That was baaaaad!

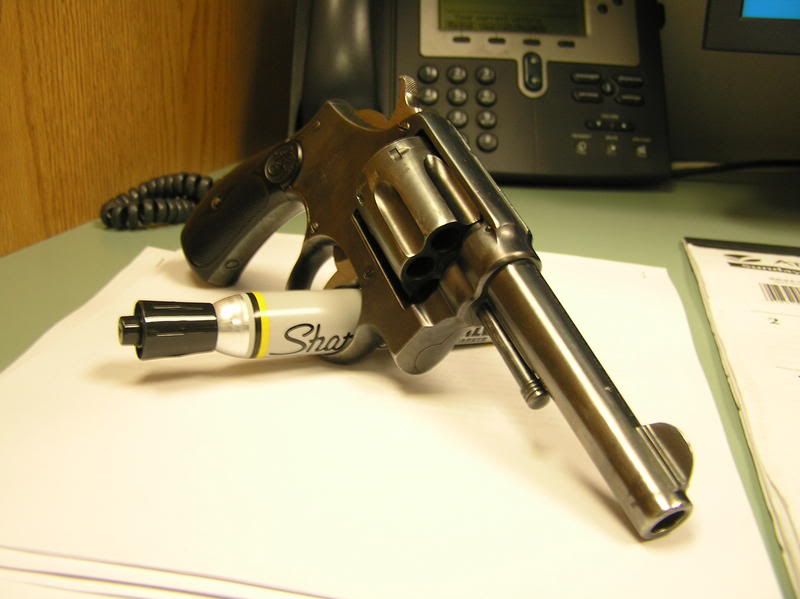

Some of the folks might have noted my post on the Ladysmith I acquired. At the time I did the pictures, I thought I had misplaced the upper side plate screw, but it turned out it had been missing before I bought the gun.

I found out that (believe it or not) the upper sideplate screw for a pre-Model 10 will fit the Ladysmith. Those screws are like gold these days, but I did get one and only had to shorten it a bit because the Ladysmith frame is thinner. I couldn't get a nickel plated one, so I took off the blue and it looks, not really OK, but not too bad.

Looking at the lockwork of the Model 1899, it is amazing that S&W has managed to make such a large number of improvements without (up to the "lock") changing their basic frame outline and shape. The aim has always been to improve and simplify the lockwork, while keeping costs down. (Some would say "making it cheaper" but what is really wrong with that?) I can't see that any of those changes made the gun less reliable, less accurate, or less functional. Some folks may get all bothered about using coil springs or MIM parts, but if I can buy a gun for $600 that is as good or better than one that would cost $3000, why should I mourn the days of tiny pins and springs and assemblers who went blind working under gas lamps?

Jim

Some of the folks might have noted my post on the Ladysmith I acquired. At the time I did the pictures, I thought I had misplaced the upper side plate screw, but it turned out it had been missing before I bought the gun.

I found out that (believe it or not) the upper sideplate screw for a pre-Model 10 will fit the Ladysmith. Those screws are like gold these days, but I did get one and only had to shorten it a bit because the Ladysmith frame is thinner. I couldn't get a nickel plated one, so I took off the blue and it looks, not really OK, but not too bad.

Looking at the lockwork of the Model 1899, it is amazing that S&W has managed to make such a large number of improvements without (up to the "lock") changing their basic frame outline and shape. The aim has always been to improve and simplify the lockwork, while keeping costs down. (Some would say "making it cheaper" but what is really wrong with that?) I can't see that any of those changes made the gun less reliable, less accurate, or less functional. Some folks may get all bothered about using coil springs or MIM parts, but if I can buy a gun for $600 that is as good or better than one that would cost $3000, why should I mourn the days of tiny pins and springs and assemblers who went blind working under gas lamps?

Jim