Not sure where to start. Looking to build up some full powder 44 mags for a 44mag henry lever gun. Casting my own using a lee 240g swc gas checked mold. bullets are around 13bhn as cast. was considering water dropping. bullets will be powder coated so I was not sure if water drop was needed. will be gas checked.

Goal is a full power 44 mag load.

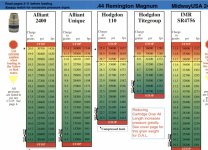

I have been using h110 with my 240g jacketed bullets, but am finding little load data for h110 with lead bullets.

currently have

h110 (trouble finding load data)

power pistol (AA only lists up to 210g bullets in 44mag)

hp-38

cfe-pistol

AA #7

clays (too fast)

I checked several sources so far from Hodgdon for pistol with a 240g swc had the best data.

CFE Pistol start 9.9 at 1117, max 11.9 at 1299

HP-38 start 5.5 at 800, max 11.0 at 1344

#7 start 14.7 at 1180, max 6.3 at 1341

with PC/gas checked, will I be able to use jacketed data, presuming the base is seated similarly?

Goal is a full power 44 mag load.

I have been using h110 with my 240g jacketed bullets, but am finding little load data for h110 with lead bullets.

currently have

h110 (trouble finding load data)

power pistol (AA only lists up to 210g bullets in 44mag)

hp-38

cfe-pistol

AA #7

clays (too fast)

I checked several sources so far from Hodgdon for pistol with a 240g swc had the best data.

CFE Pistol start 9.9 at 1117, max 11.9 at 1299

HP-38 start 5.5 at 800, max 11.0 at 1344

#7 start 14.7 at 1180, max 6.3 at 1341

with PC/gas checked, will I be able to use jacketed data, presuming the base is seated similarly?