Kucka 2004,

Do the cases get stuck before firing, so they can't be ejected unfired, or are they stuck after firing? Stuck after firing is a high pressure sign.

If they are getting stuck before firing or during loading, then you are not resizing the cases enough to fit your gun.

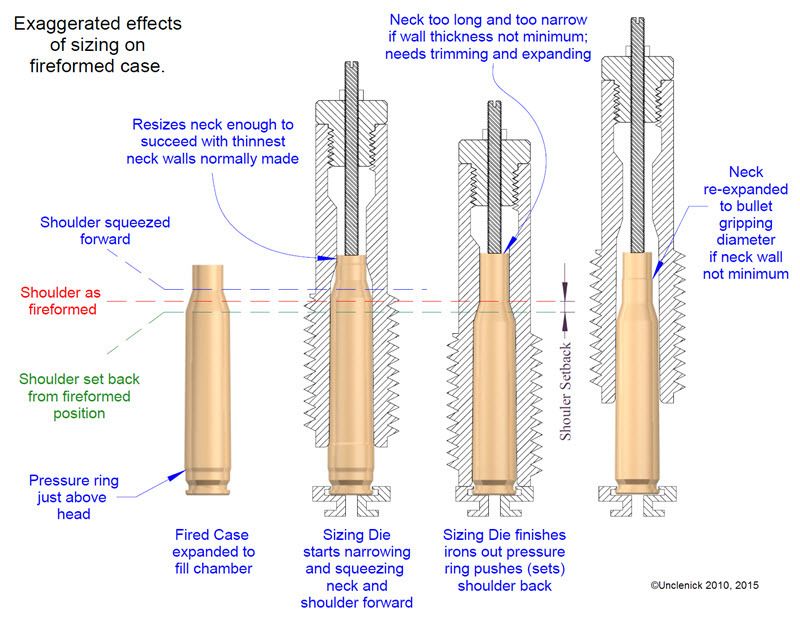

So my first question is, do cases from new commercial ammunition that are fired in your gun fit the Wilson gauge before you resize them? In other words, are they sticking out more after resizing than the do before resizing? If so, it means the die is not pressing against the shell holder hard enough during resizing. I say this because with most bottleneck rifle cartridges, there is contact made with the sides of the case and die first. This narrows and lengthens the case. Only after the die shoulder makes contact with the case shoulder does it start to move the shoulder back and flow the excess brass into the neck, which is what grows the case.

Improper sizing die is common among folks new to reloading (I don't know if you are). What happens is the sizing force stretches the press slightly. As a result, even though the die was in contact with the shell holder when you set it up, when you actually have a case in it and forced up to maximum a crack of light can be seen between the case mouth and the top deck of the shell holder. To prevent this you have to compensate by turning the die down a little at a time until it disappears. Usually a quarter turn beyond contact will do it for a heavy cast iron press. With an aluminum press like some of the Lee presses, it's modulus of elasticity is lower, so it stretches more easily, and you may need as much as 3/4 turn extra.

Lee's help video on setting up a sizing die shows how to do this for an aluminum press and how to check for the crack of light. For an iron press, just figure about 1/3 as much extra turn after finding the contact point.

If you want, you can also try Mr. Guffey's trick of removing your decapper and sliding a feeler gauge into the shell holder under the head of the case. This will cause it to be resized further by the thickness of the feeler gauge. You will, however, have to return the expander and run the case over just that part as a second operation afterward, or the neck will come out too narrow, making bullets harder to seat straight.