You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cracks in my brand new Smith and Wesson 986

- Thread starter dale.gribble

- Start date

Master Blaster

New member

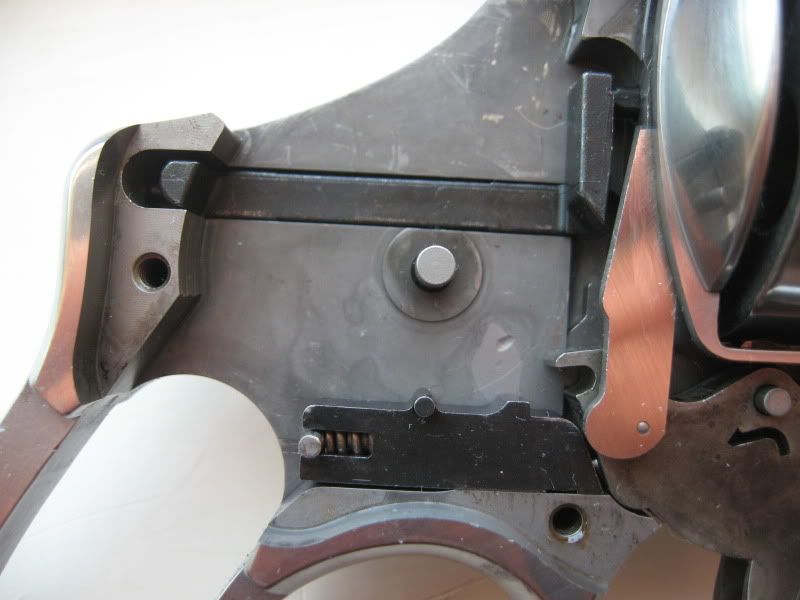

Here is a picture of the inside of the Crane / Frame from my Perfect 1956 K-22

Not the perfect spacing of the Chatter marks where the perfect dull cutting bit was fed to fast. I can show you similar chatter marks on the top strap of a 1967 highway patrolman....

Not the perfect spacing of the Chatter marks where the perfect dull cutting bit was fed to fast. I can show you similar chatter marks on the top strap of a 1967 highway patrolman....

Attachments

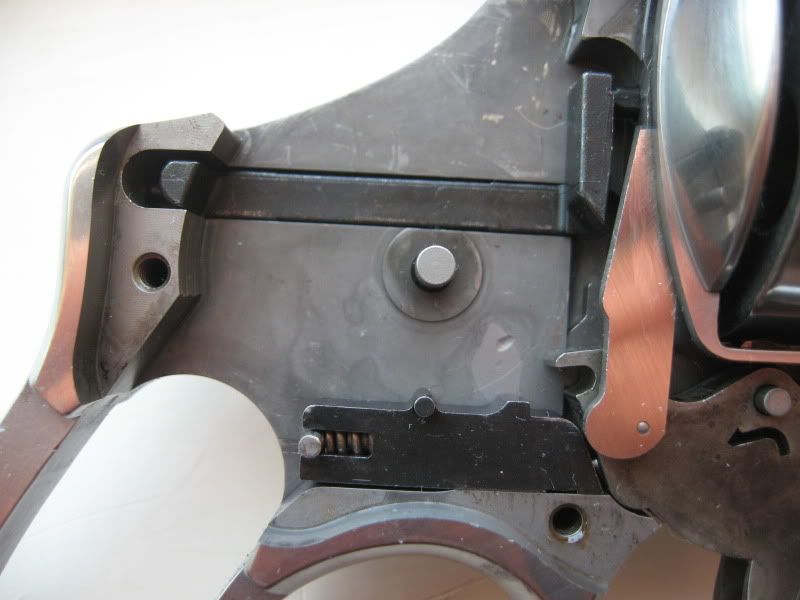

As a point of reference, this picture is the inside of a recent 629 (just barely pre lock). Compare that to the photo of the Registered Magnum I posted. I think, honestly, the machining has improved in the last 80 or so years. So, I may not like the fact that the blue isn't as deep blue as it used to be and, they have switched to production methods that aren't quite the same as they used to be but, honestly, its very good.

I recall in the late 1970's my friends at the Dallas PD gun range got a shipment of brand new S&W 64's in. They told me that half of them were not fit to be issued when they unwrapped them. Timing, carry up issues etc.

They were able to fix about half of that group and get them issued out but, the rest had to returned to Smith and Wesson for major repairs or replacement.

Now, we are not talking about a little cosmetic flaw here and there, we are talking about guns that didn't work.

I recall in the late 1970's my friends at the Dallas PD gun range got a shipment of brand new S&W 64's in. They told me that half of them were not fit to be issued when they unwrapped them. Timing, carry up issues etc.

They were able to fix about half of that group and get them issued out but, the rest had to returned to Smith and Wesson for major repairs or replacement.

Now, we are not talking about a little cosmetic flaw here and there, we are talking about guns that didn't work.

Driftwood Johnson

New member

Yes, the old guns WERE perfect.

Not a scratch, not a scrape, not a ding, not a dent, not a flaw, not a fault anywhere.

A sad world we live in today....

Denis

Oh really? Take a look at the machining inside the frame on this prewar K38. This type of machining was done on pattern following millers, before the existence of CNC machining. Pattern following equipment was operated by hand, with the operator manipulating the cutter path by using a stylus to follow a pattern. Pretty messy looking machining if you ask me.

Of course the surface finish of the floor of the frame does not matter, it is all clearance area. The only thing that really matters is the surface of the studs where the trigger, hammer, and bolt stop rotated. They were a few thousandths above the bottom surface of the frame, so that surface could be as messy as this. However the profile where the side plate fitted had to be just about perfect.

Compare that to the surface finish of this Model 17-3 from 1975. CNC equipment had come into play by this time, so tool paths and feed rates were computer controlled, resulting in a far superior finish. Not that it really mattered, because as with the earlier gun, it is all a clearance cut. Except for the rub mark where the rebound slide slides.

Inside of the frame of a 617-6, from about 2007 if I recall correctly. Notice the raised surfaces of the studs are gone, replaced by raised surfaces on the frame floor for the parts to rotate against. Bottom line, it is cheaper to machine fancy features like that than it is to make studs with a bearing surface and press them in just the right amount.

It is worth noting that the (excellent, as usual) pictures by Driftwood Johnson show not only changes in the milling but also in the studs themselves. The two older guns have machined studs, with three diameters. The newest gun has studs that are simple single diameter pins, inserted to a drive fit into the frame. One more example of making a product less expensive without sacrificing quality and without the customer even knowing there is a difference.

BTW, before removing the sideplate from ANY S&W revolver, always relieve mainspring tension first. One end of the hammer stud is supported by the sideplate and if full mainspring tension is kept when the sideplate is removed, the stud can break. It is a very, very rare occurrence, but a broken stud may mean returning the gun to the factory; most local gunsmiths won't tackle the job.

Jim

BTW, before removing the sideplate from ANY S&W revolver, always relieve mainspring tension first. One end of the hammer stud is supported by the sideplate and if full mainspring tension is kept when the sideplate is removed, the stud can break. It is a very, very rare occurrence, but a broken stud may mean returning the gun to the factory; most local gunsmiths won't tackle the job.

Jim

Cosmodragoon

New member

These same "quality issues"will continue,unless/until customers demand better.But be prepared to pay for it!

I'm just one guy but on something that costs upwards of a grand, I'd be glad to pay an extra $50 to "make it nice", or at least to "make it right"...

bbqncigars

New member

For those with the $, there's the Korth. Very nice, but a little too spendy for most of them. Although that 9mm Sky Marshal is interesting.