You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Colt arbor and wedge?

- Thread starter olmontanaboy

- Start date

51_60_colt

New member

no, I didnt think that it was the arbor that was damaged, i was thinkin the arbor pulled loose from the frame...its hard to describe things in writting somtimes

madcratebuilder

New member

A loose arbor well more than likely damage the frame, like mykeal said. That well require an oversize arbor to repair.

All this soft brass talk was some thinking brass is really soft, it is not. In fact, some brass alloys can be harder than some steel alloys.

If your brass gun is in good condition and you keep the loads reasonable it well give you similar service as a steel frame gun shooting heavier loads.

All this soft brass talk was some thinking brass is really soft, it is not. In fact, some brass alloys can be harder than some steel alloys.

If your brass gun is in good condition and you keep the loads reasonable it well give you similar service as a steel frame gun shooting heavier loads.

suift,

What are your photos showing? Are you saying that the arbors are being indented by the top of the arbor hole?

That could as well be gas cutting from the blast of hot gases from firing. Colt did not have a provision to prevent gas cutting of the arbor until the '71-'72 Opentop cartridge model, an extension of the cylinder's center.

Threads on the Uberti Colt's arbors is 5/16-18, about 50 Rockwell, a decent size "bolt". Colt itself used 3/8-20.

A new arbor can be made, but it would take some skill and machinery. Also available from VTI for 20 bucks.

If the frame has the threads pulled out or stretched, 5/16-18 is a common thread. It might be possible to Heli-Coil the frame.

As to welded in arbors on steel frames, they have been known to crack the weld, loosen. Nothing is fool proof. When they DO make something fool proof, we'll just grow some smarter fools.

Cheers,

George

What are your photos showing? Are you saying that the arbors are being indented by the top of the arbor hole?

That could as well be gas cutting from the blast of hot gases from firing. Colt did not have a provision to prevent gas cutting of the arbor until the '71-'72 Opentop cartridge model, an extension of the cylinder's center.

Threads on the Uberti Colt's arbors is 5/16-18, about 50 Rockwell, a decent size "bolt". Colt itself used 3/8-20.

A new arbor can be made, but it would take some skill and machinery. Also available from VTI for 20 bucks.

If the frame has the threads pulled out or stretched, 5/16-18 is a common thread. It might be possible to Heli-Coil the frame.

As to welded in arbors on steel frames, they have been known to crack the weld, loosen. Nothing is fool proof. When they DO make something fool proof, we'll just grow some smarter fools.

Cheers,

George

olmontanaboy

New member

Amen brother.When they DO make something fool proof, we'll just grow some smarter fools.

I have an older Pietta 1860 Army - a late-1980's manufacturing code. Hadn't shot it for years until about a month ago, when I became interested in cap & ball revolvers again. I read about "short arbor syndrome" and tested my Pietta, and sure enough it WAS too short.

My solution was to find a couple of thin washers - actually washers for 1/8" pop-rivets were just about perfect in diameter. I ended up stoning the two washers to get them to just the right thickness (one by itself was too thin, but two together were too thick), then used blue Loc-Tite to "glue" 'em into the bottom of the arbor hole in the barrel.

Fit is perfect now.

Maybe today Pietta fits the arbor correctly, but not back when my old revolver was made.

I understand that the deal was that, back in the day when Colt was making these revolvers, they made all of their arbors too long, and during the barrel fitting process the gunsmith would file the end off of the arbor and keep test fitting and filing until he got it perfect - you can always cut more off, but you can't ever cut more on, so to speak. Pietta (and Uberti) made all of their arbors purposely too short so that any barrel could mate with any arbor/frame.

I understand that Pietta invested in some new, modern CNC machining centers fairly recently. That's probably why the new Piettas have a reputation for their arbors being right - their manufacturing tolerances are so much better with the new machinery.

My solution was to find a couple of thin washers - actually washers for 1/8" pop-rivets were just about perfect in diameter. I ended up stoning the two washers to get them to just the right thickness (one by itself was too thin, but two together were too thick), then used blue Loc-Tite to "glue" 'em into the bottom of the arbor hole in the barrel.

Fit is perfect now.

Maybe today Pietta fits the arbor correctly, but not back when my old revolver was made.

I understand that the deal was that, back in the day when Colt was making these revolvers, they made all of their arbors too long, and during the barrel fitting process the gunsmith would file the end off of the arbor and keep test fitting and filing until he got it perfect - you can always cut more off, but you can't ever cut more on, so to speak. Pietta (and Uberti) made all of their arbors purposely too short so that any barrel could mate with any arbor/frame.

I understand that Pietta invested in some new, modern CNC machining centers fairly recently. That's probably why the new Piettas have a reputation for their arbors being right - their manufacturing tolerances are so much better with the new machinery.

My solution was to find a couple of thin washers - actually washers for 1/8" pop-rivets were just about perfect in diameter. I ended up stoning the two washers to get them to just the right thickness (one by itself was too thin, but two together were too thick), then used blue Loc-Tite to "glue" 'em into the bottom of the arbor hole in the barrel.

That's interesting; traditional Loc-Tite wouldn't have been my first choice since it's not really primarily an adhesive.

Having said that, I've done a similar thing. Of my seven Ubertis, only two had arbor-to-barrel fit issues (and they are both 1851 variants, go figure).

I used a shim washer and an internally-toothed lock washer, which I flattened gradually in a vise until it was the proper thickness...then I JB-Welded them to the end of the arbor. So far, so good. And the wedges fit a lot better now.

madcratebuilder

New member

AdmiralB said:That's interesting; traditional Loc-Tite wouldn't have been my first choice since it's not really primarily an adhesive.

Actually it is a high temp adhesive available in different strengths, just not marketed as that. If you need a gap filling adhesive you can use the loc-tite 'stud and bearing mount' Several years ago I attended a two day seminar put on by loc-tite about product application.

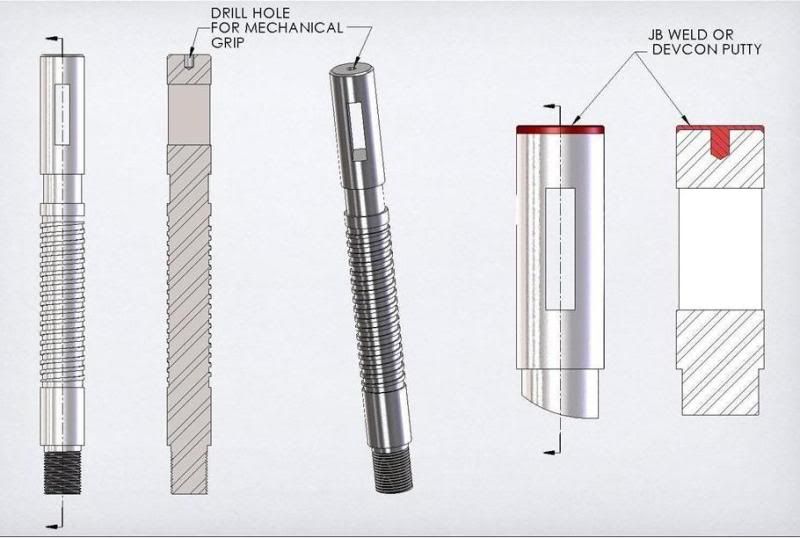

Here's a method of using JB on the end of the arbor. I think Devcon would be a better choice for this as it is stronger that JB in my experience. This diagram was copied from another forum, I think it originated with articap. I want to try this once and see how well it holds up in actual uses. It may be a good method if you are working with a very thin layer.

This diagram was copied from another forum, I think it originated with articap.

I've never seen that diagram before in my life!

Last edited:

madcratebuilder

New member

Noz said:DEVCON vs JB Weld.

Tried using Devcon to replace JB in the hammers of Colt style revolvers. No comparison. Devcon did not last a single firing. JB will go several shoots.

That's strange. I've been using Devcon for thirty years. Repaired cast iron engine blocks and cylinder heads. I have machined it on mills, turned it on lathes and tapped it for threaded fasteners. Always has worked well for me with in it's limitations. Devcon comes in several formulas, steel, titanium, aluminum, stainless steel to name a few. Maybe you used the small tube stuff, that's it's not the good Devcon, it shears at 1600psi, the good stuff shears at 3200psi. It does have it's limitations, heat over 350* or so kills it, adheres much better to a textured surface vs a smooth surface.