stagpanther

New member

I bought a Patriot a few years ago when the they first came out with one in 375 ruger and laminated stock, I thought it would be kinda cool to have a cartridge that theoretically take down anything on the planet, and I simply didn't have a .375 caliber rifle.

I thought it was a steal at its price, I think I paid around $400 and some odd dollars at the time and it seems to function very well.

And then I took it apart and examined it closely, and it looks to me like Mossberg skimped wherever they could. Cheapness in production abounds--but the biggest (and almost inexcusable) shortcut they took IMO was the polymer plastic magazine housing--upon which the action also rests on and the receiver screws are torqued through. This arrangement would strike me as pretty cheesy on a 22 lr--but for a serious recoiling cartridge like the .375 ruger all I can say is "what were you guys thinking?" It's a piece of design junk which will seriously limit the accurate life of the rifle IMO. Making matters even worse, the stock trigger guard is also plastic, so as you torque the main receiver screw both the trigger guard and "magazine bed" compress, and the screw will potentially bind the bolt.

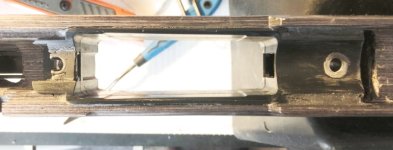

I couldn't find a metal substitute for the magazine housing, so I decided to back it up with devcon and put steel pillars in for the receiver screws. The trigger group is what it is, the triggerpull screw does nothing at all and I'm stuck at 3 lbs--even with the spring removed altogether. I couldn't find a metal trigger guard, so I modified a savage axis metal one to fit and I think it will work OK. The receiver screw holes in the stock were drilled a bit out of alignment originally, so the action was torqued sideways a bit, but I got that fixed when drilling holes for the pillars.

My favorite part about the rifle are the sights (which are apparently Williams), the one place Mossberg really hit the mark, for irons they are excellent IMO. To finish "pimping" the rifle I repainted the chequering to look like something else than cat vomit.

I thought it was a steal at its price, I think I paid around $400 and some odd dollars at the time and it seems to function very well.

And then I took it apart and examined it closely, and it looks to me like Mossberg skimped wherever they could. Cheapness in production abounds--but the biggest (and almost inexcusable) shortcut they took IMO was the polymer plastic magazine housing--upon which the action also rests on and the receiver screws are torqued through. This arrangement would strike me as pretty cheesy on a 22 lr--but for a serious recoiling cartridge like the .375 ruger all I can say is "what were you guys thinking?" It's a piece of design junk which will seriously limit the accurate life of the rifle IMO. Making matters even worse, the stock trigger guard is also plastic, so as you torque the main receiver screw both the trigger guard and "magazine bed" compress, and the screw will potentially bind the bolt.

I couldn't find a metal substitute for the magazine housing, so I decided to back it up with devcon and put steel pillars in for the receiver screws. The trigger group is what it is, the triggerpull screw does nothing at all and I'm stuck at 3 lbs--even with the spring removed altogether. I couldn't find a metal trigger guard, so I modified a savage axis metal one to fit and I think it will work OK. The receiver screw holes in the stock were drilled a bit out of alignment originally, so the action was torqued sideways a bit, but I got that fixed when drilling holes for the pillars.

My favorite part about the rifle are the sights (which are apparently Williams), the one place Mossberg really hit the mark, for irons they are excellent IMO. To finish "pimping" the rifle I repainted the chequering to look like something else than cat vomit.

Attachments

Last edited: