I rather doubt it since a blow to the receiver hard enough to break a brittle receiver could be hard enough to inflict permanent damage on a good one.

The best article I have seen on the brittleness of these early 03’s is Rifle Magazine, May-June 1985 About Low Number Springfields Sedgley’s and others. By Hugh Douglas.

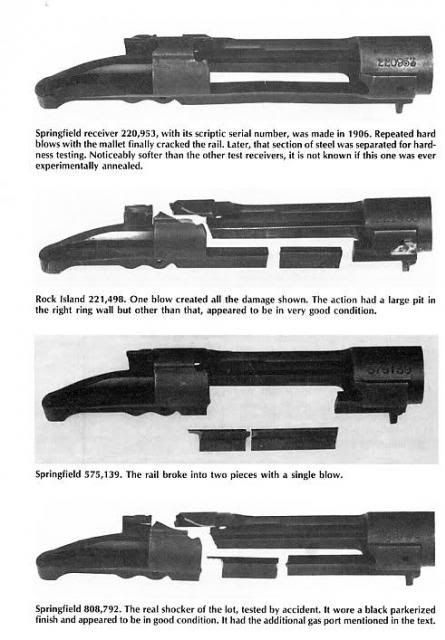

Hugh used a sample size of five low number and one “high number” 03 receivers. He held one in his left hand, his right hand held an eight ounce nylon faced hammer, and drawing the hammer back 18”, he struck the receiver siderail. All of the receivers, including the 808,000 receiver shattered. He had the pictures in the article.

Previous to this article, he purchased a 600,000 1942 rebarrel, but it had a small crack on the receiver. Laying the thing on his kitchen table he “

impulsively, I lightly tapped the bridge with a 5/8” open end wrench. The crack now went all the way from front to rear of the bridge. “What the hell!!”. Wielding the small wrench a little harder, I struck the rifle rear bridge and it broke off flush with the bolt raceway. The metal along the broken edges looked like a broken cast iron casting. Using the wrench I proceeded to break the action into pieces until finally there was only an irregular piece of the receiver ring attached to the barrel. Several hard blows and the shattered receiver ring dropped off the barrel. “

If tapping the receiver with a hammer is obviously too much, then get a 5/8” open end wrench and hit the thing. Or, drop it on the floor, as I have read of single heat treat receivers shattering on a concrete floor.

I remember an account from the old Culver’s forum and one poster just tapped his single heat treat and it fell into pieces.

These receivers were weak, their billets had been burnt in the forge room, this was a well known issue at the time, well known enough that even as late as 1948 there is a section in the American Society of Metals Handbook about burnt forge billets. “

Burning is an extremely overheated condition that causes the more fusible constituents of the steel to melt….results in hot shortness of the material… This is evident since steel that is burned entirely on the inside, may appear quite satisfactory on the surface.

Springfield Armory had not equipped their forge room with pyrometers, and there may have been the perverse incentive of piece part payment. If they paid their forge workers based on piece part, it would have been to their advantage to heat the billets to as hot a temperature as possible as it would have made stamping the parts quicker. Regardless, given that Springfield was behind the time in pyrometers, it is no wonder that billets were burnt.

Hatchers shifts the blame onto the forge shop workers, as if their suspicion of pyrometers and new technology had anything to do with Army management not installing pyrometers. People today are laid off all the time with labor saving technology, but back then, there was no such thing as welfare or unemployment compensation, so it is certain that the forge shop workers were not eager to embrace change. But, they are not the people running the Armory, the Colonel is running the Armory, and the Green suiters were having a great time playing polo on the parade ground, and were ignoring what was going on inside their factory. After all, who the heck was in charge of Springfield Armory? This is another great Hatcher misdirection, you don’t even understand how or why you think the forge shop workers created this situation. They did not, all the forge shop workers did were to stamp out parts following the work instructions put in place by the plant managers on the equipment provided by the plant managers. It just so happens that the plant managers were Regular Army officers. If the forge shop workers did not have pyrometers then it is the fault of the Army, not the consequence of some fictitious labor dispute.

Hatcher is a great magician, he displays a shiny thing, makes a hand flip, Hatcher plays the misdirection so well that no one ever finds the Army under any of his three monte cards.