it on a half full primer supply tube. BOOM!

I'd bet that most of the others are from some gorilla getting mad at some hang-up on the machine, then slamming the op handle. IF that hang-up was a primer going in wrong, it could trigger an explosion.

I never bought into the myth of there being primer "dust" present in a priming system. The primer pellet goes into the cup wet, with a paper disc on top of it. The paper disc is to keep the wet pellet from sticking to the punch. Then the anvil is placed on top of the disc. Finally is a layer of wet lacquer,(a type of paint), a sealer.

Now just how does that primer pellet that goes in wet and is formed perfectly to the bottom of the cup, going to form dust?

The way primers are packaged is to prevent them from touching. It's also to minimize vibration in transit.

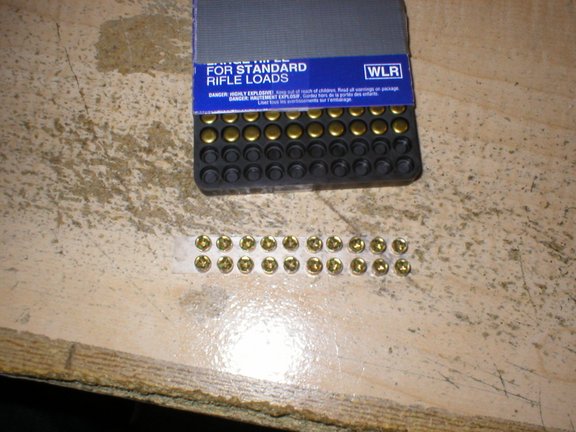

This discussion came up once on another forum. I decided to prove or disprove whether dust could be generated from a box of primers (100). Now what could provide vibration??¿¿ How about taping said box of primers to the lid of my FA vib tumbler? Viola! How long, well how about 3 hours, what it would take to do a batch of brass. Primers were inspected with a 20X magnifier before and after vibrating. No sign of dust. Ummmm, of yeah those were Winchester large rifle primers, standard, not magnum.

No, I didn't do any other types or manufactures. Visual inspection of wolf primers makes me think maybe they've skipped the lacquer sealer. maybe I should repeat my test with them?

Clean as a whistle!

One I remember was some dope replacing the very light weight follower in a dillon 650 priming system with a piece of bronze rod long enough to allow all 100 primers feed. He said he was having problems with them dropping with the original follower. What happened? He lost his grip on that heavy rod, dropped it on a half full primer supply tube. BOOM!

I'd bet that most of the others are from some gorilla getting mad at some hang-up on the machine, then slamming the op handle. IF that hang-up was a primer going in wrong, it could trigger an explosion.

I never bought into the myth of there being primer "dust" present in a priming system. The primer pellet goes into the cup wet, with a paper disc on top of it. The paper disc is to keep the wet pellet from sticking to the punch. Then the anvil is placed on top of the disc. Finally is a layer of wet lacquer,(a type of paint), a sealer.

Now just how does that primer pellet that goes in wet and is formed perfectly to the bottom of the cup, going to form dust?

The way primers are packaged is to prevent them from touching. It's also to minimize vibration in transit.

This discussion came up once on another forum. I decided to prove or disprove whether dust could be generated from a box of primers (100). Now what could provide vibration??¿¿ How about taping said box of primers to the lid of my FA vib tumbler? Viola! How long, well how about 3 hours, what it would take to do a batch of brass. Primers were inspected with a 20X magnifier before and after vibrating. No sign of dust. Ummmm, of yeah those were Winchester large rifle primers, standard, not magnum.

No, I didn't do any other types or manufactures. Visual inspection of wolf primers makes me think maybe they've skipped the lacquer sealer. maybe I should repeat my test with them?

Clean as a whistle!

Was there a point in this thread when someone actually made a connection between these vibratory primer tube fillers and tubes detonating, or did someone just mention primers and someone's button got pushed?

None that I know of, just dislike for tube fed machines in general.

I did point out that Dillon's vibratory tube filler does include a blast shield but have never heard of one going off (unlike folks hammering one off in presses).

Last edited:

schmellba99

New member

You guys are saying, since a tube never exploded in your experience, it's perfectly safe and never will happen.

I'm not saying that at all, nor am I saying that the protective blast sleeve is the "cure".

I'm saying that tube fed systems, while not perfect, have such a small chance of anything going wrong outside of operator error that you are effectively worrying about something with a near zero percent chance of happening. And there's nothing wrong with that, so long as you realize that with the overwhelming majority (I'd venture to say something on the order of 99.9999999999%) of any accident associated with a primer detonating in a tube system is wholly attributed to operator error. And even experienced operators can make an error.

The blast sleeve is strictly a safety measure, no different than good practices like wearing hearing protection when you shoot.

There does not need to be an absolute - there are never absolutes.

I'm saying that tube fed systems, while not perfect, have such a small chance of anything going wrong outside of operator error that you are effectively worrying about something with a near zero percent chance of happening.

I guess that is where I was going but there are still people that can't drink coffee without getting hurt.

https://en.m.wikipedia.org/wiki/Liebeck_v._McDonald's_Restaurants

Some of them may think reloading is like putting popcorn in a microwave and hitting the "popcorn" button. This is where we get "kaboom" threads, guns, primer tubes, etc.

I know car crashes have killed (millions more injured) more than 3.5 million people in the U.S. but I still drive.

Know the risks, weigh them vs the rewards and make your choice. I am as happy with your choice as I am mine and happy both of our choices have been successful for us.

I agree.....you know, adults have the right to take risks. Extreme Sports is certainly an example.

I almost used car crashes in the last post.....then thought better.....and here you said what I thought you'd say without me posting that. Mind reader you are!

I'm much older and wiser (and still here) these days, and I am super glad they didn't stop improving car suspensions, and crash safety features back in 1968. (especially since now days,if you go 70 on some freeways, you are going to get run over.)

My point is people who have these accidents aren't nearly as stupid as I was back in 1968, but they ought to at least know the score. Most didn't even know that primers could blow up in a chain reaction, a 100 at a time. Where's the "decision" in that. At least this thread and others points that out. I also am glad we (for a while yet) have the right to decide for ourselves.....just be wise and take off the blinders, all.

Last edited:

Some of them may think reloading is like putting popcorn in a microwave and hitting the "popcorn" button. This is where we get "kaboom" threads, guns, primer tubes, etc.

There are clearly some people that should never attempt to reload. It takes attention to detail, the ability to follow a recipe/plan, great care and caution to do things right. There's no place for anger or short fuses that could cause an outburst of slamming the operators handle/ram arm on a reloading machine because something is hanging it up. Take time out to investigate what just went wrong, then solve the problem.

Get used to how the machine sounds when it's working right. If something just went wrong, it'll make a different sound. having a radio playing is something a lot of us do, but it can mask sounds from the machine that could alert you to a potential mistake.

My Dillon 650 has a very unique sound as it cranks out each shell. I call it Dillon music, or another phrase I use, it sounds like money--Saved--. Once in a while the case feeder gets jammed, that whir it makes as it drops the next empty shell is missing right away.

cryogenic419

New member

Ordered one of these recently. The on off switch that is tied to the blast shield feels cheap and I don't see it lasting very long. Small primers seemed to feed ok for the most part, took about 20 seconds or so to fill the tube. Large primers did not go as quickly. Took about a minute of shifting the primers around back and forth to get them all down the tube. Almost seems like the hole in the plastic tray is too tight. Primers still make it through but they have to align with the hole just so. I am hoping that with a little bit more use things will break in a little and go smoother. Still faster than pecking them out of a tray.

No idea on battery life as I've only run about 800 primers through it so far, but have not noticed any degradation in vibration yet. A little pricey for what it is but if you are trying to hammer out a lot of ammo fast this will save you time and is definitely cheaper than the Dillon.

No idea on battery life as I've only run about 800 primers through it so far, but have not noticed any degradation in vibration yet. A little pricey for what it is but if you are trying to hammer out a lot of ammo fast this will save you time and is definitely cheaper than the Dillon.

I have loaded up one tube of small primers so far and found the angle at which you tip the tray toward the tube hole is important.

Right away, I find a need for a plug, so I can store a tube of primers. My press was not yet ready for a refill, and there should be a way to have a couple tubes loaded ahead. I may drill the end and use one of the spare pins, so the tube can be dismounted from the grip without spilling primers all over the room. Then I will have to color one of the tube ends so I know which end to pour.

Right away, I find a need for a plug, so I can store a tube of primers. My press was not yet ready for a refill, and there should be a way to have a couple tubes loaded ahead. I may drill the end and use one of the spare pins, so the tube can be dismounted from the grip without spilling primers all over the room. Then I will have to color one of the tube ends so I know which end to pour.

Holding them "just right" is the key to getting the best results and a little "twitch" when one won't drop.

This is the technique I use with the less expensive vibraprime.

https://www.youtube.com/watch?v=0WTZ-_v6Mks

This is the technique I use with the less expensive vibraprime.

https://www.youtube.com/watch?v=0WTZ-_v6Mks

cryogenic419

New member

Hornady is marketing this as you hold it like a gun and its at the optimum angle...its not. Watched your video and found myself doing the same thing, slight angle and giving the whole unit a little jerk from time to time.

Like I said this is better than pecking them up one by one, and if you're trying to crank out ammo it really is saving a ton of time, just pricey for what it is.

Like I said this is better than pecking them up one by one, and if you're trying to crank out ammo it really is saving a ton of time, just pricey for what it is.

just pricey for what it is.

I think we can stop apologizing for what we spent. I am glad to have it. I would have spent quite a bit more to be able to stop picking up primers one by one or messing with primer boxes that are bigger than the tray.

I'm glad it's working for you guys. The FA unit never worked for me. I tried three different ones. I finally bought the Dillon RF-100 and it has worked for me since. I'm not going to apologize for spending what I did on it either. I too got tired of flipping and pecking primers.

I had an old VP but when they stopped making it they were selling for insane prices, so I sold mine (for way too much money) and bought the Dillon filler.

Then they started making them again and even had a sale on the VP for $25/ea. I couldn't resist picking a few up at that price. They are not a "hold and pull the trigger" device. However, if you take a few minutes to learn what makes them not work, you can save quite a bit of time down the road. Hard to beat 100 primers in the flipper to tube in under 20 seconds.

Then they started making them again and even had a sale on the VP for $25/ea. I couldn't resist picking a few up at that price. They are not a "hold and pull the trigger" device. However, if you take a few minutes to learn what makes them not work, you can save quite a bit of time down the road. Hard to beat 100 primers in the flipper to tube in under 20 seconds.

My problems were not that they would not put primers in the tube. It was that I averaged 7 to 10 upside down primers in every tube. I tried many solutions I read about on various forums with no luck. With the Dillon filler I still get upside down primers, but the average has dropped to 1 in 1000. That is acceptable.

My problems were not that they would not put primers in the tube. It was that I averaged 7 to 10 upside down primers in every tube. I tried many solutions I read about on various forums with no luck. With the Dillon filler I still get upside down primers, but the average has dropped to 1 in 1000. That is acceptable.

That might not be pertinent to this unit from Hornady. I would expect designers to address problems known in earlier devices. On my new Hornady, the primers are covered so close that they cannot flip while in the tray. Something would have to happen at the hole for the tube, but that is closely covered too..

OK. Being a silly gadget person. I bought one the the Hornady units. The Hornady unit performed flawlessly with small primers. 0 flipped primers there. Large primers is another story. Wolf brand large pistol primers would not feed at all with out constant firm thumps on the top of the handle unit. I only had 1 other brand of large primers, so I tried those. They were CCI large rifle primers. Those fed mostly ok but still require firm thump on top of the handle unit, but not as often as the others. Only 1 flipped primer in 200 and I'm not sure I got that one flipped correctly in the tray before I put the cover on. The large rifle primers were taller than the large pistol primers and would get caught up in the middle of the tray.

Over all my comparison of the 2 units is the Hornady unit is much better functionally, but neither unit is made of materials for longevity. They both have a cheap plastic feel. The hornady units large primer tray was quit fiddly trying to get it mounted on the handle. The small tray went right on.

I am going to call Hornady and talk to them about my problems with the large primer tray and difficulty of feeding. We'll see how this goes.

Over all my comparison of the 2 units is the Hornady unit is much better functionally, but neither unit is made of materials for longevity. They both have a cheap plastic feel. The hornady units large primer tray was quit fiddly trying to get it mounted on the handle. The small tray went right on.

I am going to call Hornady and talk to them about my problems with the large primer tray and difficulty of feeding. We'll see how this goes.

I also use the primer tube process on my Hornady LNL AP. The obvious weakness to me in this process is in transferring the primers inside the filled pickup tube to the primer tube setting inside the blast shield. I can see me dropping this tube moving from the primer tray after picking up 100 primers and it going off. I think once the primers are safely transferred to the primer tube inside the blast shield, there is much less risk of an explosion. The second part of this risk is releasing the hitch pin when the filler tube is setting on top of the primer tube and letting 100 primers slide down to the bottom of the primer tube. The tubes are made to tight tolerances and escaping air around the falling primers cushions and slows the fall of the primers. Safety goggles are a must when doing this.