stagpanther

New member

I finally had a bit of spare time to get back to the 270 win project and finish it off.

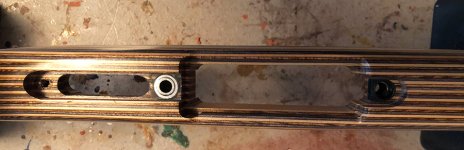

I decided to mill out the front pillar area up to the lug cut-out and make a nice solid block of plastic steel while also bedding the action. I also added a steel pillar for the rear action screw.

Since I started this project--I also bought a Boyd's keyhole stock to compare this one to--the over-all finishing--both inside and out in the Keystone stock is IMO significantly better to that of Boyd's. They both required some working to get a precise fit--but the Keystone seems to be the better machined of the two. That said--on the Keystone stock I bought--which is insetted for a savage axis--the inlet for the trigger appears to have been cut for a 110/111--the rear screw hole on an axis trigger guard overhung void. A little bit of milling of the back of the inlet to accommodate a 110/111 trigger guard and problem solved. The only other inlet issue with the Keystone stock that is a bit annoying is that the magazine inlet is cut low fairly deep into the stock--so getting the magazine in and out is a bit of work.

I decided to mill out the front pillar area up to the lug cut-out and make a nice solid block of plastic steel while also bedding the action. I also added a steel pillar for the rear action screw.

Since I started this project--I also bought a Boyd's keyhole stock to compare this one to--the over-all finishing--both inside and out in the Keystone stock is IMO significantly better to that of Boyd's. They both required some working to get a precise fit--but the Keystone seems to be the better machined of the two. That said--on the Keystone stock I bought--which is insetted for a savage axis--the inlet for the trigger appears to have been cut for a 110/111--the rear screw hole on an axis trigger guard overhung void. A little bit of milling of the back of the inlet to accommodate a 110/111 trigger guard and problem solved. The only other inlet issue with the Keystone stock that is a bit annoying is that the magazine inlet is cut low fairly deep into the stock--so getting the magazine in and out is a bit of work.