Depends.

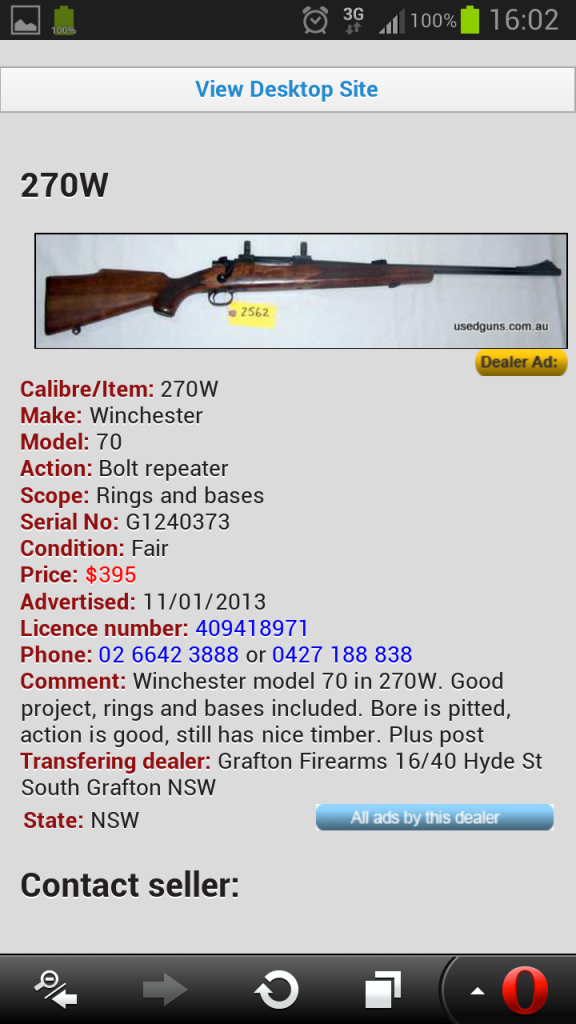

Aftermarket bottom metal can be expensive. For a Model 70, the complete trigger guard, magazine box, bottom metal, etc... could run you another anywhere from $30 to maybe $200 here in the US, depending on the circumstances and configuration.

I have no idea what it would cost in Oz.

Here's what Blackburn bottom metal is currently priced at for various configurations. NB that this isn't a OEM-style bottom metal - this is the type of bottom metal used by high end gun makers here in the US on custom rifles built on top of Model 70 actions. These prices are high because the price of the finished rifles (typically $4K and up) support these levels of parts prices:

http://www.swiftbullets.com/blackburn-gun-metal/pricing-list

Aftermarket bottom metal can be expensive. For a Model 70, the complete trigger guard, magazine box, bottom metal, etc... could run you another anywhere from $30 to maybe $200 here in the US, depending on the circumstances and configuration.

I have no idea what it would cost in Oz.

Here's what Blackburn bottom metal is currently priced at for various configurations. NB that this isn't a OEM-style bottom metal - this is the type of bottom metal used by high end gun makers here in the US on custom rifles built on top of Model 70 actions. These prices are high because the price of the finished rifles (typically $4K and up) support these levels of parts prices:

http://www.swiftbullets.com/blackburn-gun-metal/pricing-list