You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Golden Saber 9mm test

- Thread starter Lurky BoDean

- Start date

If this is interesting, I kept some images from a Rem gel shoot event a few years ago ...

For the purpose of this thread topic, these are just the Golden Sabre BJHP and Bonded rounds (not everything else).

Rem standard 180 gr BJHP (non-bonded) .40 fired through 4-layers of denim into a gel block (P229 used). Seemed to do okay.

At the end of the day for that gel event, the rep fired 5 rapid shots into a gel block, achieving 5 nicely expanded bullets that penetrated just about within 2-3 inches of each other. Not bad, I'd think.

Now, here's a bonded Rem 180gr .40 BJHP bullet that was fired into the same denim barrier/gel conditions. A little different expansion for that shot using the bonded bullet.

Here's the standard non-bonded round fired through auto windshield type glass into gel.

And here's the bonded bullet fired through glass into gel.

While nobody offers a guarantee for expansion, penetration and overall "performance" when it comes to defensive loads, when I use Rem Golden Sabre BJHP ammo, I'm satisfied using the standard non-bonded loads such as the 124gr +P 9mm, 180gr .40, 230gr .45 ACP, & 125gr .38 +P. Not so much the 165gr .40 loads.

It's not the only type of defensive ammo I use and carry, though, nor do I consider it to necessarily be "the best". (I also use Win T-series, Speer GDHP and occasionally even some other old-style hollowpoint loads, depending on availability.)

I use the Rem BJHP when it's on hand (issued), and focus more attention on whether it actually feeds & functions in my guns, and definitely more thought to my skillset and weapon maintenance practices.

FWIW, the Rem rep explained during the event that Rem "bonds" their BJHP bullets by putting flux compound inside the brass jacket before the lead ingot (core) is inserted and the bullet's production completed. he said they also make subtle changes to the nose cavity/hollowpoint shape which are intended to prevent the the jacket from expanding too rapidly, and that these design changes vary according to caliber & bullet weight.

For the purpose of this thread topic, these are just the Golden Sabre BJHP and Bonded rounds (not everything else).

Rem standard 180 gr BJHP (non-bonded) .40 fired through 4-layers of denim into a gel block (P229 used). Seemed to do okay.

At the end of the day for that gel event, the rep fired 5 rapid shots into a gel block, achieving 5 nicely expanded bullets that penetrated just about within 2-3 inches of each other. Not bad, I'd think.

Now, here's a bonded Rem 180gr .40 BJHP bullet that was fired into the same denim barrier/gel conditions. A little different expansion for that shot using the bonded bullet.

Here's the standard non-bonded round fired through auto windshield type glass into gel.

And here's the bonded bullet fired through glass into gel.

While nobody offers a guarantee for expansion, penetration and overall "performance" when it comes to defensive loads, when I use Rem Golden Sabre BJHP ammo, I'm satisfied using the standard non-bonded loads such as the 124gr +P 9mm, 180gr .40, 230gr .45 ACP, & 125gr .38 +P. Not so much the 165gr .40 loads.

It's not the only type of defensive ammo I use and carry, though, nor do I consider it to necessarily be "the best". (I also use Win T-series, Speer GDHP and occasionally even some other old-style hollowpoint loads, depending on availability.)

I use the Rem BJHP when it's on hand (issued), and focus more attention on whether it actually feeds & functions in my guns, and definitely more thought to my skillset and weapon maintenance practices.

FWIW, the Rem rep explained during the event that Rem "bonds" their BJHP bullets by putting flux compound inside the brass jacket before the lead ingot (core) is inserted and the bullet's production completed. he said they also make subtle changes to the nose cavity/hollowpoint shape which are intended to prevent the the jacket from expanding too rapidly, and that these design changes vary according to caliber & bullet weight.

Last edited:

KyJim

Mine was shot into wet pack,Not very scientific but I take shreaded news paper put it jugs fill with water and let stand 24 hrs.

Its pretty dence.I did not have as many seperate using denim and water.

These were hand loads running a little over 1200 fps.not factory.

I use this to test different bullets in the same media just as a comparison.

This time it was the 124gr.Gs,Gold Dot,and the xtp.The results were very different using just water.

Mine was shot into wet pack,Not very scientific but I take shreaded news paper put it jugs fill with water and let stand 24 hrs.

Its pretty dence.I did not have as many seperate using denim and water.

These were hand loads running a little over 1200 fps.not factory.

I use this to test different bullets in the same media just as a comparison.

This time it was the 124gr.Gs,Gold Dot,and the xtp.The results were very different using just water.

I don't know if the GS are the best SD, but they are certainly good and they are more reasonably priced.

I believe that in this case factory ammunition's more reliable than hand loads, so that's what I stock in the gun.

As stated, they are very accurate.

I am reloading Hornady XTP for practice which are proving to be very accurate (and cost is $15 a hundred so when reloaded its as low cost as cheap rounds). I like to stay as close as I can go the GS as while the range is fun shooting and target as well, ultimately its all about SD.

Also they are interesting as they are a bore ride design. My brother and I are playing with them re-loading wise as they are a bit tricky to reload with that drive band in the end, crimps or lack there off etc.

There is very little re-load data on these rounds. A lot of it is mis stated. My take is they should be loaded down as they have less friction and will achieve the same speed at lower loadings.

And 124 gr is considered the right gr for the 9mm. You need to hit 1000 fpm to have reliable expansion and the 147s come up a bit short. Close enough at a listed 980 that sometimes they do and sometime they do not.

I believe that in this case factory ammunition's more reliable than hand loads, so that's what I stock in the gun.

As stated, they are very accurate.

I am reloading Hornady XTP for practice which are proving to be very accurate (and cost is $15 a hundred so when reloaded its as low cost as cheap rounds). I like to stay as close as I can go the GS as while the range is fun shooting and target as well, ultimately its all about SD.

Also they are interesting as they are a bore ride design. My brother and I are playing with them re-loading wise as they are a bit tricky to reload with that drive band in the end, crimps or lack there off etc.

There is very little re-load data on these rounds. A lot of it is mis stated. My take is they should be loaded down as they have less friction and will achieve the same speed at lower loadings.

And 124 gr is considered the right gr for the 9mm. You need to hit 1000 fpm to have reliable expansion and the 147s come up a bit short. Close enough at a listed 980 that sometimes they do and sometime they do not.

5R milspec

New member

I will soon find out for myself for I just bought and loaded up 100 rounds.( golgen saber 124gn )my loads are not runnung as fast as yours but think they will do just fine.now my family just needs to drink or use up alot of milk.

as soon as I can do the testing I'll post on your forum if thats OK.I will even test some of the XTP's I have loaded along with other bullets.I too have the older or old style HP that remington offers to try.will just have to see want we.

as soon as I can do the testing I'll post on your forum if thats OK.I will even test some of the XTP's I have loaded along with other bullets.I too have the older or old style HP that remington offers to try.will just have to see want we.

Lurky BoDean

New member

5R Milspec feel free to post up your results. Also if you have the regular 124gr, then we have the same round. My bullets are NOT +P. I can't wait to see your results. I plan on purchasing another box of this stuff soon.

God bless

God bless

The problem with the GS is that you have the drive band and then a blank space that is sub diameter above that.

You can't crimp it as you are crimping on the sub diameter bore ride.

Seems to work ok without, just odd. Not much and likely not a problem but an odd one.

I miked a box of the 147s for length. They seem to be about 1.140 length average. Bullets are a bit hard to read due to the slightly uneven ends. XTPs are 1.100

I think the 124s mike about 1.128 (though I have one that is 1.215. That is longer than the Hornady XTP 124 at 1.060.

You can't crimp it as you are crimping on the sub diameter bore ride.

Seems to work ok without, just odd. Not much and likely not a problem but an odd one.

I miked a box of the 147s for length. They seem to be about 1.140 length average. Bullets are a bit hard to read due to the slightly uneven ends. XTPs are 1.100

I think the 124s mike about 1.128 (though I have one that is 1.215. That is longer than the Hornady XTP 124 at 1.060.

5R milspec

New member

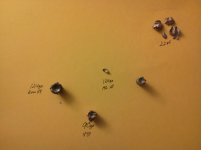

OK me and the kids put together three jugs.we all so got to shoot today but had problems from the word go.my mistake was shooting the jugs more than ounce.BUT we did end up with three bullets to go from.one is a plain old remington HP at 124gn.one is a 124gn montana gold HP and the other was a 90gn XTP from a 380.

the plain 124gn HP did OK but not something to write home about.the montane gold just did open and the jacket came right off.the 90gn XTP from the 380 just did open keeping the jacket.we never did find the one BULLET we wanted to see which was the golden saber.so now my kids and I have to put away alot more milk to test again.I have pics of the three bullets we did end up with but my wife will have to post them.sorry about that part but will get them posted asap.

hey my golden sabers are what I ordered from midway.they had BJHP on the box.I loaded them with 4.6gn of HP38 and a case over all length of 1.140.I cannot say to how fast they are for I have no chrony to check with.QL says they are running 1057 fps.but will say they felt good when I shot them.the primer even looked good to the eye.I hope to redo the test soon but if you have any idea to what can help me out please say so.went out on a limb this time for a test.I had three jugs in a row taped togther and was 20 feet away from them when I shoot.as I said above I shoot eight times useing 4 different bullets.think I should have just fired the two golden sabers and stoped.

the plain 124gn HP did OK but not something to write home about.the montane gold just did open and the jacket came right off.the 90gn XTP from the 380 just did open keeping the jacket.we never did find the one BULLET we wanted to see which was the golden saber.so now my kids and I have to put away alot more milk to test again.I have pics of the three bullets we did end up with but my wife will have to post them.sorry about that part but will get them posted asap.

hey my golden sabers are what I ordered from midway.they had BJHP on the box.I loaded them with 4.6gn of HP38 and a case over all length of 1.140.I cannot say to how fast they are for I have no chrony to check with.QL says they are running 1057 fps.but will say they felt good when I shot them.the primer even looked good to the eye.I hope to redo the test soon but if you have any idea to what can help me out please say so.went out on a limb this time for a test.I had three jugs in a row taped togther and was 20 feet away from them when I shoot.as I said above I shoot eight times useing 4 different bullets.think I should have just fired the two golden sabers and stoped.

Attachments

Last edited:

That's interesting. If you go back and read up on the original FBI selection process that led to the adoption of the Springfield Pro, they required the test guns meet specific accuracy requirements using the Golden Sabers. I think it was Bill Wilson who thought the round did not possess enough inherent accuracy to be able to meet that requirement. To their credit, SA met it.FWIW the Golden Sabers in the 230gr are the most accurate factory rounds in my SR1911 and Springfield 1911

The GS was very very accurate with the Sig.

Same with my brothers HK.

Frankly I think its an inherently accurate setup. No one else does the bore ride design.

Loading up some 147 gr ones to crony this weekend with HS-6. I have speed data for XTP 147 so will see how it correlates. I think it will move faster with a given charge due to less friction. Will see.

Same with my brothers HK.

Frankly I think its an inherently accurate setup. No one else does the bore ride design.

Loading up some 147 gr ones to crony this weekend with HS-6. I have speed data for XTP 147 so will see how it correlates. I think it will move faster with a given charge due to less friction. Will see.