You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EAA Windicator problem

- Thread starter Nez

- Start date

g.willikers

New member

It's sounding more and more like it's time for a dis-assembly and look see at the internals.

Anyone familiar with the workings of these?

Just looking at the parts view pictures, it's not the usual S&W clone that most are.

But it could just be some easily identifiable crap floating around inside, that's interfering with proper function.

Anyone familiar with the workings of these?

Just looking at the parts view pictures, it's not the usual S&W clone that most are.

But it could just be some easily identifiable crap floating around inside, that's interfering with proper function.

I think I may have solved the problem. I went shooting again today and I did not clean the gun immediately after shooting. I have been sitting here dry firing it and it felt like it was catching on something almost every trigger pull and jammed on a few occasions so I held it up to a light to check clearance between the front and back of the cylinder. When sitting there is a a visible gap between the cylinder and the forcing cone but when the trigger or hammer is depressed the cylinder seems to ride forward into the forcing cone and catches on it, I guess it is more noticeable now that it is dirty. I feel kind of stupid now because that is what some of you originally suggested, I just didn't notice it because I never looked while actually firing it only while the cylinder wasn't moving. I was wondering if this is normal for the cylinder to ride forward into the forcing cone of if it is supposed to stay the same distance while rotating? Also is there anything I can do to adjust this without filing down the forcing cone?

It is definitely the cylinder gap. To clarify I know that the barrel and cylinder should not "rub" I just don't know if its normal for the cylinder to lunge forward between shots. Also I understand there are 2 ways to fix this. There are some thin washers? I can use within the cylinder or I can file or sand (carefully) the barrel down just a bit. I have very little extra money and I would prefer not to see a gunsmith and do it on my own (famous last words). I was wondering what all of you think I should do. I don't have feeler gauges but I can borrow them from my neighbor however based on a visual inspection there is no room for anything when the cylinder is "rotating" between shots, I would say it is .001 or less.

Have you checked the cylinder end-shake? With the gun unloaded pull the trigger and hold it back; now hold the cylinder and try to move it back and forward. If it moves too much you need: 1) to screw-in the ejector rod (Windicators are famous to have this issue); 2) to add a washer. Take it to a good gunsmith or contact EAA.

What is defined as "too much" shake? It moves a little bit but not much. Its more that it lunges forward and gets stuck between shots, during a shot it has plenty of clearance. Also how would I screw in the ejector rod? I have disassembled it and I can not find threads, everything seems to be fixed and I do not want to break anything. Secondly how would I get these washers? I do not want to have to pay a gunsmith (as I already stated I have limited funding, why do you think I got a windicator in the first place?  ). I just want to know if this is something I am capable of fixing without sending it to EAA (for weeks on end) or paying a gunsmith to install a 10 cent washer. I will call EAA tomorrow and inquire but I want to know what everyone thinks.

). I just want to know if this is something I am capable of fixing without sending it to EAA (for weeks on end) or paying a gunsmith to install a 10 cent washer. I will call EAA tomorrow and inquire but I want to know what everyone thinks.

If the cylinder goes so forward to almost touch the forcing cone, there's too end-shake play. It's possible that even if the cylinder doesn't touch the forcing cone when it goes fully forward, the hand doesn't engage the rotating star correctly and the trigger gets stuck.

I've checked the Windicator exploded diagram and it seems there's no treaded things in the ejector rod assembly: it seems that everything is press fitted and/or hold in place by a pin. For the washers you can try powercustom.com, but I don't think they make anything for the Windicator and their products are not cheap. That's why I still think the better thing is to contact EAA or let a good gunsmith to inspect the revolver.

A question: what happens if you dry fire the revolver with the muzzle pointed down?

I've checked the Windicator exploded diagram and it seems there's no treaded things in the ejector rod assembly: it seems that everything is press fitted and/or hold in place by a pin. For the washers you can try powercustom.com, but I don't think they make anything for the Windicator and their products are not cheap. That's why I still think the better thing is to contact EAA or let a good gunsmith to inspect the revolver.

A question: what happens if you dry fire the revolver with the muzzle pointed down?

Last edited:

I dry fired it in 3 positions vertical, straight down, and at about a 20 degree angle down. Up the gap was visible and there was no rubbing whatsoever. At a 20 degree angle down it was very close to rubbing and the gap was barely visible. Down there was no visible gap and it was definitely rubbing but since I cleaned it after last using it it was not catching or getting stuck. The problem seems to be inconsistent, sometimes it works for almost 50-100 rounds without any apparent rubbing or jamming. Other times it starts to jam after just 15-20 rounds (even after being cleaned). There is definitely a correlation between how much gunk is built up on the front end but other than that I can find nothing else. I was going to call EAA but their customer service line is only open until 3 so I will have to wait till tomorrow.

g.willikers

New member

Thin spacer washers and shims can be made from wire.

Steel safety wire works well.

Wrap some around the part to be shimmed, in a coil configuration, remove the wrapped, coiled wire and hammer flat.

Make the coiled wire as thick, with as many coils as necessary for the job.

Crude but effective.

Come to think, a short piece of coil spring should work, too.

Steel safety wire works well.

Wrap some around the part to be shimmed, in a coil configuration, remove the wrapped, coiled wire and hammer flat.

Make the coiled wire as thick, with as many coils as necessary for the job.

Crude but effective.

Come to think, a short piece of coil spring should work, too.

Thanks willikers. I have tried a variety of things including wires and springs and sanding down washers but so far I have failed miserably. There are only two spaces that I could possible put one and only one is really viable and I just can not get a piece of metal thin enough to fit. The thickness is fine but once I hammer it out it is too wide and it is too fragile to file/sand evenly. I guess I will keep experimenting and seeing if I can make something that fits. I also called EAA and I was on hold for about 15 minutes and when someone finally came on they pretty much diverted all my questions and told me to ship it to them which would cost a decent amount of money, and I would have to pay another 20 dollar return fee.

g.willikers

New member

Just to test, you could use a rubber o-ring.

It won't stand up to heat, but it would allow knowing if that's the problem.

It won't stand up to heat, but it would allow knowing if that's the problem.

I tried a rubber O ring and it pushes the gap back way too far, the measurements are just too precise. Also I borrowed a feeler gauge and the distance between the front of the cylinder and the forcing cone is about .004-.005 (I would say .0045) when the cylinder is pushed back. It is close to .001 when pushed forwards, it may even be 0 because it is making solid contact, the smallest gauge is .0015 and that one would not fit. So there is a minimum .003 of end shake, I assume this is too much? Also would .004 even be normal? I seem to recall hearing that .006 was the optimum distance for best performance in most revolvers.

g.willikers

New member

When the cylinder is pushed back to yield the .0045 clearance with the barrel, what is the clearance at the other end, with rounds in the cylinder?

rabbit hunter

New member

Windicator Cylinder Binding

I had this problem once on another revolver. I found that gunk was building up under the extractor, preventing it from returning fully to the closed position. Open the cylinder. Depress and hold the extractor rod down and spray clean between the cylinder & the under side of the extractor with carburetor cleaner. Just a thought. Hope it helps.

I had this problem once on another revolver. I found that gunk was building up under the extractor, preventing it from returning fully to the closed position. Open the cylinder. Depress and hold the extractor rod down and spray clean between the cylinder & the under side of the extractor with carburetor cleaner. Just a thought. Hope it helps.

With the cylinder pushed back and a shell in it the gap is about .004-.005. Under the extractor star is very clean there is no built up gunk so I know that is not the problem. I don't think it will take standard bearings because it is not internally similar to S&W. So to clarify there is between .000-.001 of clearance (my smallest guage is .0015 and it wont fit, and it looks like the gap is closed) at the front of the cylinder when it is pushed forward and about .0045 when it is pushed back. At the back there is about .007 when it is pushed forward and about .0045 when it is pushed back.

g.willikers

New member

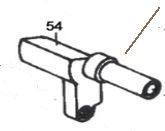

About all I can think of is to use a suitable shim between the shoulder on the crane and the front of the cylinder.

Either that or trim down the boss on the front of the cylinder, where it contacts the shoulder on the crane.

But that's very hard to get right with hand tools.

Either that or trim down the boss on the front of the cylinder, where it contacts the shoulder on the crane.

But that's very hard to get right with hand tools.

Attachments

I really appreciate all the answers and help, thanks 5-shots and willikers. I don't think I am going to do any crane stretching or boss trimming but I may try to put a shim on. If I was able to find a washer or shim that fit on the front are there any metals that are more heat resistant. I know I have some brass, zinc, and steel washers that I may be able to use, I assume steel is the best option for durability and heat resistance?

g.willikers

New member

The shim/washer should be hard enough to resist heat and not flatten or change shape over time.

So steel is the best choice, but at this point whatever fits and works.

While brass will be too soft, bronze might be ok.

Most zink products are zink coated, to prevent rust.

So steel is the best choice, but at this point whatever fits and works.

While brass will be too soft, bronze might be ok.

Most zink products are zink coated, to prevent rust.