You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Early 03 receiver question

- Thread starter sp45

- Start date

The Early Rock Island Recievers are not worth very much, as it is recomended not to shoot them, as the heat treating was not properly done and they have the potential to blow up in your face.

Therefore no one would want one to make a Custom Sporter rifle out of them for that reason. Sorry.

Most of those guns are recomended for display purposes only.

Therefore no one would want one to make a Custom Sporter rifle out of them for that reason. Sorry.

Most of those guns are recomended for display purposes only.

The only way to truly know is to put the receiver on an auction site.

TX Hunter's analysis is correct though, low number receivers have a poor reputation. Some were burnt in the forging process and many shattered in use, or just from hitting the floor. There is no non destructive test to sort the good from the bad, so as a group, all the 1,000,000 low number receivers have a bad reputation.

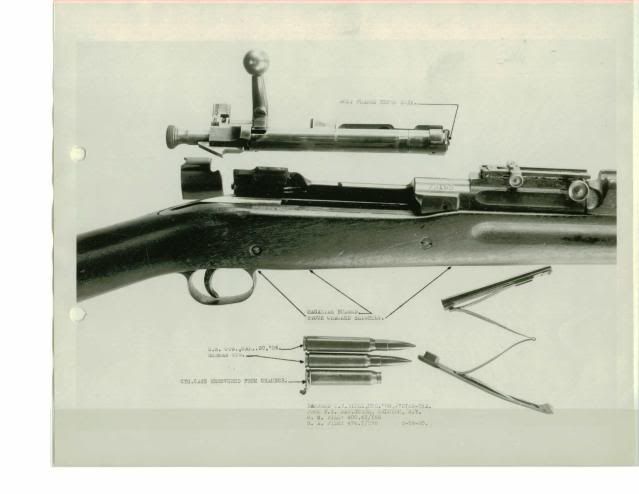

Of course not all 1,000,000 are brittle. But even so, these single heat treat receivers were made from plain carbon steel that today is used for rebar. Even if they were properly made there is no margin of strength in an accident and when they blow, they fragment. Such as the receiver blown up with a double charge of H4227 and I assume, lead bullets.

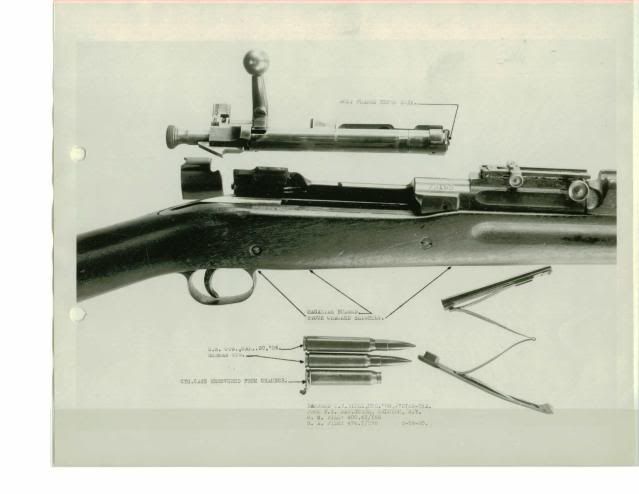

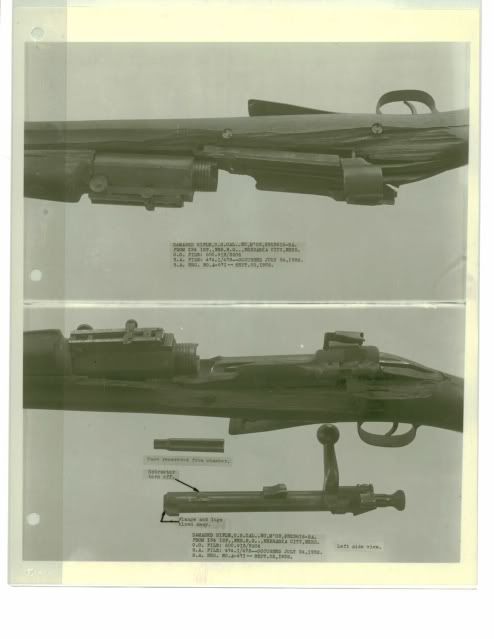

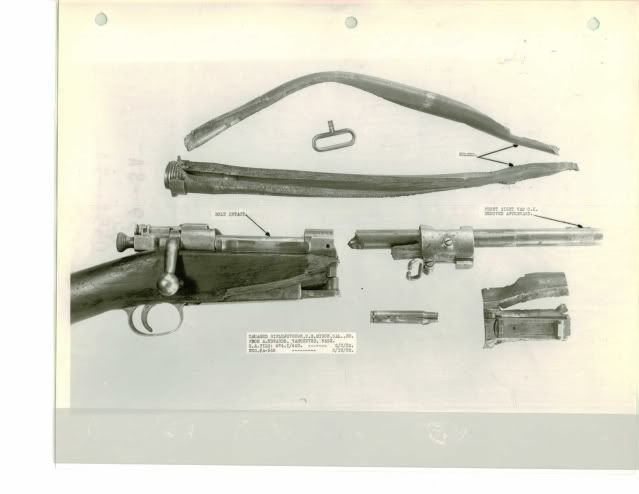

Cracked Low number CMP receiver, picture from Old Jouster.

Low number receiver shattered with double charge of H4227

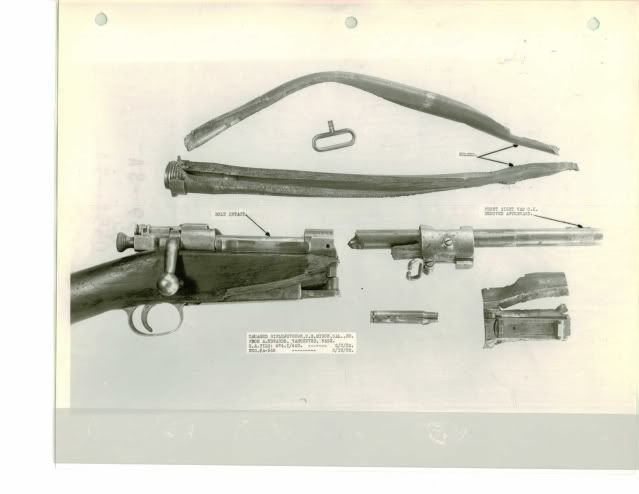

Your receiver would have tremendous value if it were only attached to all the original rod bayonet parts. But those parts are missing. I can only imagine that the cost of building an all correct rod bayonet rifle is hideously expensive. I suspect a correct rod bayonet stock is much more valuable than your receiver.

TX Hunter's analysis is correct though, low number receivers have a poor reputation. Some were burnt in the forging process and many shattered in use, or just from hitting the floor. There is no non destructive test to sort the good from the bad, so as a group, all the 1,000,000 low number receivers have a bad reputation.

Of course not all 1,000,000 are brittle. But even so, these single heat treat receivers were made from plain carbon steel that today is used for rebar. Even if they were properly made there is no margin of strength in an accident and when they blow, they fragment. Such as the receiver blown up with a double charge of H4227 and I assume, lead bullets.

Cracked Low number CMP receiver, picture from Old Jouster.

Low number receiver shattered with double charge of H4227

Your receiver would have tremendous value if it were only attached to all the original rod bayonet parts. But those parts are missing. I can only imagine that the cost of building an all correct rod bayonet rifle is hideously expensive. I suspect a correct rod bayonet stock is much more valuable than your receiver.

It might be worthwhile to check out Culvers Shooting Page forums at http://www.jouster.com/forums/. They have a very active M1903 community.

low numbers

"many shattered in use"

The original study as summarized by Julian Hatcher in his "Notebook" indicated that by the time of recall (about 1929-1930, after a war and more than 25 years of production) there had been 70 documented failures out of more than a million guns. Since that time....I don't know.

The problem, though, about the receivers failing is the nature of the failure not just that it did. That photo of the double charge of 4227 is a good example. Very probably a double heat treated "acceptable" high number made after 1919 receiver would have failed from such a load. But the low numbered receivers shatter, the stronger receivers don't; they may warp and stretch and crack but they generally don't become shrapnel.

Pete

"many shattered in use"

The original study as summarized by Julian Hatcher in his "Notebook" indicated that by the time of recall (about 1929-1930, after a war and more than 25 years of production) there had been 70 documented failures out of more than a million guns. Since that time....I don't know.

The problem, though, about the receivers failing is the nature of the failure not just that it did. That photo of the double charge of 4227 is a good example. Very probably a double heat treated "acceptable" high number made after 1919 receiver would have failed from such a load. But the low numbered receivers shatter, the stronger receivers don't; they may warp and stretch and crack but they generally don't become shrapnel.

Pete

The serial number is below 1600...

Holy #$%@! That's low.

I guess not THAT low, but cool anyway (to me, lol).

Is there any kind of test a lab could do to examine the martensite/austenite structure of the metal and determine the safety that way?

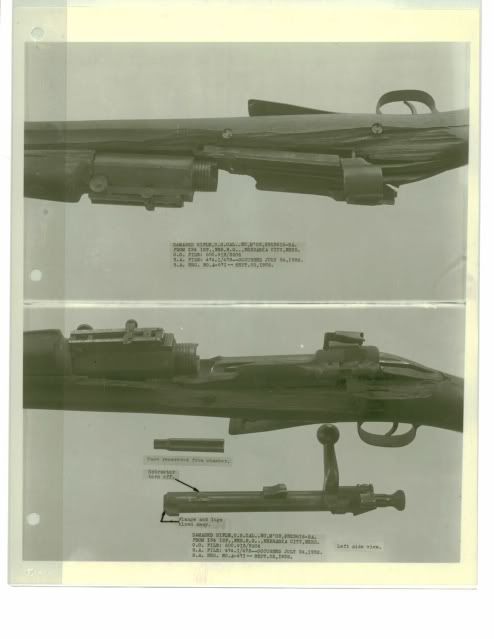

Here are some more LN shattered receivers, I believe these are after the reporting period in Hatcher's Notebook. Except for the 8mm Mauser blowup, he used that picture.

You can find more at the Springfield Armory Musuem site. It just takes forever to find and download them.

The analysis at "Some Observations On The Failure Of U.S. Model 1903 Rifle Receivers" is flawed. It is only based on the information presented in Hatcher's Notebook. Hatcher's database is incomplete.

These LN receiver can be so brittle that they will shatter with a sharp hammer blow. I hit my limit of eight pictures on this forum, so I cannot post the other two. This series of pictures was taken from the old CMP web page. The original thread is gone forever. But this LN receiver shattered when the owner hit it sharply with a hammer. Since the thread is gone, you can wonder how sharply, but as you can see , the receiver is in pieces, not flattened pieces either.

You can find more at the Springfield Armory Musuem site. It just takes forever to find and download them.

The analysis at "Some Observations On The Failure Of U.S. Model 1903 Rifle Receivers" is flawed. It is only based on the information presented in Hatcher's Notebook. Hatcher's database is incomplete.

These LN receiver can be so brittle that they will shatter with a sharp hammer blow. I hit my limit of eight pictures on this forum, so I cannot post the other two. This series of pictures was taken from the old CMP web page. The original thread is gone forever. But this LN receiver shattered when the owner hit it sharply with a hammer. Since the thread is gone, you can wonder how sharply, but as you can see , the receiver is in pieces, not flattened pieces either.

Last edited:

I feel very confident in saying that most low serial numbered M1903 receivers are safe to shoot. But I also feel just as confident in saying that there is no way to tell if a given low serial numbered M1903 receiver is a brittle receiver.

So, it's like playing roulette. If you bet on one number, you're likely to lose. But you still have a chance for the ball to drop on your number. Personally, I would not take the chance and I don't think that I'm being overly conservative - here's why:

Statistically speaking, any M1903 has a chance to fail in some way. The chance of a catastrophic failure, as a subset of any failure is pretty low, I suspect. Based on that supposition, I have no qualms about taking my M1903 out to the range for a day of blasting at targets (it happens to be a high serialed Springfield). I also know that it's an old rifle - the receiver was made in 1918 - so there is some increased potential for a failure to occur simply because of age and use. But, again, I believe that the potential for a catastrophic failure is vanishingly small.

My receiver is a known quantity: it's a high numbered model that has a well-established track record of not blowing up due to brittleness because it was manufactured using a quantifiable process. Now, if I put a low numbered receiver into my gun, I've increased the chances of a catastrophic failure because I know that it was not heat treated using a reliable, quantifiable process. By how much? I don't know - a specific shot from an individual receiver will either fail or it won't. But, like I said earlier, chances are that it won't. The problem is that the chance that a low numbered receiver won't fail isn't the same chance that a high numbered receiver won't fail. And with my face just inches from that receiver, I wouldn't feel confident in that chance.

So, it's like playing roulette. If you bet on one number, you're likely to lose. But you still have a chance for the ball to drop on your number. Personally, I would not take the chance and I don't think that I'm being overly conservative - here's why:

Statistically speaking, any M1903 has a chance to fail in some way. The chance of a catastrophic failure, as a subset of any failure is pretty low, I suspect. Based on that supposition, I have no qualms about taking my M1903 out to the range for a day of blasting at targets (it happens to be a high serialed Springfield). I also know that it's an old rifle - the receiver was made in 1918 - so there is some increased potential for a failure to occur simply because of age and use. But, again, I believe that the potential for a catastrophic failure is vanishingly small.

My receiver is a known quantity: it's a high numbered model that has a well-established track record of not blowing up due to brittleness because it was manufactured using a quantifiable process. Now, if I put a low numbered receiver into my gun, I've increased the chances of a catastrophic failure because I know that it was not heat treated using a reliable, quantifiable process. By how much? I don't know - a specific shot from an individual receiver will either fail or it won't. But, like I said earlier, chances are that it won't. The problem is that the chance that a low numbered receiver won't fail isn't the same chance that a high numbered receiver won't fail. And with my face just inches from that receiver, I wouldn't feel confident in that chance.

Gunplummer

New member

Receiver Material

I keep seeing reference to case hardened "rebar like material" in '03 Springfields.I am not picking on anybody, but where did this idea come from? I never worked on an '03, the reputation being so bad I refused to. The description of failure sounds like improper heat treating of chrome moly or nickel steel. Mausers, Russians, Carcanos are all cased with junk under them and you don't hear to many stories about receiver failure with them. I recently had a lively discussion about color casing 99 savage receivers. That would react like the description of failure you are talking about, through and through over hardness. Fortunately, most 99s are low pressure rounds and I never heard about any thing bad happening because of it. Like I said, I don't work on '03s, but I used to heat treat a lot of gun parts and I am curious.

I keep seeing reference to case hardened "rebar like material" in '03 Springfields.I am not picking on anybody, but where did this idea come from? I never worked on an '03, the reputation being so bad I refused to. The description of failure sounds like improper heat treating of chrome moly or nickel steel. Mausers, Russians, Carcanos are all cased with junk under them and you don't hear to many stories about receiver failure with them. I recently had a lively discussion about color casing 99 savage receivers. That would react like the description of failure you are talking about, through and through over hardness. Fortunately, most 99s are low pressure rounds and I never heard about any thing bad happening because of it. Like I said, I don't work on '03s, but I used to heat treat a lot of gun parts and I am curious.

it appears that the barrel split as opposed to the receiver. Is that correct? Is there damage to the receiver as well?

The receiver was not damaged. I found other pictures where the barrel blew on double heat treat receivers.

The metal used in those barrels and receivers was similiar plain low carbon steels. Based on the number of blown barrel pictures at the Springfield Armory site, barrels failure was common.

The receivers are not the only thing made from low grade materials made by primitive process controls.

Last edited:

I keep seeing reference to case hardened "rebar like material" in '03 Springfields.I am not picking on anybody, but where did this idea come from

Receivers and bolts of SA, serial number 1 to 800,000 were made of Material, Class C Steel. The double heat treat receivers, Receivers and bolts of SA, serial number 800,000 to 1,275,767, were also Class C steel.

Look up the composition of Class C steel, find a close equivalent today.

When I looked at data on Matweb, the low carbon steel used in these early receivers is today not used for complicated parts, non heat treated it is used for rebar.

I use the rebar analogy as a pejorative.

Mausers, Russians, Carcanos are all cased with junk under them and you don't hear to many stories about receiver failure with them

Hatcher has a section on low number Springfields in his book "Hatcher's Notebook". Without that record of receiver failures we would be oblivious to the systemic issues associated with low number Springfields.

I never knew there was a problem with firestone tires and Ford Explorers until I saw a database of crashes and deaths. Remember this?: http://en.wikipedia.org/wiki/Firestone_and_Ford_tire_controversy

I am unaware of any single entity collecting Mauser, Nagant, Carcano failures. Does that mean they do not happen?

I will bet there are. It is just that they are not being reported here.

I have this picture. Don't know the story.

Last edited:

Gunplummer

New member

Heat treat process

I still do not have a clue as to how the '03s were heat treated. All the report said was "go ahead and chance it". I just see the term heat treated tossed around, but nobody seems to know what process was used. Some of the photo's show material that looks crystallized. I never heard of "class C" steel and suspect it is some vague term used by the industry such as "plow steel". I still don't think the '03s were case hardened, according to the brittle descriptions I see here. Anything that can be cracked with a hammer must have had a lot of carbon in it before heat treating.

I still do not have a clue as to how the '03s were heat treated. All the report said was "go ahead and chance it". I just see the term heat treated tossed around, but nobody seems to know what process was used. Some of the photo's show material that looks crystallized. I never heard of "class C" steel and suspect it is some vague term used by the industry such as "plow steel". I still don't think the '03s were case hardened, according to the brittle descriptions I see here. Anything that can be cracked with a hammer must have had a lot of carbon in it before heat treating.

It is significant that the USMC issued low numbered Springfield rifles during WWII. There is no known case where one of those rifles blew up using military ammo.

It is a known fact that some Springfield rifles were not properly heat treated. It is also a known fact that some .30 caliber ammo issued during WWII was defective. This defective ammo was made by a little known outfit called National Copper and Brass. The cases are very soft and they sometimes failed.

It is a known fact that some Springfield rifles were not properly heat treated. It is also a known fact that some .30 caliber ammo issued during WWII was defective. This defective ammo was made by a little known outfit called National Copper and Brass. The cases are very soft and they sometimes failed.

mapsjanhere

New member

You'd wonder why they added the third lug on the 98 bolt

Part of engineering it right is making a disaster survivable.

Part of engineering it right is making a disaster survivable.

It is significant that the USMC issued low numbered Springfield rifles during WWII. There is no known case where one of those rifles blew up using military ammo.

It that because single heat treat receivers just stopping failing, or is it because the only data base we have is Hatcher's, which ends in 1929?