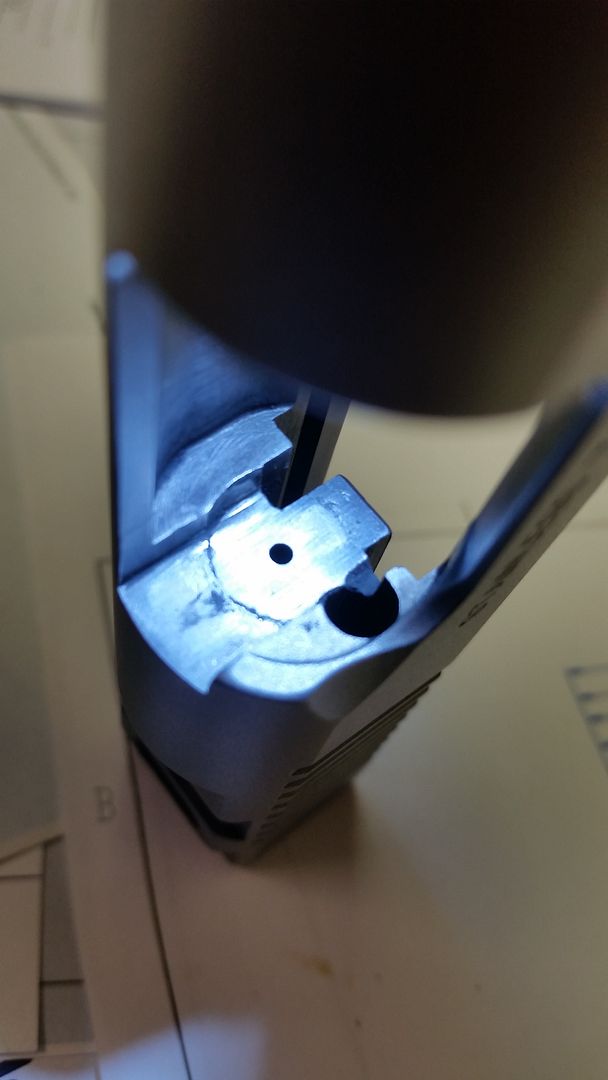

A while back I shot some old aluminum cased ammo that got wet. I know it was dumb. Anyway several cases came apart and I trashed the remainder of the cartridges. I have since noticed a ring where my cartridges seat on my slide and I did a chamber inspection and found the below pics. Its a little hard to see in the pics but there is material missing up to about .007" deep all around the entrance area of the chamber. I am waiting on a new barrel now. But did the bad ammo do this? Could it have been a bad chamber from the get go? It doesnt look like reamer runout to me.