Don Fischer

New member

Did you ever figure out what it is?

Sounds like a Don Meredith thing; "If ifs and buts were gifts and nuts we all would have a Merry Christmas.

F. Guffey.

Mr. Guffy (and others) are correct, a properly sized brass for YOUR chamber will stop a bunch of issues & problems.

Mississippi has previously written about fitting his brass to his chamber, and he's shooting really accurately...

What I read was this was a totally unexpected fluke and was wondering if it was an anomaly or some issue that just cropped up...

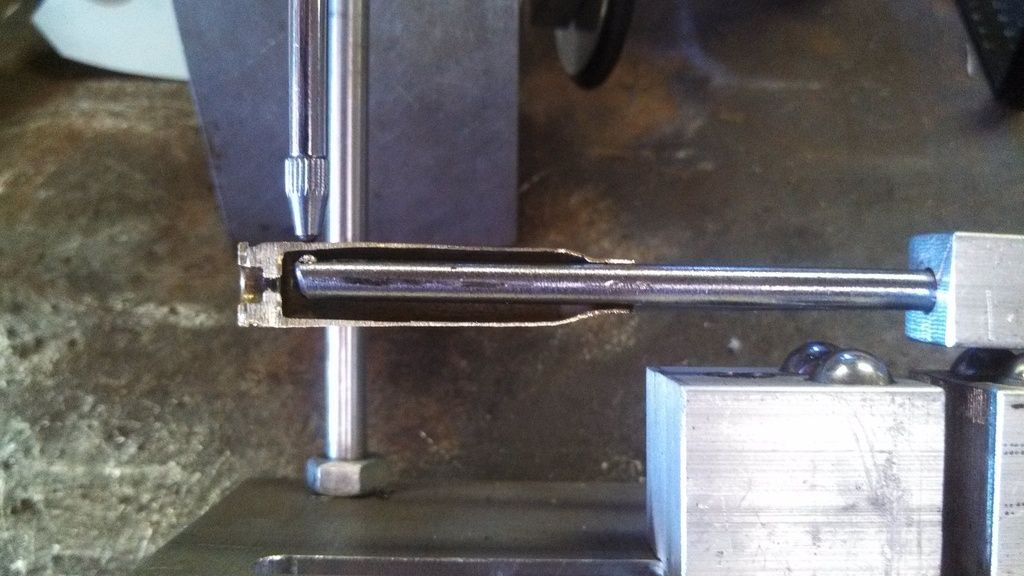

But I am wondering what happened. This was 2x fired lake city, shooting a 175 grain smk with 41 gr IMR 4064 at about 2400 fps out of my AR 10.

Again, I purchase cases that will not chamber in one of my rifles because manufacturers do not sell cases for long chambers. When I purchases once fired cases I purchase the cases with the original primer, if the primer has been removed I do not assume it is a once fired case. But, if the case has been fired once the case head expansion shoulder be .00025", if the case has been hammered and or fired more than once the case head should be larger in diameter than a factory once fired case.

Found my shop notes, it's called "Dislocation Density".

The brass was purchased as once fired from sportsman's guide. I suppose some of it could have been fired from an unsupported machine gun chamber.

Support doesn't have anything to do with a case stretching, length wise. It would be pretty easy to tell if the gun it had been fired from had excessive head space because after sizing you would have had a lot more than normal amount of trimming needed.

Support does matter. Because if it fires slightly out of time/battery the case can bulge at the rear near the head.

Support does matter. Because if it fires slightly out of time/battery the case can bulge at the rear near the head.