I tried a sample of 200 gr .311 cast bullets from Eggleston Munitions for my 91/30 MN. I used 35 gr of Reloader 15 and of Varget powder instead of the standard 42.5 gr load. The results for both powders were disappointing with the bullet going five feet in any direction at 100 yards. I've had great success with Hornady 150 gr SP with 35 gr Varget. What do you think is going on (other than blaming the shooter of course)? TIA

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cast bullets

- Thread starter rklapp

- Start date

Modern cast lead rifle bullet shooters have gone to "bore riding" bullets. The fore part of the bullet must fit into the bore with slight thumb pressure. If the fore part of the bullet has too much play, the bullet will produce the lack of accuracy that you describe. You may want to visit the "Cast Lead Bullet Association's" web site. They have been conducting matches with cast lead bullets for years.

http://www.castbulletassoc.org/

http://www.castbulletassoc.org/

I second Da Hermit's comments. I will also add the if your bullet is a bore riding style, stick one into the muzzle. It should be a snug fit with no wiggle space. If the nose is slightly engraved by the rifling, so much the better.

You might also slug your bore to find the true groove diameter. I don't shoot Moisin's so I'm not sure but I think they run around .312". If so the bullet should be sized to .314" or .002" larger than groove diameter. If your current bullets are .311" and your bore .312", then that bullet will literally bounce from side to side and probably lead like hell, figuratively speaking.

Paul B.

You might also slug your bore to find the true groove diameter. I don't shoot Moisin's so I'm not sure but I think they run around .312". If so the bullet should be sized to .314" or .002" larger than groove diameter. If your current bullets are .311" and your bore .312", then that bullet will literally bounce from side to side and probably lead like hell, figuratively speaking.

Paul B.

Cast bullets are an entirely different game. Powders that work well aren't necessarily going to be the same, and the variability you get from one charge to the next are going to be a lot greater.

And to parrot the poster above, you need to slug the bore to find out what size bullet you need.

And to parrot the poster above, you need to slug the bore to find out what size bullet you need.

Cast bullets don't do well with full power powder charges.

If you have Unique, Red Dot, or 2400 on hand you can work up some mild loads with good accuracy. If you have H4895 you can probably work up to 34 grains or so with good accuracy.

What you can't do is shoot them fast, the Mosin Nagant has a relatively tight twist, around 1:9.4 inches, this means that your bullets can actually deform from being shot too fast (which spins them too fast). 1,800 fps is generally the upper limit for Mosins and Mausers with normal lead bullet techniques.

Secondly, full power jacketed bullet loads smack the heck out of a cast bullet, so it gets jammed hard and easily deformed going into the barrel. Odds are you have some significant leading in your bore based on the loads you shot.

Now there are exceptions to this, but that's a bit more advanced than "buy bullet, load bullet, shoot bullet."

Jimro

If you have Unique, Red Dot, or 2400 on hand you can work up some mild loads with good accuracy. If you have H4895 you can probably work up to 34 grains or so with good accuracy.

What you can't do is shoot them fast, the Mosin Nagant has a relatively tight twist, around 1:9.4 inches, this means that your bullets can actually deform from being shot too fast (which spins them too fast). 1,800 fps is generally the upper limit for Mosins and Mausers with normal lead bullet techniques.

Secondly, full power jacketed bullet loads smack the heck out of a cast bullet, so it gets jammed hard and easily deformed going into the barrel. Odds are you have some significant leading in your bore based on the loads you shot.

Now there are exceptions to this, but that's a bit more advanced than "buy bullet, load bullet, shoot bullet."

Jimro

When I was a member of the Cast Lead Bullet Association they were conduction matches where the shooters had to publish their loads. If you are serious about accuracy in rifles using cast lead bullets you should join and access their match results to see what bullets, powders and loads the current winners (I stopped doing lead rifle loads some years ago), are using. When I was shooting cast in rifles (I got old), they were keeping the velocity to about the speed of sound (1100 fps). Many of the winners back then were using Rx 7. My load in a Ruger #1 in 30-06 was a bore-riding Saeco 301, with 24.0 grains of Rx 7, which gave me just under an inch a 100 yards for five shot groups. However, that was then, this is now...it would behove you to see what the winners are using nowadays.The bore is 312. Should I try a lighter load like 30 gr and work my way up? That's 12.5 gr less than standard.

It was notable that Rx7 shot well in all my cast bullet rifles except one.

By the way, members of the Cast Lead Bullet Association would get the "Fouling Shot", magazine where the match results printed...it was a great source for those interested in casting for rifles.

You're skating .311" lead down a .312" groove diameter barrel...You won't be able to hit where you are aiming...

Try the fattest bullet that will chamber once seated in a case...

With a 312" groove, I would be starting with a .314" diameter bullet, and then I would use a gas-checked bullet if I was trying for a near full power load...

I am a big fan of cast and mid range (<1,800fps) rifle loads...

Try the fattest bullet that will chamber once seated in a case...

With a 312" groove, I would be starting with a .314" diameter bullet, and then I would use a gas-checked bullet if I was trying for a near full power load...

I am a big fan of cast and mid range (<1,800fps) rifle loads...

I appreciate the feedback. I don't believe there's a difference with a .311 in a .312 bore but there is with a .308 in a .312.

https://www.youtube.com/watch?v=GlkKE7FO7G8

https://www.youtube.com/watch?v=ktfC2fUu_E4

Granted, these weren't with cast bullets.

https://www.youtube.com/watch?v=GlkKE7FO7G8

https://www.youtube.com/watch?v=ktfC2fUu_E4

Granted, these weren't with cast bullets.

Last edited:

Cast and jacketed are entirely different animals...

Jacket material can grab rifling much more effectively than bare lead...

Undersized lead tends to 'jump' the rifling, or skate across the lands instead of spinning...

I use .357" jacketed pistol bullets in my .35 Remington just fine, but need .360" cast to get acceptable accuracy, and no leading...

Groove is .358"...

Jacket material can grab rifling much more effectively than bare lead...

Undersized lead tends to 'jump' the rifling, or skate across the lands instead of spinning...

I use .357" jacketed pistol bullets in my .35 Remington just fine, but need .360" cast to get acceptable accuracy, and no leading...

Groove is .358"...

"I appreciate the feedback. I don't believe there's a difference with a .311 in a .312 bore but there is with a .308 in a .312."

Au contraire mon ami. Salmoneye described it very well what will happen.

I started hand loading back in 1954 using bullets I cast myself. Fortunately I was blessed by an old gentleman who was my mentor and it was several years before I even loaded a jacketed bullet.

Up until my wife had a stroke, I was shooting several times a week, working up hunting loads for some rifles and shooting cast bullets the rest of the time with the rest. There have been time when I shout 50 to 100 cast bullets for every jacketed bullet.

You shoot .311 cast bullets in a .312" bore (actually groove diameter) and the hours you spend "getting the lead out" will make you a believer. Not my idea of fun.

Another thing, due to slower barrel time, follow though is much more important with cast, even from the bench and more so from normal field positions.

Frankly, shooting cast bullets with accuracy is a whole "nuther" ball game. Loading for jacketed ammo is grammar, middle and high school stuff. Getting serious with cast is college/university level hand loading if you're really serious about shooting it. I shoot a Winchester M70 Youth Ranger in .308 that I won in a raffle at a gun shot. I can load a 180 gr. cast bullet in that rifle and get 1.5 MOA at 200 yards and .2.5 MOA at 300 yards if it ain't too damn windy. I'm happy at that level and it would not even be competitive at a CBA match. I have a load with the same bullet for a 30-06 that if I hit the top one quarter of a 300 meter pig silhouette, the bullet will usually know it over. I shoot for pleasure, not competition but still want the best accuracy I can get with my off the shelf rifles.

Look for a bullet like the Lyman #311291 for 30 caliber and try and find something similar that's sized to .314". Run about 25.0 gr. of any 4895 with the bullet seated to slightly engage the rifling. You may or may not need a one gr. filler of Dacron or kapok to hold the powder against the primer but I'll bet that will give you a good start on finding a decent load.

Paul B.

Au contraire mon ami. Salmoneye described it very well what will happen.

I started hand loading back in 1954 using bullets I cast myself. Fortunately I was blessed by an old gentleman who was my mentor and it was several years before I even loaded a jacketed bullet.

Up until my wife had a stroke, I was shooting several times a week, working up hunting loads for some rifles and shooting cast bullets the rest of the time with the rest. There have been time when I shout 50 to 100 cast bullets for every jacketed bullet.

You shoot .311 cast bullets in a .312" bore (actually groove diameter) and the hours you spend "getting the lead out" will make you a believer. Not my idea of fun.

Another thing, due to slower barrel time, follow though is much more important with cast, even from the bench and more so from normal field positions.

Frankly, shooting cast bullets with accuracy is a whole "nuther" ball game. Loading for jacketed ammo is grammar, middle and high school stuff. Getting serious with cast is college/university level hand loading if you're really serious about shooting it. I shoot a Winchester M70 Youth Ranger in .308 that I won in a raffle at a gun shot. I can load a 180 gr. cast bullet in that rifle and get 1.5 MOA at 200 yards and .2.5 MOA at 300 yards if it ain't too damn windy. I'm happy at that level and it would not even be competitive at a CBA match. I have a load with the same bullet for a 30-06 that if I hit the top one quarter of a 300 meter pig silhouette, the bullet will usually know it over. I shoot for pleasure, not competition but still want the best accuracy I can get with my off the shelf rifles.

Look for a bullet like the Lyman #311291 for 30 caliber and try and find something similar that's sized to .314". Run about 25.0 gr. of any 4895 with the bullet seated to slightly engage the rifling. You may or may not need a one gr. filler of Dacron or kapok to hold the powder against the primer but I'll bet that will give you a good start on finding a decent load.

Paul B.

If the GROOVE diameter is really 0.311" all along the length of the barrel, you should be shooting 0.313" lead bullets. If you are going to be shooting over 1800 fps, you should be shooting with gas checks.

IF you have not slugged the barrel, you are truly "shooting blind."

Read:

http://7.62x54r.net/MosinID/MosinSlug.htm

The main complaint I have is the following:

"A bullet larger than the groove diameter can cause dangerously high pressure when the rifle is fired"

This is all taken care of when doing load work-up from the start load, provided we are only talking about 3 mils max. At the very least, it should read "A Jacketed bullet..."

If you are foolish enough to switch bullet diameter without load work-up or if you are foolish enough to switch COL without load work-up or if you switch lot numbers of powder without load work-up, does not make these things dangerous in themselves, but rather it is the technique that failed.

IF you have not slugged the barrel, you are truly "shooting blind."

Read:

http://7.62x54r.net/MosinID/MosinSlug.htm

The main complaint I have is the following:

"A bullet larger than the groove diameter can cause dangerously high pressure when the rifle is fired"

This is all taken care of when doing load work-up from the start load, provided we are only talking about 3 mils max. At the very least, it should read "A Jacketed bullet..."

If you are foolish enough to switch bullet diameter without load work-up or if you are foolish enough to switch COL without load work-up or if you switch lot numbers of powder without load work-up, does not make these things dangerous in themselves, but rather it is the technique that failed.

rklapp,just to reinforce what other have said,that bullet is not going to shoot accurately in your Mosin no matter what powder or charge weight you use.

That particular bullet even if gas checked simply doesn't have enough dia. to engage the rifling properly in a .312" groove bore,which can cause gas blowby around the bullet which affects both velocity as well as accuracy. If that bullet were not coated it would have leaded your bore pretty badly within a few shots as the blowby would have burned the lube right off and left you shooting naked lead down the bore.

Undersized bullets also cause instability problems I'm surprised you weren't getting keyholes on your target but you can tell the bullet became unstable due to the large groups you were getting.

The plain base style bullet doesn't help much either although if it were of the proper dia. you could get some usable velocity and accuracy out of it but not jacketed bullet type velocity. With the Mosin's 1:10 twist bore and that bullet weight / length if it were of the proper dia. an gas checked your probably looking at about 1900+ fps. tops before you over spin the bullets as the bullets imperfection become more accentuated after you pass a certain velocity / RPM threshold with a given twist bore. The only way to increase that same cast bullets velocity and retain accuracy within the bullets usable RPM range is to use a slower twist barrel like a 1:12 or 1:14 but we have to use what we have.

In rifles when using the fast to med. fast burning powders that don't require a filler and ignite easily with reduced charges that give quick acceleration of the cast bullet,usable velocity / accuracy is going to be lower. Think of how the bullet is pushed into the leads on the one hand you pull up to a cars bumper and give it a gentle push to get it moving no damage is done to the bumper of the car being push. On the other hand ram that same cars bumper with yours at high speed and what happens to the cars bumper,the same thing happens to cast bullet along the entire length from the nose to the base,it get jammed,compressed and twisted by the fast acceleration induced by the powder burn. Slow powders like H-4895 give the bullet a slow gentle push an can safely be reduced down to 60% or the original MAX load and worked up to find the best velocity / accuracy with a given cast bullet. In general I've found that the slower powders tend to give better consistent shot to shot performance with a Dacron filler between the powder column and bullets base.

There is a reason you don't see RL#15 or Varget listed for cast bullets loads in cast bullet manuals it's not an appropriate powder for the cartridge / bullet listed. Reducing the charge weight of a given powder below what is listed or just on a whim that it might work is not only dangerous but will usually give you erratic results usually in the form of irregular burn / ignition characteristics which cause pressure spikes,velocity swings and poor accuracy. A chrono would have told you much about the consistency or lack there of,of those loads you were shooting.

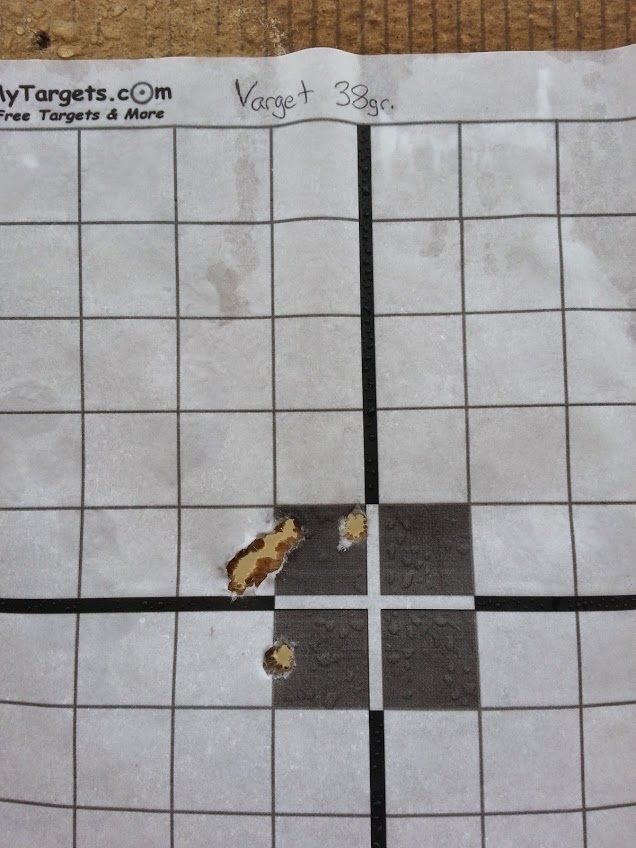

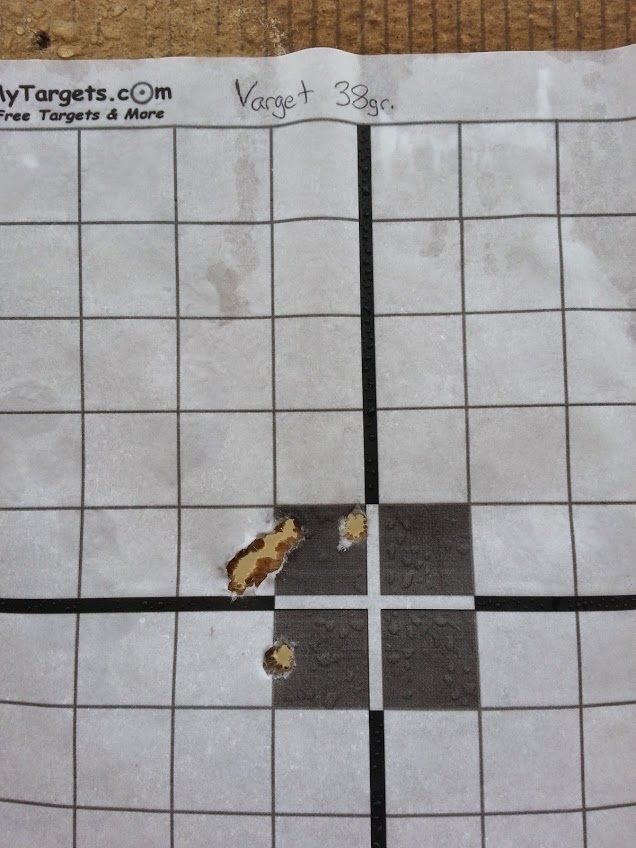

Here are some of the results you can get when the proper powders and bullet combinations when the correct dia. bullet is used. These two loads were fired in my 1933 Tula 91/30 using a Lee .312" 185 gr. gas check bullet cast from clip on wheel weight plus some Tin and water quenched straight from the mold then sized and checked an lubed with Lars 2500+ lube a couple days later. The bullet actually cast right at .314" an are sized and checked as such. My two Mosin rifles have .312" groove bores.

Tomorrow will be day 2 shooting some test loads in my quest to get as close to the 2K velocity / RPM threshold with this particular bullet load combo. I'm up to just over 1700 fps. with 33.0 grs. of H-4895. I also have a good general purpose load using 19.0 grs. of Alliant 2400. But accuracy start to taper off as the charge weight goes up so I stopped where I was with that combo.

Two 5 shot 50 yd. test groups.iron sights.

That particular bullet even if gas checked simply doesn't have enough dia. to engage the rifling properly in a .312" groove bore,which can cause gas blowby around the bullet which affects both velocity as well as accuracy. If that bullet were not coated it would have leaded your bore pretty badly within a few shots as the blowby would have burned the lube right off and left you shooting naked lead down the bore.

Undersized bullets also cause instability problems I'm surprised you weren't getting keyholes on your target but you can tell the bullet became unstable due to the large groups you were getting.

The plain base style bullet doesn't help much either although if it were of the proper dia. you could get some usable velocity and accuracy out of it but not jacketed bullet type velocity. With the Mosin's 1:10 twist bore and that bullet weight / length if it were of the proper dia. an gas checked your probably looking at about 1900+ fps. tops before you over spin the bullets as the bullets imperfection become more accentuated after you pass a certain velocity / RPM threshold with a given twist bore. The only way to increase that same cast bullets velocity and retain accuracy within the bullets usable RPM range is to use a slower twist barrel like a 1:12 or 1:14 but we have to use what we have.

In rifles when using the fast to med. fast burning powders that don't require a filler and ignite easily with reduced charges that give quick acceleration of the cast bullet,usable velocity / accuracy is going to be lower. Think of how the bullet is pushed into the leads on the one hand you pull up to a cars bumper and give it a gentle push to get it moving no damage is done to the bumper of the car being push. On the other hand ram that same cars bumper with yours at high speed and what happens to the cars bumper,the same thing happens to cast bullet along the entire length from the nose to the base,it get jammed,compressed and twisted by the fast acceleration induced by the powder burn. Slow powders like H-4895 give the bullet a slow gentle push an can safely be reduced down to 60% or the original MAX load and worked up to find the best velocity / accuracy with a given cast bullet. In general I've found that the slower powders tend to give better consistent shot to shot performance with a Dacron filler between the powder column and bullets base.

There is a reason you don't see RL#15 or Varget listed for cast bullets loads in cast bullet manuals it's not an appropriate powder for the cartridge / bullet listed. Reducing the charge weight of a given powder below what is listed or just on a whim that it might work is not only dangerous but will usually give you erratic results usually in the form of irregular burn / ignition characteristics which cause pressure spikes,velocity swings and poor accuracy. A chrono would have told you much about the consistency or lack there of,of those loads you were shooting.

Here are some of the results you can get when the proper powders and bullet combinations when the correct dia. bullet is used. These two loads were fired in my 1933 Tula 91/30 using a Lee .312" 185 gr. gas check bullet cast from clip on wheel weight plus some Tin and water quenched straight from the mold then sized and checked an lubed with Lars 2500+ lube a couple days later. The bullet actually cast right at .314" an are sized and checked as such. My two Mosin rifles have .312" groove bores.

Tomorrow will be day 2 shooting some test loads in my quest to get as close to the 2K velocity / RPM threshold with this particular bullet load combo. I'm up to just over 1700 fps. with 33.0 grs. of H-4895. I also have a good general purpose load using 19.0 grs. of Alliant 2400. But accuracy start to taper off as the charge weight goes up so I stopped where I was with that combo.

Two 5 shot 50 yd. test groups.iron sights.

Last edited:

weaselfire

New member

Five feet at 100 yards? Isn't that normal for Mosins?

Most cast lead in Mosin barrels doesn't do well. The other suggestions are right on.

Jeff

Sent from my XT1254 using Tapatalk

Most cast lead in Mosin barrels doesn't do well. The other suggestions are right on.

Jeff

Sent from my XT1254 using Tapatalk

"A bullet larger than the groove diameter can cause dangerously high pressure when the rifle is fired"

I think there is a word missing from that statement. The word is "significantly".

A bullet significantly larger than groove diameter, is a problem. And by significant, I mean something like shooting a .30 bullet through a .270 bore.

Cast bullets are supposed to be "oversize" compared to the groove diameter. 0.002" is the usual standard, but not a hard and fast rule, as different rifles prefer different things.

One thing nearly all don't like is undersize bullets.

.311" in a .312" is definitely undersized.

I bought a sample pack from Eggleston for 15 cents per round. The owner showed me his results.

Originally, I seated them far in to about 2.80" OAL (with aweful results).

I have my new test rounds ready. I backed the bullet out to 3.06" OAL with loads of 40, 30, 25, and 20 gr Reloader 15. If these don't work, then I'm going back to jacketed bullets. (Note: I'm also comparing my new Norma brass to my old WIN brass.)

Originally, I seated them far in to about 2.80" OAL (with aweful results).

I have my new test rounds ready. I backed the bullet out to 3.06" OAL with loads of 40, 30, 25, and 20 gr Reloader 15. If these don't work, then I'm going back to jacketed bullets. (Note: I'm also comparing my new Norma brass to my old WIN brass.)