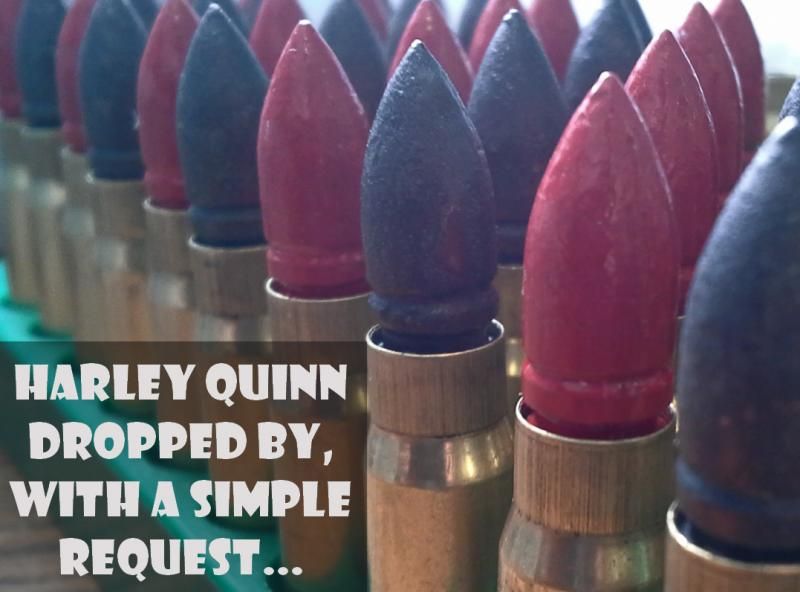

I've been shooting some cast bullets out of my 257 Roberts AI recently. They aren't as consistent as jacketed bullets, but they shoot pretty tight for the most part with the right load. I am doing 2000fps with straight clip-on wheel weights dropped into water.

I've had a couple groups inside a minute. Cheap shooting, low recoil, and very little wear and tear on the rifle. What's not to like?

I've had a couple groups inside a minute. Cheap shooting, low recoil, and very little wear and tear on the rifle. What's not to like?